UV sterilization technology works successfully in water treatment plants and HVAC systems, but milk and juices too?

Novel 'raslysation' technique works with non-clear/opaque liquids

Last year this column featured two methods of pasteurization that could be applied to liquid products, including milk and/or juices.(“Novel Pasteurization Technique Extends Shelf Life of Milk,” September 2021 and “Shear technology uses homogenization and ultrahigh pressure to improve quality, kill bacteria,” July 2021.) Both of these methods used novel ways of applying a short duration heat and/or pressure treatment to achieve an effective sterilization/pasteurization without changing the delicate flavors of the product.

This month is a look at a novel “raslysation” (the inventor’s name for roughly, a cold sterilization) technique that can be used to pasteurize milk and other non-transparent liquids. The sterilization process uses a newly patented ultraviolet (UV) source. The UV-based technology is claimed to use typically 90% less energy and more than 60% less water than traditional heating/cooling pasteurization processes. Sounds simple, but not so much. You may very well be familiar with UV light sources used to sterilize air flows in HVAC systems or to kill bacteria and other germs in water treatment systems, but to work in nearly opaque liquids seems a daunting challenge.

I must admit that I was skeptical at first, knowing that several attempts have been made for UV pasteurization of non-clear liquids in the past. Lyras, founded by CEO Rasmus Mortensen, got its start in Denmark (Northern Jutland) in 2017. Mortensen set out to prove that a sustainable non-thermal pasteurization process was possible, and that it could work effectively with these difficult liquids.

The research and development process behind this non-thermal pasteurization process took three years, but Mortensen—with the help of extensive consultation from a range of stakeholders in the dairy and juice industry, academia, health experts and specialists—proved the development of this non-thermal pasteurization process could be successful. Now, Mortensen claims that this technology can treat most liquid products, regardless of transparency and product type. I spoke with Mortensen to get a clearer picture of this UV technology.

Rasmus Mortensen, CEO, Lyras.

