Blockchain technology:

Is it ready for prime time?

While there have been many success stories, blockchain technologies are still developing, so producers and processors will need to examine their needs carefully

During the past couple of years, blockchain technology has become easier to implement for even small- and medium-size participants, thanks to large suppliers like IBM providing specific application-based blockchain technology (IBM Food Trust) and Amazon Web Services providing backbone networking architectures. In addition, smaller blockchain providers now have dedicated applications that can trace food not only to the farm and field in which it originated, but the very seed as well, while also providing complete supply chain visibility for all participants, including consumers.

You might consider blockchain’s “early days” to be about five years ago—when Walmart and IBM were first researching the viability of using blockchain in the food industry. Back then, large programming efforts were typically necessary to create a functional blockchain. Today, blockchain applications are becoming almost as easy to use as email.

In this article, we look at blockchain development and survey its practicality for processors—even small- and medium-sized food and beverage companies.

Wayne Labs, Senior Technical Editor

Penfolds has become the first winemaker to partner with BlockBar, a leading non-fungible token (NFT) marketplace for luxury wine and spirits products, which is based on a secure blockchain that guarantees purchasers a historical record of numbered bottles from a numbered barrel of wine. Photo courtesy of Penfolds

Blockchain highs and lows

You’ve no doubt heard that blockchain functionality can be used to secure supply chain operations and provide an immutable record of all activities from farm to fork, making the technology so highly practical for track and trace that FDA has been looking into its application for food safety. In addition, blockchain technologies can discourage theft and product tampering, as well as manage the tracking of lower-cost perishable food and high-end products like rare specialty wines.

Because Penfolds Magill Estate Winery in South Australia produced only 13 barrels of its vintage 2021 Shiraz Cabernet Sauvignon, the asking price is $130,000 for a single barrel—truly an investment. In fact, Penfolds has become the first winemaker to partner with BlockBar, a non-fungible token (NFT) marketplace using blockchain technology for luxury wine and spirits products, to launch a limited edition of its specialty wine. The digital token corresponds to this particular barrel currently maturing in Penfolds’ cellars.

The FDA announced winners of its “FDA New Era of Smarter Food Safety Low- or No-Cost Tech-Enabled Traceability Challenge,” which occurred this past summer. Out of 90 submissions from 90 unique teams, 12 winners were chosen, representing a range of technologies, including blockchain solutions. Image courtesy of FDA

The single barrel NFT will be converted into 300 bottle NFTs at the date of bottling of the wine in October 2022 with the whole process verifiable through the blockchain, and each bottle being identified with a barrel and bottle number. The NFT serves as a digital receipt that verifies the buyer’s ownership and authenticity of the wine bottles. The bottle NFTs can be resold or transferred through the BlockBar platform, and follow to the actual delivery of the bottle, which in this case is no earlier than the release date in October 2023.

In the FDA’s “New Era of Smarter Food Safety” document dated July 2020, FDA Commissioner Stephen Hahn said, “Our stakeholders should be looking at how to tap into new technologies that include, but are not limited to, artificial intelligence, the Internet of Things, sensor technologies and blockchain.”

In a recent FDA “New Era for Food Safety” public meeting, a presentation given by McKinsey & Company pointed out several public news releases where blockchain technologies are being adopted by food industry stakeholders. Some of these include:

• IBM’s Food Trust, which is bringing together food and agricultural companies on a blockchain traceability system.

• Walmart’s plan to require all U.S. spinach and lettuce suppliers to track products on blockchain.

• ADM, Bunge Ltd., Cargill and Louis Dreyfus companies are looking at ways to standardize and digitize global agricultural shipping transactions using blockchain.

• Alibaba has developed a blockchain-based Food Trust framework and has filed 90 patents on blockchain technology.

• Wipro joined the Blockchain in Transport Alliance, a member-based organization focused on transportation and logistics with applications in food and agriculture.

