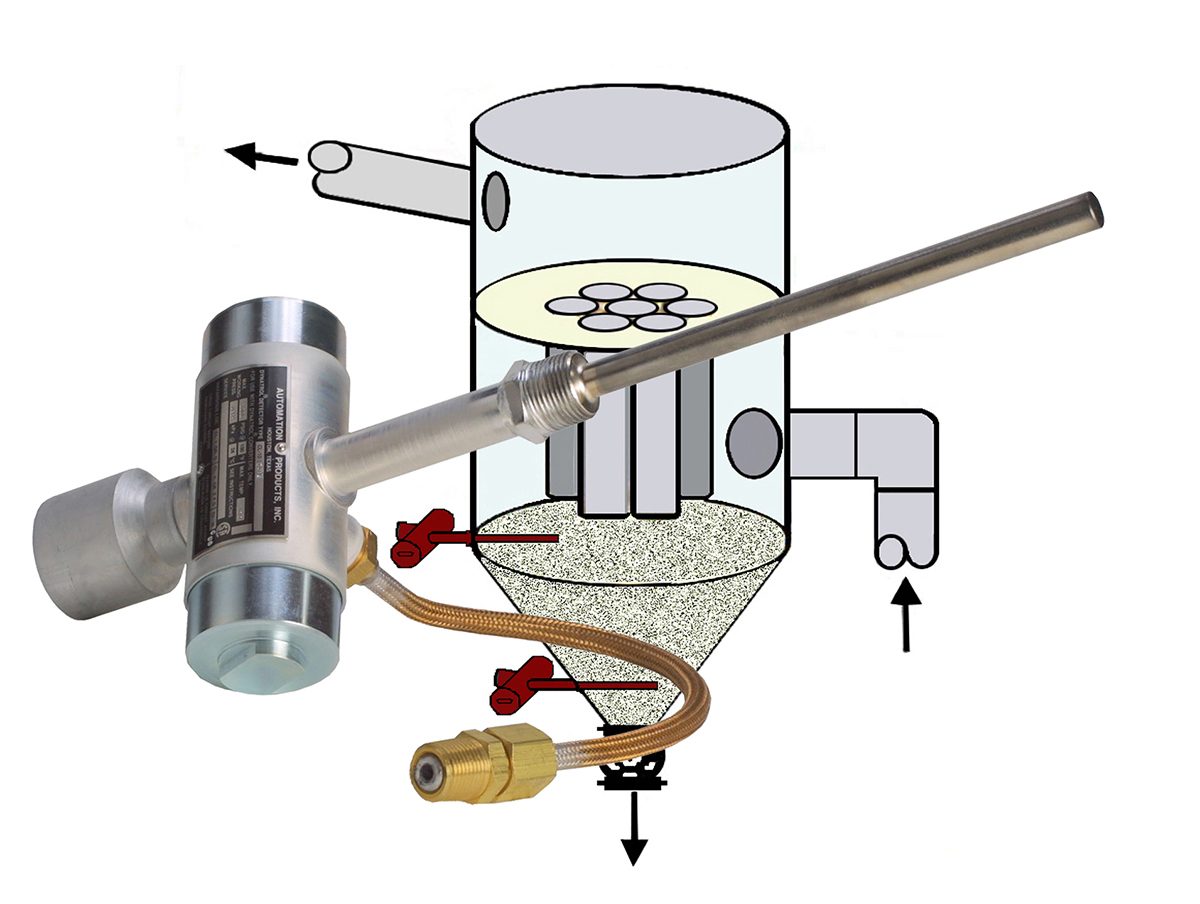

The Dynatrol DJ Level Switch provides either high or low point level detection of bulk solids. The detector operates on applications such as baghouses, cyclone separators or above airlocks, while achieving consistent results on flour, powdered sugar, cocoa, seasonings and many other granulated materials. These durable level detectors contain no moving parts, gaskets or seals and rely on mechanical oscillations to determine if the probe is covered or uncovered. It also works in dusty environments and vessels equipped with vibrators. This level switch is approved for Class III services, as well as for Class I, Groups C & D; Class II, Groups E, F & G; Class III approved. The level switch is mounted through a 3/4” half-coupling at the point of desired level detection. Dynatrol detectors require no adjustments and are virtually wear-free.