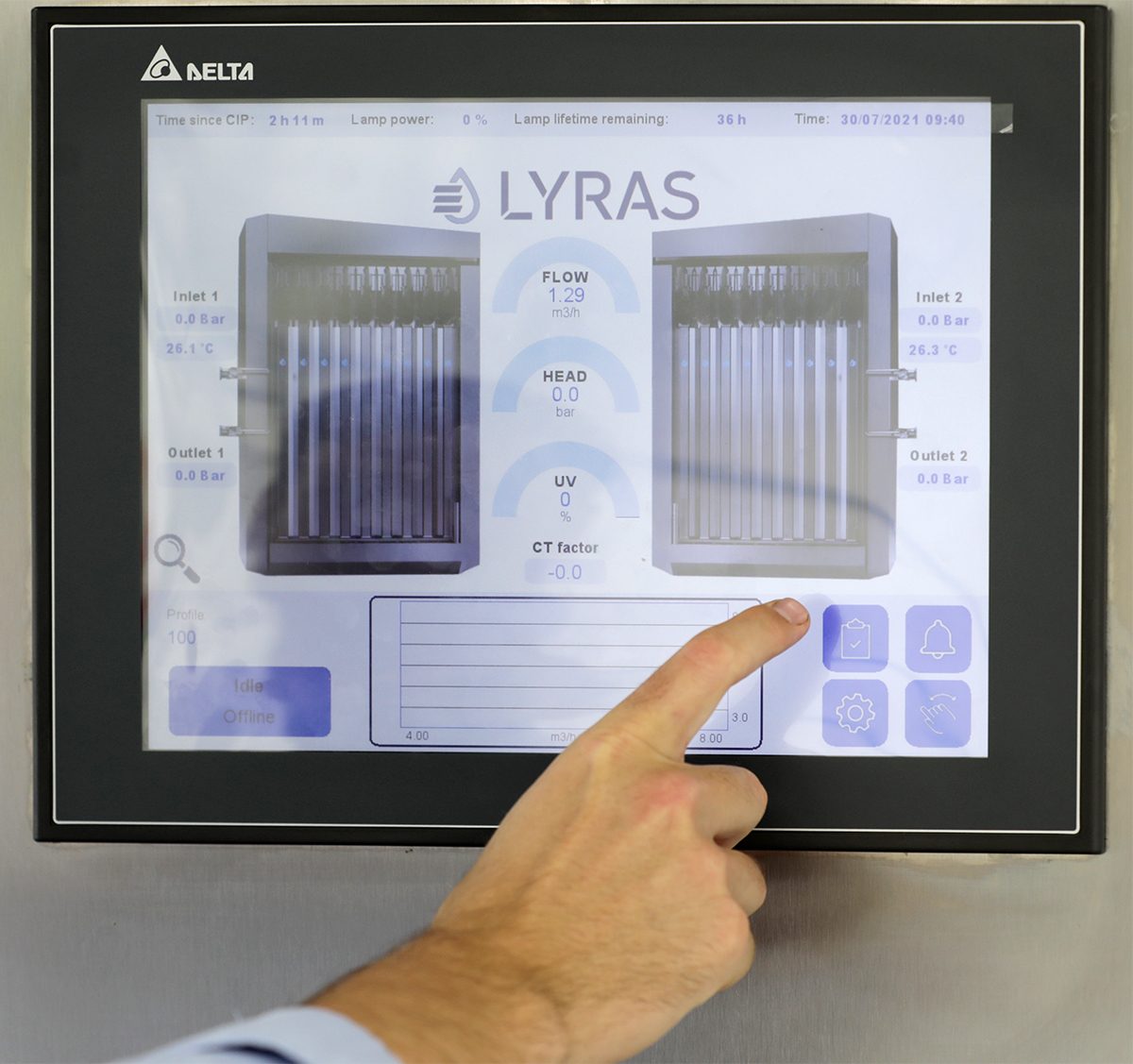

Control cabinet screen lets users make adjustments on the process. Photo courtesy of Lyras

Mortensen: I did all the wrong things. I started the company in my apartment and basically isolated myself for six months designing a commercial prototype. I didn´t reach out for any help on how to start a business, though I knew nothing about it. It was mind-bogglingly boring being alone in the apartment. 20/20 hindsight—I should have sought all the help I could have gotten. But I was too caught up in designing the system. However, after the first six months alone I started to network more and found my co-founders, who then joined Lyras, which was a blessing.

FE: How did you come up with this idea? What was your inspiration?

Rasmus Mortensen: During my studies as an environmental engineer, my master’s thesis was concerned with finding a new and sustainable treatment method for raw milk. During my project I applied several different known technologies—for example HPP (high-pressure processing) and PEF (pulsed electric field)—but I found that UV-light was what had the best effect while doing the least harm to the product being treated. I combined the UV-light with light filters, as I saw that some wavelengths had negative effect on the product quality. So I wanted to filter these wavelengths out to get the most gentle treatment possible.

FE: Once you had this idea of a UV cold pasteurization process, what help did you enlist to turn this idea into reality?

FE: Obviously, others have no doubt thought of applying UV to sterilize non-clear liquids in the past, but came up with some formidable obstacles to overcome. So what were the obstacles facing your development of a successful non-thermal pasteurization process?

Mortensen: Many have previously tried to solve these obstacles but have simply not tried the right combination of a turbulent flow in the liquid and a filter to assure that the entirety of the liquid was exposed to the UV-light, but only exposed just enough and by only the useful wavelengths.

In the past, many have given up because just as with heat, the more you treat the liquid, the more off-flavors develop.

If you do not assure that the treatment is done correctly, there will be some parts of the product that are over exposed to the UV-light and others that are not at all exposed. Thereby the products will no longer taste as good and the shelf life will not be very long.

That is where our raslysation technology has succeeded. It is the perfect combination of efficiency and gentle treatment that ensures that the product is perfectly treated every time.

FE: How did you overcome these obstacles?

