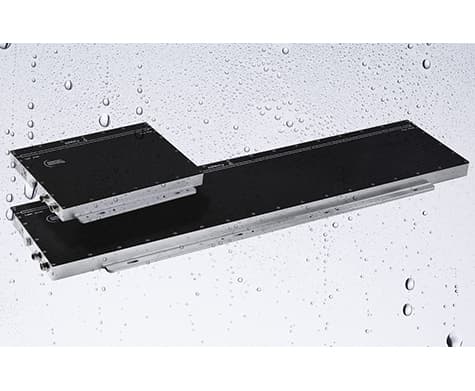

The expanded X-Scan T camera family addresses a wide range of industrial inspection needs with four new variants of the TDI-based (Time Delay Integration) product family. Available in lengths of 307 mm, 512 mm, 614 mm, and 820 mm. The X-Scan T is built on a modular platform that is easy to scale for a variety of X-ray imaging needs. The product family provides high sensitivity with a low X-ray dose. As a result, image quality meets the most stringent requirements of industrial applications. It also reduces the required X-ray power and doubles the detector lifetime under X-ray when compared to the industry average. Furthermore, the low-dose operation mode enables the minimization of shielding of X-ray systems, generating total cost savings and streamlining system designs. The series features a scanning speed of 180 m/min.

X-ray camera addresses industrial inspection needs