Foreign Matter

Detection

Smart strategies for selecting a foreign material detection system

Sharon Spielman, senior editor

Video courtesy of Getty Images/sale013

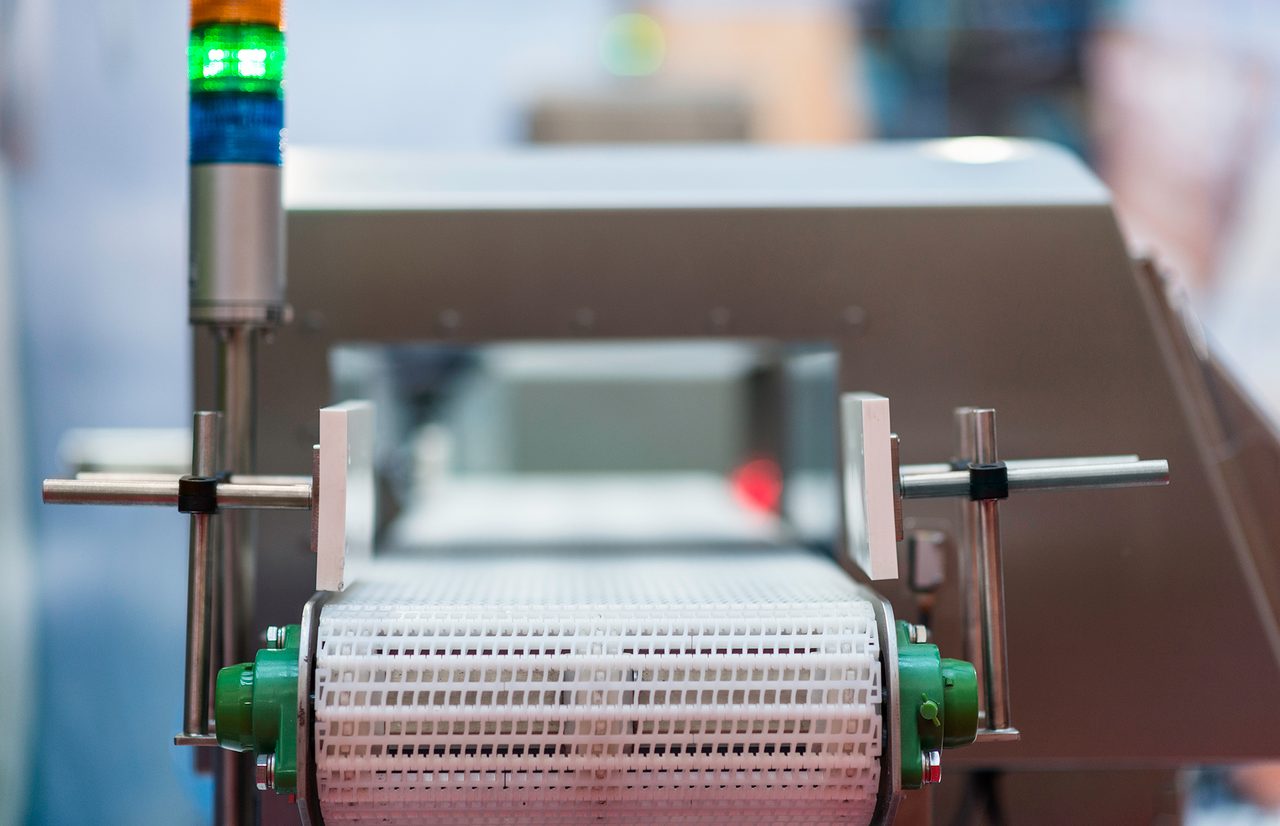

When it comes to foreign material detection in a food facility, different processes require different detection methods and equipment. There are several types of systems that can help detect foreign matter in a food process, among which are metal detectors, X-ray units and magnets.

To understand which method is best for a particular process, the first step is to review the facility’s written foreign material control program and understand how it is being executed. According to Bonnie Biegel, director of quality assurance, Americas, at AIB international, “A strong foreign material control program that adequately assesses risks, puts preventive controls in place to mitigate those risks and is executed correctly by a trained team will minimize physical contaminants in products and reduce the risk of costly product recalls.”

Choosing the best system for a given facility should be based on a hazard analysis, Biegel notes, which will provide an understanding of the risks faced, and direct implementation of the necessary detection systems. “Each system is then most effective when used correctly as part of a food safety plan and overseen by a trained team,” she says.

Barry Voorhees, metal detection product manager at Bunting Magnetics, says that when a company approaches them for foreign matter detection, the first step is to evaluate the process to understand it start to finish. This includes raw material entry points and equipment used, processing equipment from screeners, mixers, conveyors and more. “This is to make sure we have a full understanding of their operation. Then we discuss their concern or problem areas. What CCPs (critical control points) do they have established, and is there any existing equipment for foreign matter removal? Are they currently having any metal issues or is it a preventative measure to improve their protection?”

To understand which method is best for a particular process, the first step is to review the facility's written foreign material control program and understand how it is being executed. Photo courtesy of Getty Images/mediaphotos

Eric Garr, regional sales manager at Fortress Technology, agrees. “The first step we always take is to examine if they already have any specific contamination risks that they need to mitigate. This is then followed with a more comprehensive assessment, looking closely at each step in the production process, the associated contamination risks and then review the feasibility of using an inspection technology at the various steps.” He says that an on-site walk through of their process is generally the best way to identify the feasibility of adding inline detection.

