DECember 2022

The audience has spoken.

These are the new plant products that FE readers were most interested in for 2022.

Video courtesy of Getty Images / xleviathanx

From November 2021 to November 2022 we’ve covered the launches of many innovative new plant products hitting the market—472 articles to be exact. All of us at FE wanted to look back at these products to find the top 10 most impressive and eye-catching machines, energy solutions, AI technology and more. This list was created by compiling all 472 articles and comparing web views to find which ones were worthy of such a title. In a sense, you, the reader, have helped create this list by your interest in these products and companies. Without further ado, here are the top 10 new plant products of 2022.

The FP605, an industrial fan and pump drive, is designed to reduce energy use, including centrifugal compressors, fans, pumps and process control in industries such as material handling, food and beverage, and more. Image courtesy of Yaskawa America, Inc.

#10

Yaskawa America, Inc.

Industrial Fan & Pump Drive

The FP605, an industrial fan and pump drive, is designed to reduce energy use, including centrifugal compressors, fans, pumps and process control in industries such as material handling, food and beverage, and more. It builds on the success of its predecessor, the P1000 AC drive. This model’s portfolio Includes:

• IP20/UL Type 1: 3 to 60 HP @ 240 V; 3 to 125 HP @ 480 V

• IP20/Protected Chassis: 75 to 150 HP @ 240 V; 150 to 600 HP @ 480 V

• IP55/UL Type 12: 3 to 40HP @ 240 V; 3 to 100 HP @ 480 V

• IP55/UL Type 12 with Switch: 3 to 40 HP @ 240 V; 3 to 75 HP @ 480 V

The machine is designed for reliable soft tissue separation of meat, poultry, fish and more. Image courtesy of Provisur Technologies

#9

Provisur Technologies

Soft Tissue Separator

This belt separator is designed for reliable soft tissue separation of meat, poultry, fish and more, and it can be optimally integrated with other food processing components from the Provisur portfolio. It's designed for efficient separation of meat, poultry or fish bone fragments, tendons, cartilage and more while preserving the integrity and structure of the food. It can also be used for the clean separation of components in products such as fruit and vegetables. In addition, it is suitable for depacking: when processing defective articles or those whose best-before date has passed, it separates product and packaging.

Equipped with frequency control, the STS regulates process speed and matches it to other upstream or downstream line components. The unit features a contemporary, hygienic design with a removable or replaceable belt, thus enabling quick and easy cleaning and maintenance. The STS can be used as a standalone machine or integrated into a line. With capacities ranging from 500 kg/h to 3.6 t/h.

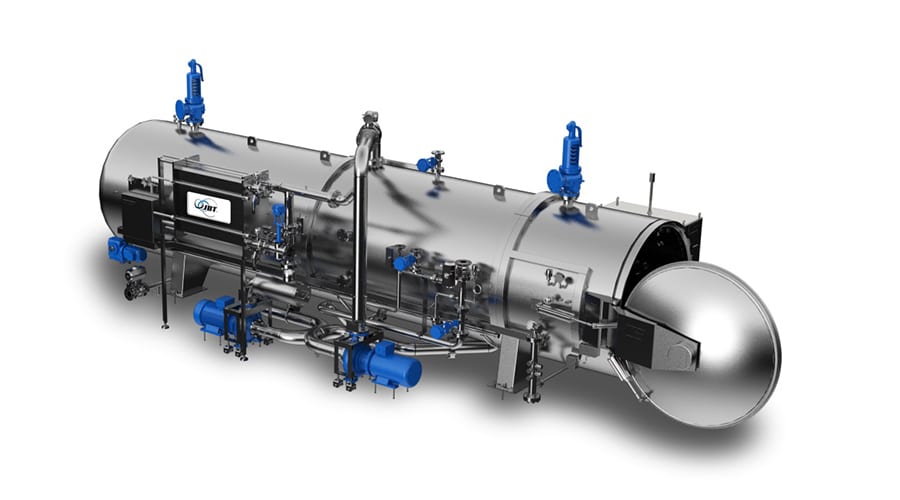

Designed to sterilize an array of food and beverage products, the SuperStatic Retort is equipped with enhanced heating and cooling technology to ensure uniform and efficient thermal processing of shelf-stable products. Image courtesy of JBT Corporation

