FEBRUARY 2022

TRACK AND TRACE

The Case for

Why food processors can’t afford to be without this technology in 2022

Current supply chain woes have made nearly every aspect of processing an ongoing guessing game, from forecasting ingredient availability to ensuring finished foods arrive at their destinations on time. One way to help make sense of the situation is to invest in track-and-trace (T&T) technology that can monitor every step of a product’s journey through a plant and beyond.

“Operating a food processing business today without T&T technology is like driving blind down a highway in the dark,” says Louis Columbus, principal at DELMIAWorks. “Any existing facility without track and traceability is at a competitive disadvantage, because the data-driven insights it provides are exceptional compared to operating without it.”

Whether you already have some elements of T&T technology in your facility tied into ERP and MES systems and want to expand it, or you’re looking to add that functionality for the first time in 2022, here are some of the reasons why it’s a smart move for your company to invest in T&T technology.

Michael Costa, EDITOR-IN-CHIEF

Pod Pack uses track-and-trace technology to log the production of K-Cups at its plant in Baton Rouge, Louisiana. Photo courtesy of Pod Pack

"From the moment materials enter the facility until the finished product departs," explains Omron's Eric Henefield, "every production step, quality check and process control point is monitored and stored together with that product." Photo courtesy of Omron

What exactly is track and trace?

“The terms ‘traceability’ or ‘track and trace’ is something we hear often within the Industry 4.0 domain,” explains Eric Henefield, director, traceability business at Omron. “For a food processor, this means tracking everything within the manufacturing and/or packaging facilities by assigning unique identifiers and serialization. From the moment materials enter the facility until the finished product departs, every production step, quality check and process control point is monitored and stored together with that product. This can include any data involved during production, including temperature, ingredient recipes, cooking and cooling, station sanitization and more.”

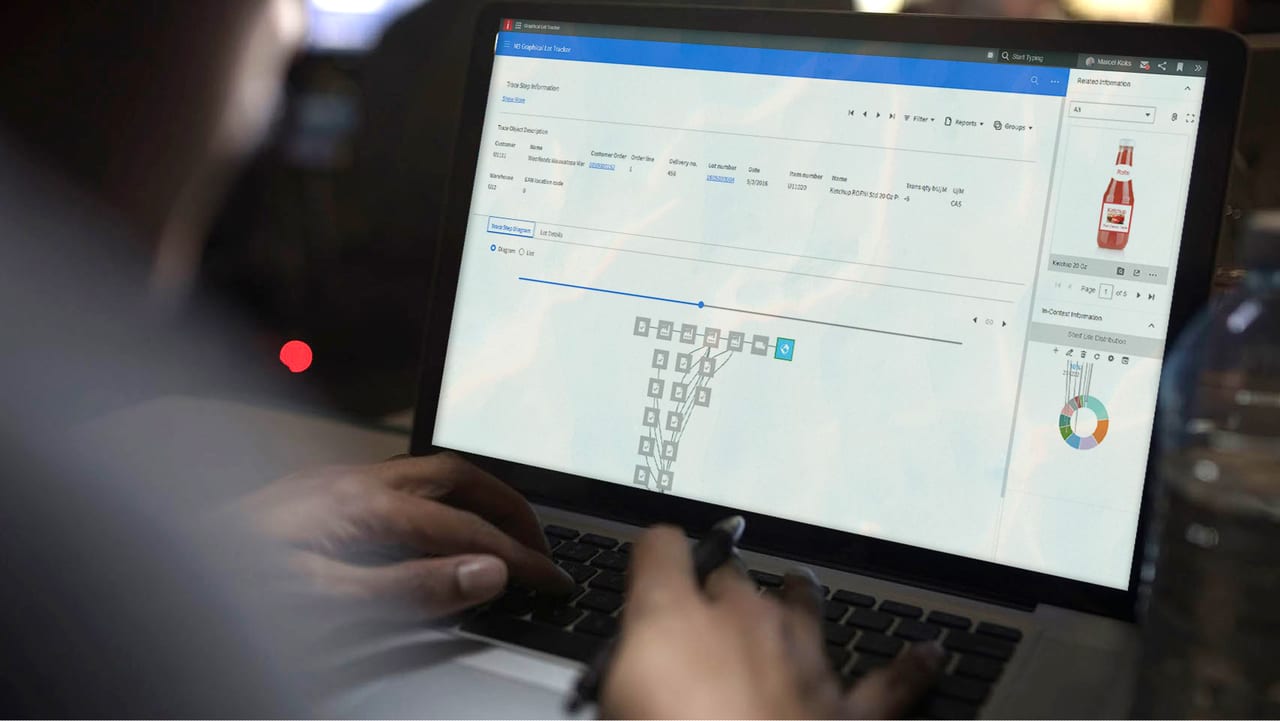

Marcel Koks, industry and solution strategy director, F&B at Infor, adds, “It’s of growing importance to not only capture the transactions within the enterprise, but also capture information from upstream in the supply chain all the way to the farm. It’s important that the consistency of transactions is being monitored to avoid broken T&T links, for example, because an ingredient may not reported as consumed on a production order, or because someone simply booked a stock correction and created stock of a finished product without any consumed ingredients.”