Eric Confer, light industry market manager at Eriez, says that every inquiry they receive starts by asking what the target metal size is. “From there, through a comprehensive needs assessment, we determine what detector and installation is best suited to meet the stated sensitivity objectives.”

Jeff Youngs, president and CEO of ProSpection Solutions, says they will work with a customer’s quality assurance department to review the types of foreign material that have been found in the process previously, or foreign material claims they have received from their customers.

They also review the customer’s process to better understand what foreign objects could make their way into the product stream. “Common culprits include broken conveyor belting, ripped bags and liners, and personal protective equipment (PPE),” he says. “We then perform testing on product provided by the customer to determine what foreign objects our foreign material detection system can reliably detect and report those findings back to the customer.”

An inspection/detection unit at the primary packaging stage can be an effective placement along a processing line. Photo courtesy of Getty Images/agnormark

Whatever detection equipment a company chooses, AIB’s Biegel says those machines will only be as effective as the training they have provided their employees to operate them. “For instance,” she says, “even the best metal detectors can be bypassed by an employee who places rejected product back on the line or turns off the metal detector or reject device when numerous rejects occur. The most important aspect of a foreign material detection policy is to educate employees about the significance of rejected materials and what the device is trying to tell them.”

Detection placement on the line

Where should foreign matter detection systems be placed on the processing line? Should they be at the front where ingredients enter? The end of the process? Before or after packaging?

Biegel notes that to better understand the risks specific to a facility, food safety teams can use hazard analysis, which will help them discover how foreign materials may get into their products. Based on this assessment, they can develop an effective foreign material management plan that includes a series of preventive controls to address and mitigate the risks they found in receiving, throughout the manufacturing process and in packaging.

Guy Wheeler, key accounts manager at Anritsu, says to determine where detection is needed, companies should ask what the potential foreign material is. “If your product is a ground protein, both metal and bone are common issues,” he says. “Ideally, inspecting prior to the initial grind will reduce the amount of bone in finished product. Post-grind inspection for metal shavings would be a logical strategy before packaging.”

Foreign matter detection throughout the production process, especially if any equipment has metal-on-metal contact along the way, is recommended by our experts. Photo courtesy of Getty Images/MJ_Prototype

Bunting’s Voorhees says they recommend detection throughout the process—especially if the process uses any equipment that could have metal on metal contact such as augers, airlocks and hammermills. “If a customer currently has no foreign matter protection, then for brand protection we recommend metal detection at the end of the line either before packaging or after, at the very least.”

He says they then work their way back through the process starting at material ingredient entry points to ensure suppliers are providing clean product and accountability. Any areas where machine protection is critical or potential high wear areas where internal contamination can occur are also good placement.

Garr at Fortress says that end of line inspection after packaging or as close as possible to a fully packaged product is necessary to comply with HACCP and the various global food safety initiatives. “However,” he notes, “that will seldom tell users the original source of the metal contamination. There is always value to be gained from adding upstream detection systems to most processes.”

Incoming materials should be inspected when leaving the supplier, but this may not be guaranteed, Garr points out. “Catching contaminants sooner may mean a single reject of a relatively easy-to-detect contaminant versus a higher number of downstream rejects on packaged finished products. Rejecting at the end of the line is typically the most expensive place to remove the metal from good product streams.”

Factoring in HARPC and recognizing there are specific risks at different steps in the process is a smart approach, Garr says. Detection upstream often makes it easier to detect contaminants, trace to their source and potentially alert staff to equipment failures before they become catastrophic.

Todd Grube, product manager, inspection systems, Heat and Control, agrees that the chance of locating foreign matter increases with each opportunity to inspect the product. However, budget is a key factor in determining which points along the processing line are inspected. “Ideally, at a minimum, inspection at the beginning and end is advised; the beginning so that foreign material from the raw materials is eliminated and is not broken down into harder-to-detect sizes, and the end so that foreign matter from the processing machinery is found and as a final checkpoint before the product enters the marketplace.”

Inspecting ingredients upon receiving allows customers to verify that products are clean as they enter their facility for further processing.

Ray Spurgeon, metal detector product manager at Eriez, says that metal detection should be used throughout the entire process—especially at the beginning. “This is particularly important if blending or other process equipment is used prior to packaging that can fragment one large piece of metal into thousands of smaller pieces.”

Sarrina Crowley, marketing communications manager at Mettler-Toledo, believes that systems should be placed at each CCP throughout the line because “at each stage, value is continuously added to the product, so detection early not only ensures safety but also saves costs and rework.”

Kyle Knudsen, vice president of technology at ProSpection Solutions, says that there are a couple of locations for an inspection system that have distinct advantages for a customer.

“Inspecting product as it is received allows the customer to hold their suppliers accountable for any foreign objects that are detected at that point in the process,” he explains. This also allows the customer to verify that the product is clean as it enters their facility for further processing.

Knudson adds that inspecting product before grinding or any other destructive process is also an optimal time for inspection. This is because foreign objects that undergo a destructive process will break apart, creating more foreign objects that are now smaller and more challenging to detect.

Finally, inspecting product before packaging can ensure that product is clean directly before it is packaged and sealed. “This is also the last point where a thorough inspection of the product for low-density foreign objects can be completed,” Knudson says.