The number of handwashing stations at facility entrances should be sufficient to ensure workers will wash their hands and not bypass the stations. Photo courtesy of Getty Images/andresr

When the COVID-19 pandemic started, handwashing and sanitizing was one of the preventive measures adopted throughout the world as a means of slowing the spread of the virus. Scientists had not yet determined that COVID-19 was a respiratory virus and not spread through hands or food. Since handwashing is a key element of the food quality and safety programs for food processors, meeting this early mandate was not a major issue for the industry. But how should companies go about ensuring that their people not only wash their hands, but that handwashing is effective?

There are four basic elements processors should include in their handwashing:

• Developing and documenting the procedure

• Education

• Establishing and properly locating handwashing stations

• Monitoring and maintaining the program

These four elements are not “stand-alone” points but they must be viewed as part of a systematic approach to proper handwashing. As an example, one cannot draft procedures without knowing equipment, and well-documented protocols are an essential element for training and education.

The first step of a handwashing program is developing and documenting how workers shall wash their hands and how the program will be managed. These procedures must be based on the handwashing equipment the company has adopted. A standard procedure might consist of the following:

1. Wetting hands with warm water

2. Washing with soap for at least 20 seconds

3. Rinsing the soap with warm water

4. Drying hands using clean towels or an electronic hot air dryer

5. Apply a sanitizer (optional)

Often overlooked, but vital for safe food handling and processing, here are some strategies for implementing a handwashing program in your operation

Getting handwashing right

The protocols that are drafted must describe how the workforce should use the handwashing equipment. To minimize potential contamination of hands and enhance handwashing efficiency, it is recommended that handwashing stations be hands-free. If workers have to manipulate spigots or taps, these must be touched before and after washing, and what was on the dirty hands may be transferred to the tap and back to the hands. Procedures must be clearly written so they may be easily understood by workers and trainers.

Education and training

Workers must be educated using the documented protocols. The trainers must never deviate from what was written. Handwashing should be an integral element of a company’s orientation for new employees and the yearly refresher sessions. These sessions, especially for new hires, should include a practical element, where every participant has the opportunity to wash their hands using all the different handwashing options in the facility.