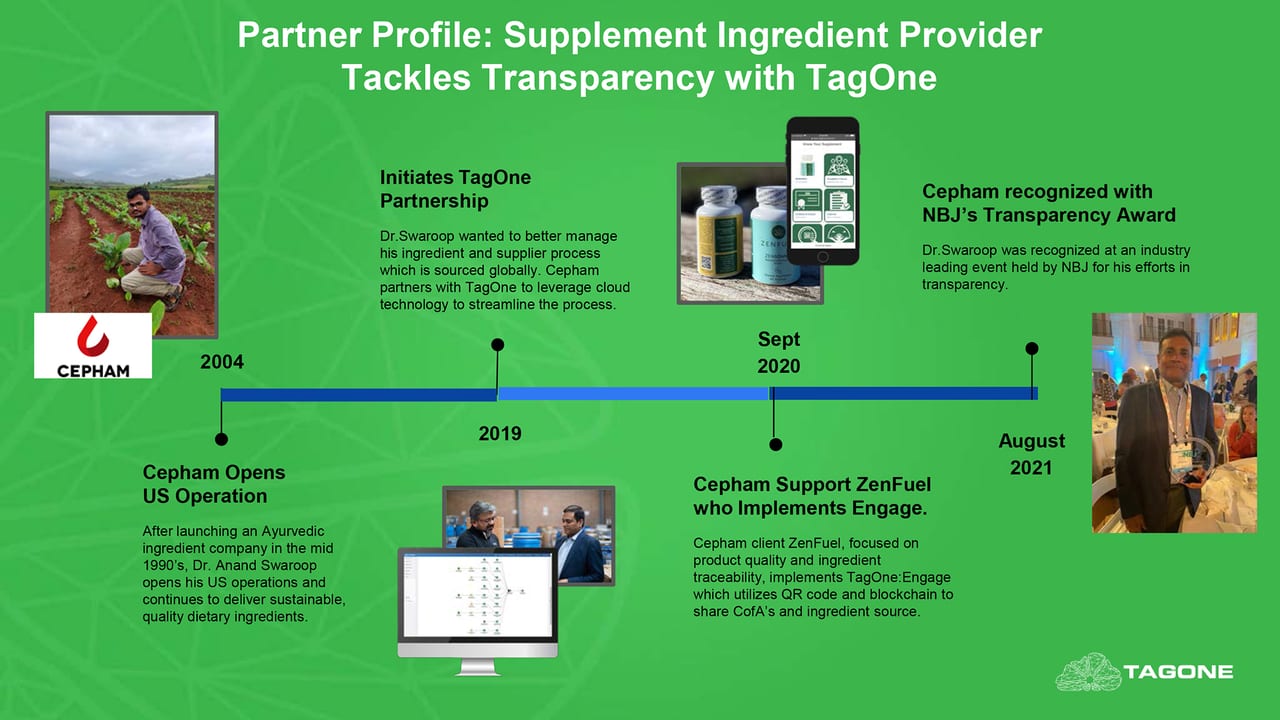

TagOne, a winner of the FDA’s Traceability Challenge, provided blockchain traceability tools for supplement ingredient manufacturer Cepham.

Simplifying blockchain systems—FDA gets involved

To spur interest in blockchain and other traceability technologies, FDA recently held its “New Era of Smarter Food Safety Low- or No-Cost Tech-Enabled Traceability Challenge.” Its purpose was to call on stakeholders—including technology providers, public health advocates, entrepreneurs and innovators from all disciplines and from around the world—to develop traceability hardware, software or data analytics platforms that are low-cost or no-cost to the end-user. [1]

The winning submissions covered a considerable range of use cases and consisted of a variety of approaches, platforms and technical designs. Twelve winning teams were identified, representing the U.S., Canada and New Zealand. Factors that identified top-performing submissions included practical solutions not requiring users to be technically proficient, demonstration of a solution that met a clear need in food traceability, integration with existing systems and a solution that reached all the way to the consumer.

Cost and connection issues

U+ is a tech consulting firm that provides a comprehensive set of services from ideation and market validation to product/software development and scaling. “Blockchain technology is slowly making an entrance into the supply chain process, but as it applies to the complexities of the food industry, its value proposition is still not clearly established,” says Jan Beránek, CEO and founder.

Even so, there are several key blockchain players in the food tracing technology space, namely IBM’s Food Trust, Ripe.io, FoodLogiQ and TE-Food, allowing consumers to verify the journey of their products, says Beránek. “Due to the complexity and varied needs of each customer, some level of customization and onboarding are still required; however, the process has been made smoother by the top players.”

“These blockchain technologies are already being utilized by many food processors. For example, TE-Food touts 6,000+ customers to track food from its origin to destination,” adds Beránek. “FoodLogiQ is working with big name customers such as Chipotle and Whole Foods on the consumer side, and Conagra and Tyson on the processor side. There are also blockchain companies working on other applications within the food industry, including crop insurance, financial transactions and supply-chain optimization, which could help level the playing field for smaller farmers and producers.”

Beránek suggests that blockchain technologies are rather costly at the benefit of providing a layer of security to the information on the blockchain, and many companies throughout the supply chain would need to align in order to benefit from such tracking. “Non-blockchain standards for safety and visibility of food supply chains such as GS1 currently exist, providing a certain level of compliance and tracking off-chain,” says Beránek. (For more on how GS1 standards and blockchain technologies can work together, see the sidebar below.)

Got blockchain: GS1 provides the data structures

GS1 provides a system of globally recognized data standards that is integral to business supply chain applications, such as event data, transactional data and even master data. The GS1 Standards bring structure and a harmonized format to the data being collected and used in a supply chain, so that different organizations are able to share and understand it. Without these standards, individual entities are left to operate within their own proprietary data systems and attempt to decipher the data they receive from one another. This silo approach to data management carries a high risk of errors and miscommunications that can impact supply chain visibility and optimization.