Reduce recalls

One of the foundational functions of T&T is to help reduce the number of product recalls due to food safety issues, as well as diminish the time needed to identify and pull those products, a process that T&T technology can speed up before those items hit store shelves.

“T&T can reduce the expense, impact and risk of product recalls by having accurate genealogies of each product available in real-time,” Columbus explains. “Minimizing the impact of defective or spoiled ingredients by tracking to the lot, batch or bin level where a defective ingredient originated from can save millions of dollars in product recall costs. Using genealogies to discover how a defective ingredient was first introduced into production is invaluable. With a given product or recipe’s genealogy recorded, it’s possible to isolate finished products at risk and make more informed decisions regarding how best to handle the products already with customers.”

"It’s of growing importance to not only capture the transactions within the enterprise, but also capture information from upstream in the supply chain all the way to the farm," says Infor's Marcel Koks. Photo courtesy of Infor

FDA compliance

Another area of food safety where T&T can help in 2022 is with FDA compliance regulations. “The FDA is currently in process of updating the existing FSMA (Food Safety Modernization Act) with additional guidelines. The new initiative, named ‘New Era of Smarter Food Safety’ is designed to prevent and mitigate foodborne illness outbreaks. At the core of this new directive is the requirement for all food processors to maintain records of KDEs (Key Data Elements) associated with CTEs (Critical Tracking Events) within their production facilities,” Koks says.

While effective T&T solutions can ensure FDA compliance, several side benefits exist when it comes to audits as well. “Customer-based audits that occur every 90 to 180 days are sometimes more rigorous than some of the regulatory reporting requirements, and having an automated system to streamlining reporting and audit preparation saves a quality management teams hundreds of hours a year,” notes Columbus. “T&T technology is essential for food processors to stay in compliance with FDA 21 CFR Part 11 Compliance (Doc Control, Quality Level 1), plus receipt management reporting, batch and ingredient tracking, quality assurance—including SPC/quick inspection—recall tracking, employee training tracking, seasonal demand forecasting and many other initiatives.”

Thwarting theft

T&T technology may be primarily associated with ingredient and product monitoring, but it can also help pinpoint where and when those products may have been stolen. “T&T technology reduces inventory shrinkage and theft due to greater visibility and real-time reporting that quickly catches inconsistencies in inventory levels. When a track and trace system is managing all inbound shipments to the batch, lot, and container level, it’s relatively easy to see at what point inventory is lost or stolen,” Columbus says.

“Operating a food processing business today without track-and-trace technology is like driving blind down a highway in the dark.”

—Louis Columbus, principal, DELMIAWorks

Facility compatibility

Both new-build and existing processing facilities can benefit from adding T&T technology, although greenfield projects can incorporate that technology directly into the building design, while operating facilities often have to work around existing elements.

“Existing facilities have an infrastructure of equipment and systems that must be accommodated,” says Henefield, “and these existing factories are also up and running, usually pushing maximum production capabilities. Creating downtime to implement new solutions can be very challenging. Implementing the proper traceability solutions into the design from the beginning is a much smoother path to success.”

Consumer demand

Processors aren’t the only ones interested in tracing the origins of ingredients and finished foods. Consumers have also increasingly demanded to know where their food is sourced, and T&T data can be used to satisfy that demand.

“Blockchain is an interesting technology for this, because it ensures information cannot be manipulated once it’s in the ledger. GS1 Digital Link makes it possible to print QR codes on the packaging, so consumers can scan this to see the origin of the food. The world’s largest producer of Atlantic salmon is using this technology so consumers can get the full story, from the aquaculture farm to the packaging at hand. For some F&B categories, like expensive spirits, we see digital tags that support T&T, but with the purpose to unmask fake products,” observes Koks.

Both new-build and existing processing facilities can benefit from adding track-and-trace technology, although greenfield projects can incorporate that technology directly into the building design. Photo courtesy of Pod Pack

Connecting the digital dots

There isn’t one single plug-and-play solution for processors when it comes to adding T&T technology, but that tech is flexible enough to integrate into existing data collection tools within a facility—like ERP and MES—before connecting that data into a wider database.

“Every food processing business model is different in how they adopt, implement and fine-tune T&T technology,” notes Columbus. “It’s important to keep T&T in the context of how much value it delivers outside the four walls of a processor’s production center, with data captured in supply chains, from suppliers and from tracking shipments in transit, assuring their freshness, quality and security.”

Koks concludes that, “the production process also impacts how precise T&T can be. In beef processing, a piece of meat can, in principle, be linked to the animal, but this is not possible when working with milk in tanks. The milk of multiple farms is already blended in the truck at collection, so the level of detail in T&T impacts cost. For example, you can blend fewer separate milk lots in a tank, but then you need to empty and clean tanks more often and probably need to acquire more tanks too.” FE

FEBRuary 2022