Mortensen: I went into the lab and tried many different setups. None of them worked. In fact, I had to postpone my thesis by half a year to get it to work. Luckily, I finally struck gold, and I achieved a log-4 reduction in a new setup. I remember going to my professor’s office to tell him about the new results. He looked at me and said that when I first presented him the idea of my thesis project he thought that it was a very good idea, because it combined biology, chemistry and mechanical engineering so well. But he never thought I would get it to work.

FE: How is your process different than the UV used in HVAC and water sterilization systems? How to you get UV light to work effectively with these more opaque liquids?

Mortensen: A liquid such as milk is almost impenetrable by light. Therefore, by ensuring a constant turbulent flow, we can be certain that every little particle in the milk is carried out to the light source. What makes raslysation unique is the technology´s ability to treat opaque liquids without being able to shine the light into the liquid. Instead, we use a coil, and by utilizing the centrifugal forces, we get the particles to travel to the outer surfaces of the coil where they will be exposed to the light.

FE: It seems the technology uses less energy than other heating/pressure processes. Was this just serendipity, or was it your clear intent to make a pasteurization process that uses less energy than conventional heat/pressure-based systems?

Mortensen: I founded the company solely because I did an energy calculation that showed the enormous energy savings this technology brings to the table. Combining that with higher product quality and less water usage meant founding the company was really a no brainer. My biggest fear was that the technology would end up in a drawer at the university, never to be used.

The Lyras Model CPS can be used for highly opaque liquids with low UV-transmittance, which require light filter technology. Photo courtesy of Lyras

FE: How does your process work? What did you have to do make it applicable to non-clear/dense liquids?

Mortensen: We use a conventional UV-light source combined with a light filter and a coil shaped tube. This way we only use one germicidal wavelength to treat the liquids, and the coil shape creates a turbulent flow that allows us to treat opaque liquids. We can treat both hot and cold liquids, so the process is non-thermal. However, as you know, normally UV-light is not able to kill microorganisms in opaque liquids, so we wanted to give the technology a new name. We wanted a name that explains that this is not a conventional UV system, and it is not a cold process either. So, we have decided to call the technology raslysation.

FE: I see you have two types of systems, the CPS and LTUV, respectively for highly opaque liquids and for low-transparency liquids. What’s the difference?

Mortensen: The CPS, our flagship product, is able to treat any liquid no matter how sensitive the liquid is. That is because it has our specially designed light filter implemented. These light filters sort out all the wavelengths that are not beneficial to our treatment, and thereby ensure the gentlest treatment of liquid products on the market and the best reduction in bacteria, spores, virus and fungi. This is all while still ensuring that the naturally occurring nutrients, vitamins and proteins in the product go unharmed, and thereby can benefit the end consumer.

The LTUV, on the other hand, is meant for liquids that are easier to shine light through, and therefore, can handle larger flows. However, this unit does not incorporate our specially designed light filters since it is meant for liquids that are not sensitive to UV-light, such as process water or brine.

FE: So what are the liquids that can be treated successfully with CPS or LTUV systems? Do these systems kill bacteria, viruses and spores? Are there any noticeable changes to the quality, taste or color of the liquid beverage?

Mortensen: It depends on the product. However, during the treatment, you eradicate any organism containing RNA or DNA, whether it be bacteria, spores, virus or fungi. Because the treatment is so gentle and the energy input into the liquid kept to a minimum, the nutrients, vitamins and proteins in the product are not harmed.

Regarding taste, if we concentrate on raw milk, we have zero changes to the milk when we give a comparable treatment as HTST pasteurization. That means that when we kill as many bacteria as in normal pasteurization we have no effect on taste. However, “the trees do not grow into the skies.” (Ed note: From a German proverb, Bäume wachsen nicht in den Himmel, meaning there are natural limits to improvement.) If we, for example, aim to get the same bacterial reduction as in a UHT treatment, we will get some off-flavors.

“I started the company in my apartment and basically isolated myself for six months designing a commercial prototype.”

—Rasmus Mortensen, CEO, Lyras