#8

JBT Corporation

SuperStatic Retort System

The SuperStatic Retort is a stainless steel retort solution designed for reduced process times, energy consumption, floor space and more. The company says that its solution achieves target food safety and shelf-stability objectives with lower costs and greater productivity.

Designed to sterilize an array of food and beverage products, the SuperStatic Retort is equipped with enhanced heating and cooling technology to ensure uniform and efficient thermal processing of shelfstable products. Customers also benefit from steam and water savings, while maximizing product throughput with the SuperStatic Retort’s unique features, the company says. Initial tests of the technology reportedly showed come up time reductions of up to 30% and cooling time reduction of up to 34% for convective products.

Users can expect to see accelerated IQ Sensor reporting of static measurements to the Control Station. Image courtesy of Simco-Ion

#7

Simco-Ion

Sensor Priority—V7.5 Control Station

Simco-Ion released the Control Station V7.5, now allowing for Sensor Priority. With firmware advancements, users will see accelerated IQ Sensor reporting to the Control Station. In addition to the refresh on the screen, data and error messaging are also updated to the PLC via interface modules such as Ethernet IP or Modbus, along with the traditional relay outputs for fault and warnings utilized by all devices on the Control Station network.

The IQ Power HL Sensor offers real-time static measurements in Class 1, Div. 1 hazardous environments. The HL Sensor can operate with an IQ Neutralizer in closed-loop feedback mode or as a standalone static monitoring system. A secure digital communication and a unique data verifying algorithm is designed to build on the device calibration to deliver accurate, repeatable and reliable information and thereby avoid measurement error and costly false alarms.

The new fruit sorter is powered by Google AI. Image courtesy of Sunkist Research and Technical Services

#6

Sunkist Research & Technology Services

Citrus Fruit Sorter

Sunsortai machine, a next-generation sorter from Sunkist Research and Technical Services, is a sorting and grading machine for citrus fruit. It uses Google AI technology to assess the inherent quality of each piece it processes, including any potential defects. Through repetition, the sorter learns to distinguish a defect's appearance from normal anomalous features like blossoms and stems.

The Sunsortai uses a proprietary imaging system to automatically identify fruit characteristics such as size, shape, weight, blemishes and even decay that might not be visible to the naked eye. Be it citrus greening, oleocellosis or citrus cankers, the sorter can be trained to recognize the blemishes and defects that matter the most to each packer's operation. The machines can be customized to serve to each facility's individual needs and it will readily adapt to existing conveying systems.

PPS offers continuous and batch mixing and blending systems focused on consistency and repeatability. Image courtesy of Powder Process Solutions

#5

Powder Process-Solutions

Powder Mixing & Blending Systems

PPS offers continuous and batch mixing and blending systems focused on consistency and repeatability. PPS engineers analyze material and powder properties to determine optimal blend time, batch volume and rotor design that provide a consistently homogenous blend and high throughputs. The company will also evaluate product degradation, heat build-up and other potential concerns. PPS says that its experience with upstream and downstream process requirements, and rigorous sanitation standards, enable it to properly select and integrate the necessary equipment in new or existing designs.