That’s important, since blockchain is being used in the food industry to make product recalls more efficient and to authenticate transparency claims. These benefits would be impossible if organizations could not readily share accurate product information, including its location and transactional events that occur during distribution. GS1 Standards help enable interoperability so the data is meaningful to all trading partners, which not only supports more efficient data exchange, it also helps the industry meet growing supply chain digitization requirements like the U.S. Food and Drug Administration (FDA) proposed Food Safety Modernization Act (FSMA) section 204 food traceability rule.

Think of blockchain as an immutable ledger for supply chain data that can safely live there in perpetuity, where authorized stakeholders can access and add to the information recording a product’s movement from origin to point of use. Pointers and hashes on the blockchain ledger can prove that the off-chain data was not tampered with.

Now think about the data that is so securely contained on the blockchain, and how it will be used. To enable product track-and-traceability (and facilitate efficient recalls when necessary), certain pieces of information are needed: specific details about the product, including unique identification, batch and lot numbers, and expiration date; and about all the touchpoints where that product has been handled through distribution, including locations and transactions like shipping, receiving, and more. To be useful, that data must be complete and accurate, updated in real time, and readily shared and understood by all trading partners up and down the supply chain.

That is where GS1 Standards come in. In particular, the GS1 Global Trade Item Number (GS1 GTIN) is a globally unique identification number assigned to an individual product; it includes the critical data elements mentioned above and is embedded in a barcode for scanning at every point along the way from farm or manufacturer to the store or restaurant where its journey ends. The standardized format enables interoperability by establishing a common language for data exchanged between trading partners. The food industry has been using GTINs for decades to identify products and facilitate track-and-trace capabilities.

Every facility that handles a product during distribution can also be uniquely identified using a GS1 Global Location Number (GLN), assigned by the facility owner and standardized for universal recognition. This prevents confusion that often results from different entities using their own proprietary systems or names for identification; when all stakeholders refer to products and locations in the same language, accuracy and efficiency are improved.

GS1’s Electronic Product Code Information Services (EPCIS) standard allows trading partners to capture and share information about the movement of products both within their enterprise and with their business partners. Such movements or “events” comprise four dimensions: What products are impacted? When did this time-stamped event occur? Where was the product? And, where is it now? Why was this observed, in which process step? Implementation of EPCIS makes it easier to track and trace products, manage inventory and satisfy regulatory requirements for accurate information on product chain of custody and availability.

A recent seafood industry pilot study demonstrated how GS1 Standards for product identification and data communication can help industry achieve interoperability among diverse proprietary traceability systems while leveraging blockchain, cloud or other technologies to optimize data sharing. The pilot was conducted by GS1 US in collaboration with the Global Dialogue on Seafood Traceability (GDST), the Institute of Food Technologists (IFT), Beaver Street Fisheries, Bumble Bee Seafoods, Chicken of the Sea, FoodLogiQ, IBM Food Trust, Insite Solutions/Norpac, ripe.io, SAP, Walmart and Wholechain.

Using real-world data, the pilot showed how EPCIS effectively enables recording of the what, where, when and why of supply-chain events, connecting multiple traceability systems. It clearly established the necessity of standards to identify products, entities, locations, critical tracking events and key data elements to support interoperability.

“The first thing we would do to help our customers is determine whether blockchain technology would provide adequate value for their supply chain and tracking capabilities,” adds Beránek. “In order to justify building or integrating a blockchain solution within their business, it would need to provide additional revenue, save costs, provide a competitive advantage or meet compliance requirements. If after the validation and market testing stages we determine that blockchain technology would indeed be beneficial for the current product, we would implement it in the system architecture.”

Connecting with ERP and MES

ERP systems can be standalone, or they can connect with blockchain systems. “Blockchain can be a promising solution to tackle the transparency and traceability challenge in the food and beverage industry; however, there are other solutions that compete with blockchain, such as ERP software that already enables end-to-end traceability,” says Maggie Slowik, IFS global industry director – manufacturing. IFS doesn’t offer a blockchain solution per se; however, it has strong industry-specific ERP software. This is part of the IFS cloud solution and helps manufacturers achieve end-to-end traceability by enabling the identification of all relevant data for the materials used in the production and distribution of finished goods, says Slowik.

Wholechain was named a winner of the FDA’s New Era of Smarter Food Safety Low- to No-Cost Food Traceability Challenge. When non-food items—such as perfumes—use food ingredients, traceability is as important as food. Aveda uses Wholechain to trace its vanilla ingredient from 450 farmers in Madagascar. The data informs the story behind the vanilla, accessible through QR codes printed on over 125 Aveda products. Image courtesy of Wholechain

“As the industry continues exploring blockchain’s potential applications, data standards will be vital to ensure interoperability for the information exchange it is intended to facilitate.”

— Kevin Otto, senior director, Community Engagement, GS1 US