Broken glass must be properly cleaned up and disposed of to avoid contaminating food and beverage products. Photo courtesy of: Floriana via Getty Images

There are many different foreign materials that could and actually have ended up in foods. The most insidious of these and the one most feared is glass, as it has the potential to injure people in different ways such as cracked or broken teeth and cuts. This is the main reason that most companies have a distinct documented protocol within their foreign materials management program called “Glass and Brittle Plastic.”

The Hazard Analysis and Critical Control Point (HACCP) program mandates that food processors determine potential biological, chemical and physical hazards that are “significant” or “reasonably likely to occur” and establish programs to eliminate those hazards or reduce it to an acceptable level.

The juice HACCP regulation found in 21 CFR Part 120 defines a food hazard as:

Any biological, chemical or physical agent that is reasonably likely to cause illness or injury in the absence of its control.

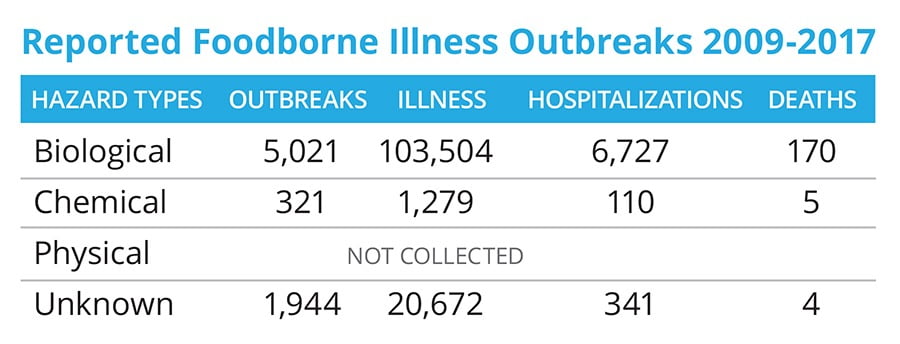

The regulations mandating HACCP throughout the world, and all other standards and guidance documents, focus on these three types of hazards, but it appears that the potential physical hazards may be getting short shrift. The following table is derived from data collected by the Centers for Disease Control between 2009 and 2017 and indicates that data for physical hazards was not even collected. Why was this not done?

How to successfully build your glass and brittle plastic program

Look sharp

Biological and chemical causes of foodborne illness outbreaks are tracked and reported, but physical causes are not. Data source: The Centers for Disease Control.

So, let’s look at what should be included a food processor’s glass and brittle plastic program. I have been working in the food industry for many years and have yet to see a company that did not need such a program. However, I have had several processors say “We have no need of such a program since we do not make glass-packed foods.” So, no lights, no gauge covers and no windows? The glass and brittle plastic program must address these and any other glass or plastic items that could potentially break and contaminate food products, beverages or ingredients.

The program must be developed, documented, implemented and maintained. The objective of the program should be clearly stated upfront: Minimize the potential for cross-contamination of foods and ingredients with glass or brittle plastic to ensure that foods and ingredients are safe and will not result in injury to end users.

The program should focus on more than food safety, however. The goal is to keep glass, brittle plastic and all other foreign materials out of foods; that is, minimize the potential for adulteration of foods since it is illegal to distribute foods that are adulterated. But, back to glass and brittle plastic. The program should be designed to ensure that not only the glass and brittle plastic that are in the production area do not get into food but that nothing could come into the plant that might create a problem. Company policy shall ensure that no glass or ceramics be carried into or used in the food processing area or warehouse at any time. These materials shall be confined to the offices and break area. In addition, watches must be removed before entering the plant and eyeglass lenses must be manufactured from shatterproof materials.

Glass containers such as bottles must be properly cleaned to remove any potential contaminants, including small pieces of glass. (Getty Images/ Sviatlana Lazarenka)

The first step in the process is to inventory and properly document all glass and brittle plastics in areas where foods and ingredients are stored or handled. This must include the warehouse, production and packaging areas. When conducting the inventory, the location of glass or plastic must be noted along with the type of glass or plastic (if possible) and whether it is shielded or strengthened in any way. When conducting this inventory, it must also include the area or areas where glass packaging materials are stored. This inventory must include all glass and brittle plastic, including but not limited to gauge covers, lights on fork lifts, lights, monitoring devices, clocks and thermometers. The materials being inventoried will vary with each and every food processing facility. It is a good idea to assign a number or some other designation to each item in the inventory. There is often more than one specific item in a room, and it is imperative that each and every piece in the inventory can be clearly identified. For example, if the warehouse has 50 overhead lights, make sure each is identified and appropriately flagged.

Once the inventory has been completed and is properly documented, the HACCP Team or another group should conduct a risk assessment on each item on the list. The objective is to determine whether any of the items in the inventory pose a significant risk to food safety or quality. Situations that pose a significant threat (high risk) shall be addressed as soon as possible and corrective actions noted in the master list. Corrective actions may include, but need not be limited to, the use of shields or covers on overhead lights, replacement of some plastics with those that are stronger or shatterproof, or removal of the item in question from the production or holding area. More and more processors are adopting shatterproof glass lighting in the operations, especially since long-life shatter-proof LEDs are now available. The inventory list will serve as the basis for regular audits of the glass and brittle plastic in the facility. If cracked, damaged or broken glass or brittle plastic is observed during audits, internal inspections, routine examinations of operations or during normal operations, it must be noted and evaluated immediately. Repairs shall be prioritized based on potential risk to the business. These incidents should be recorded in the glass breakage log. Note that the term “normal operations” is used. This implies that all persons in the plant are responsible for what goes on during process operations. If a line worker observes damaged glass or plastic or some other issue, he or she should report it to management. This also means that management needs to include glass and brittle plastic in the employee orientation and refresher training sessions.

Line workers should be trained to report damaged glass, plastic or other physical hazards to management.