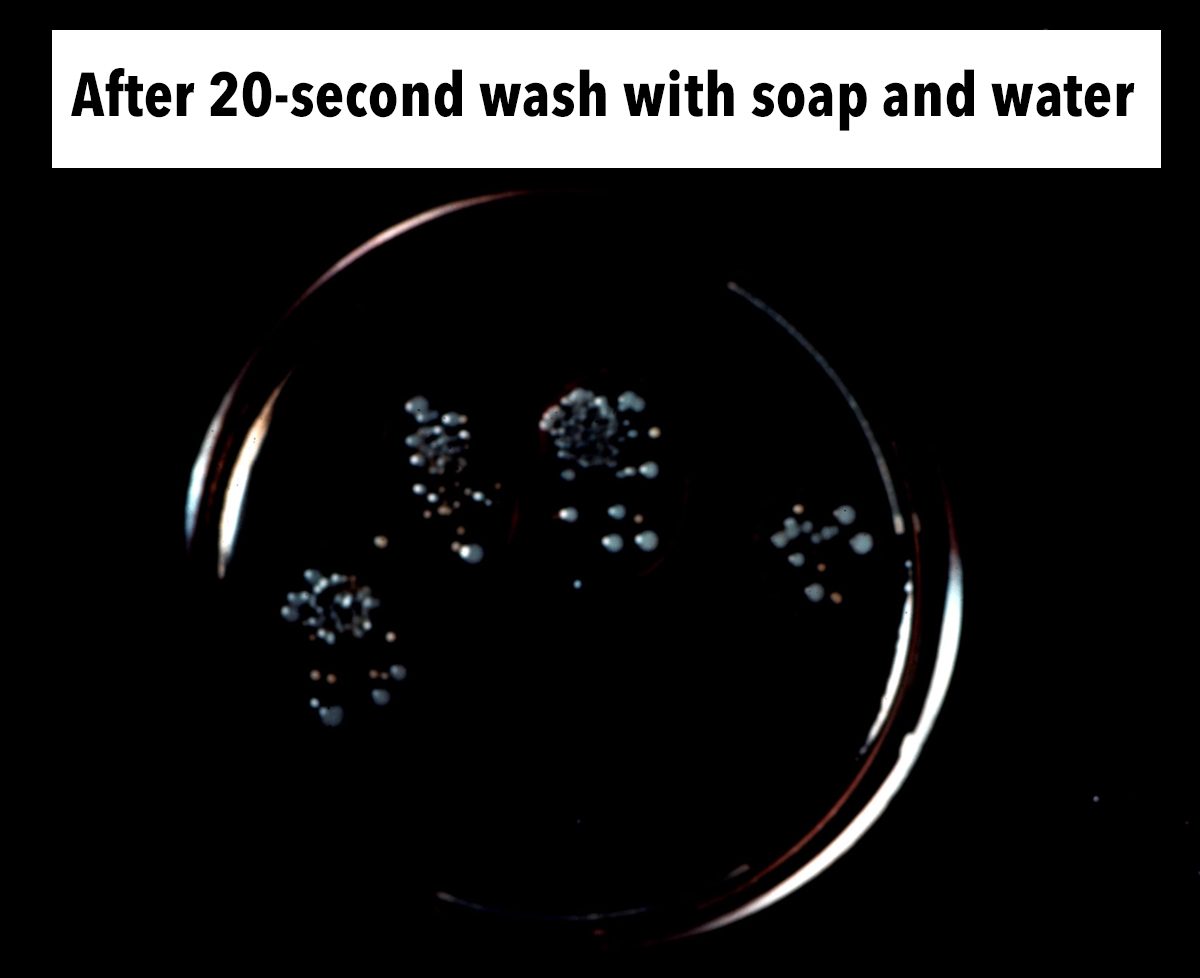

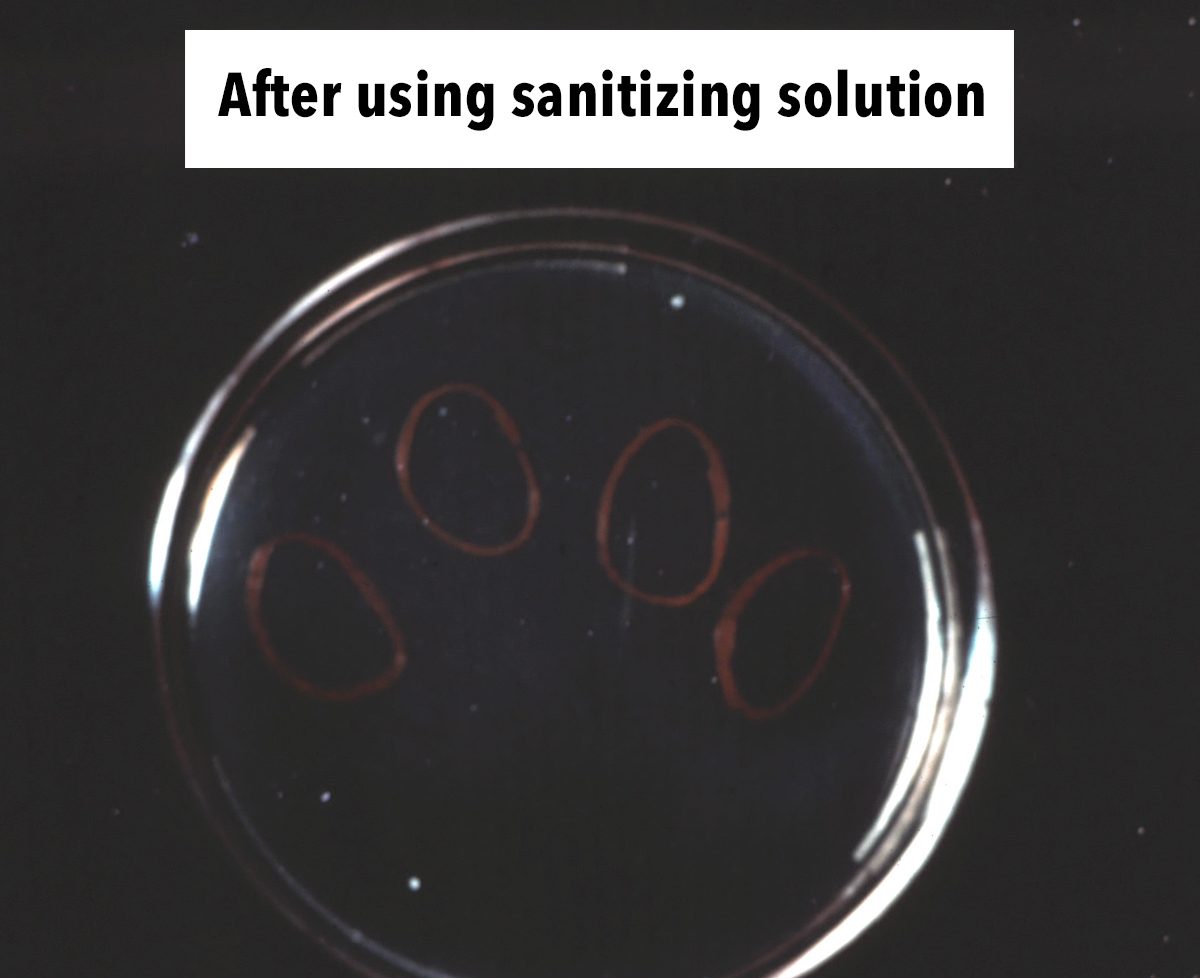

These sessions must also emphasize the importance of handwashing for ensuring the production of safe food. Since many plant workers have little understanding of basic microbiology and foodborne illness, the sessions should also be designed to provide some background on these subjects. One excellent tool used by many companies are the petri dishes/plates with media to demonstrate that hands do contain bacteria and how handwashing and sanitizing can remove those organisms. Ask workers to touch petri dishes with the tips of their fingers. Ask the same people to wash and/or sanitize hands and touch a plate. Bring the group together later to view the media so they can see the results.

Another excellent tool for processors are the products manufactured by GLO-GERM. One product is a fluorescent powder that can be placed on hands. The powder is transferred to any surface or person he or she touches. Using an ultraviolet light, the places touched by the person will fluoresce, demonstrating how bacteria may be spread.

The company also manufactures a cream that fluoresces. Ask one or more of the participants to rub the product into their hands as they would a hand cream and then have them wash their hands. Once they have finished washing up, turn out the lights and shine the ultraviolet light on their hands. Any residual cream will glow indicating that the person did not wash properly.

These sessions must also emphasize when workers wash their hands, that is, at the start of the work day, after breaks and meals and whenever they may have soiled their hands such as moving a trash bin. The bottom line is that workers may end up washing their hands between 5 –10 times per day.

One excellent tool used by many companies are the petri dishes/plates with media to demonstrate that hands do contain bacteria and how handwashing and sanitizing can remove those organisms.