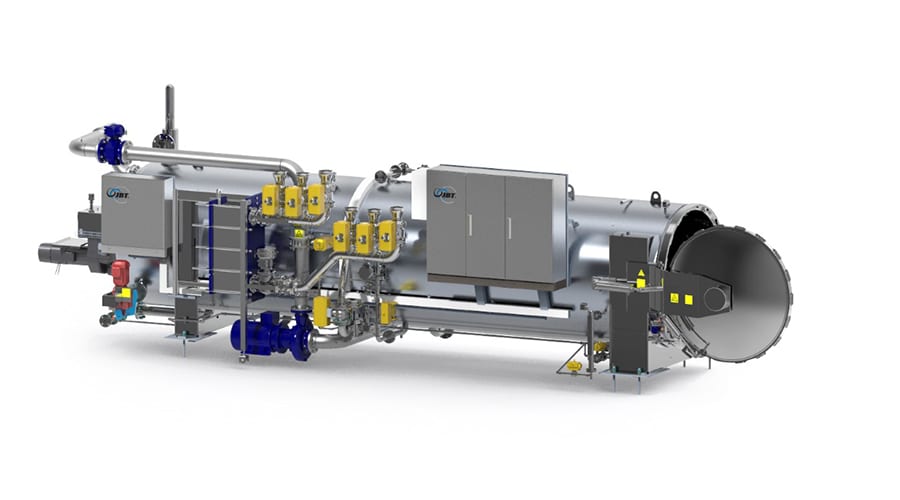

JBT Corporation's Energy Recovery System integrates with new and existing JBT Steam Water Spray retort systems. Image courtesy of JBT Corporation

#4

JBT Corporation

Energy Recovery Steam Water Spray Retort system

Designed to seamlessly integrate into new and existing JBT Steam Water Spray (SWS) retort systems, SWS says its updated ERS technology allows customers to benefit from additional cost savings and up to a reported 30% energy savings, without extending thermal process cycles. Using hot- and cold-water tanks that transfer energy between the come-up and cooling portions of the retort’s thermal process, the ERS extracts energy during the cooling phase. This energy is then utilized for heating during the come-up phase.

The companies aim to create specialized sealing technology for Hyrdact’s water-hydraulic process valves for us in the brewing and liquid processing industry. Image courtesy of Hydract

#3

Hydract & Freudenberg Sealing Technologies

Water-Hydraulic Process Valves

Hyract and Fruedenber’s three sealing solutions are design to be fully functional over a long service-life. They are designed to offer resistance to extreme pressures, meet hygienic design standards and have properties for use in the beverage industry. With a tailored hygienic design, all three seals offer high-pressure resistance from +5-°C to +140-°C, pressure resistance from 0 to 10 bar and a long service life. The materials used have received the relevant approvals and were subjected to the conformity tests according to EG (Reg.) 1935/2004, EU (Reg.) 10/2011, FDA and 3-A Sanitary Standards.

The new design from SPX FLOW is intended to offer dairy, personal care and plant-based processors a higher level of hygiene and food safety. Image courtesy of SPX FLOW Inc.

#2

SPX FLOW Inc.

Aseptic Rapid Recovery System

The product is intended to offer dairy and plant-based processors a sustainable way to increase productivity, reduce waste and provide greater product. SPX FLOW's recovery system aims to save more high-value product through a quicker cleaning process. It can also be used for other high-viscosity products, including creams, cosmetics and nutraceuticals.

The Aseptic Rapid Recovery System is designed to clear product from process pipes in a more sustainable way—using approximately 60% to 70% less water compared to other cleaning systems.

Along with Everactive, the company supports decarbonization with wireless technology that harvests its own energy, significantly reducing wasted energy and excess emissions. Image courtesy of Armstrong International

#1

Armstrong International

Batteryless Strap Monitors

Along with Everactive, Armstrong International supports decarbonization with wireless technology that harvests its own energy, significantly reducing wasted energy and excess emissions. Everactive monitors require no batteries so there is no maintenance to replace them. They work with all makes and models of steam traps and connect directly to the company’s SAGE management system to deliver real-time insight into a company's entire steam trap population. By receiving alerts of trap failures as they occur, technicians are able to repair or replace failing traps before they create serious steam system issues.

DecEMBER 2022