JuLY 2023

PLANT CONSTRUCTION SURVEY Part 1

46th ANNUAL

Plant Construction

survey

Pandemic issues on the wane, but labor, inflation and equipment availability slow projects.

Part 1

AM King designed and built Mission Produce’s avocado ripening and processing facility in Laredo, Texas. Photo courtesy of AM King

If you’ve ever played “Whac-A-Mole” on the boardwalk or at an arcade, you can get a sense of the frustration that both food and beverage processors and architecture/engineering/construction (AEC) firms are feeling in today’s economy—fix one problem, another pops up. Though the effects of the COVID-19 pandemic are sinking from view, the havoc that the pandemic wreaked with the supply chain and the economy is popping up in both expected and unexpected ways. We expected a slow recovery from the pandemic—especially with supply chain issues and the economy, but for some AEC firms, unexpected surprises either slowed projects or opened new projects.

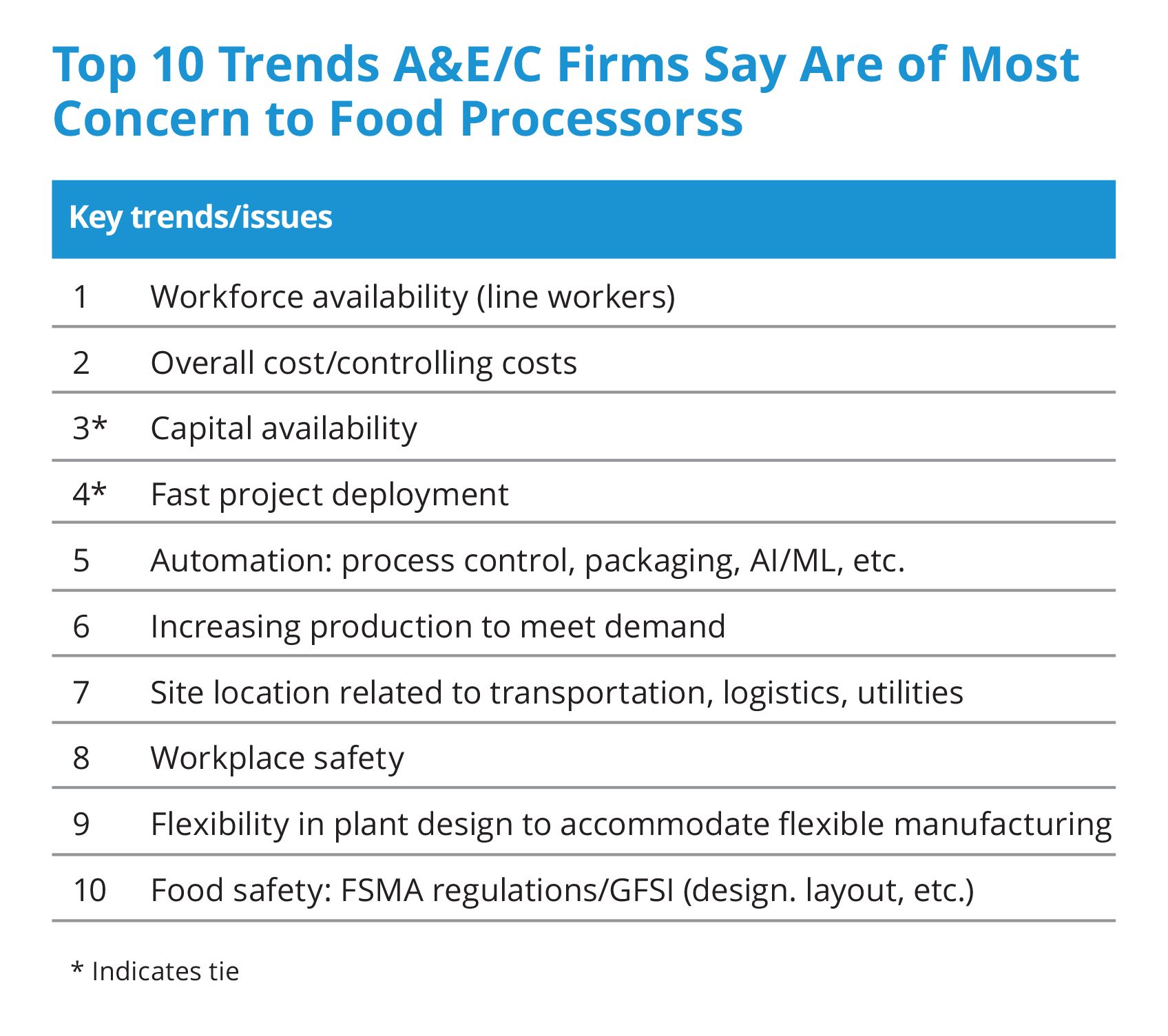

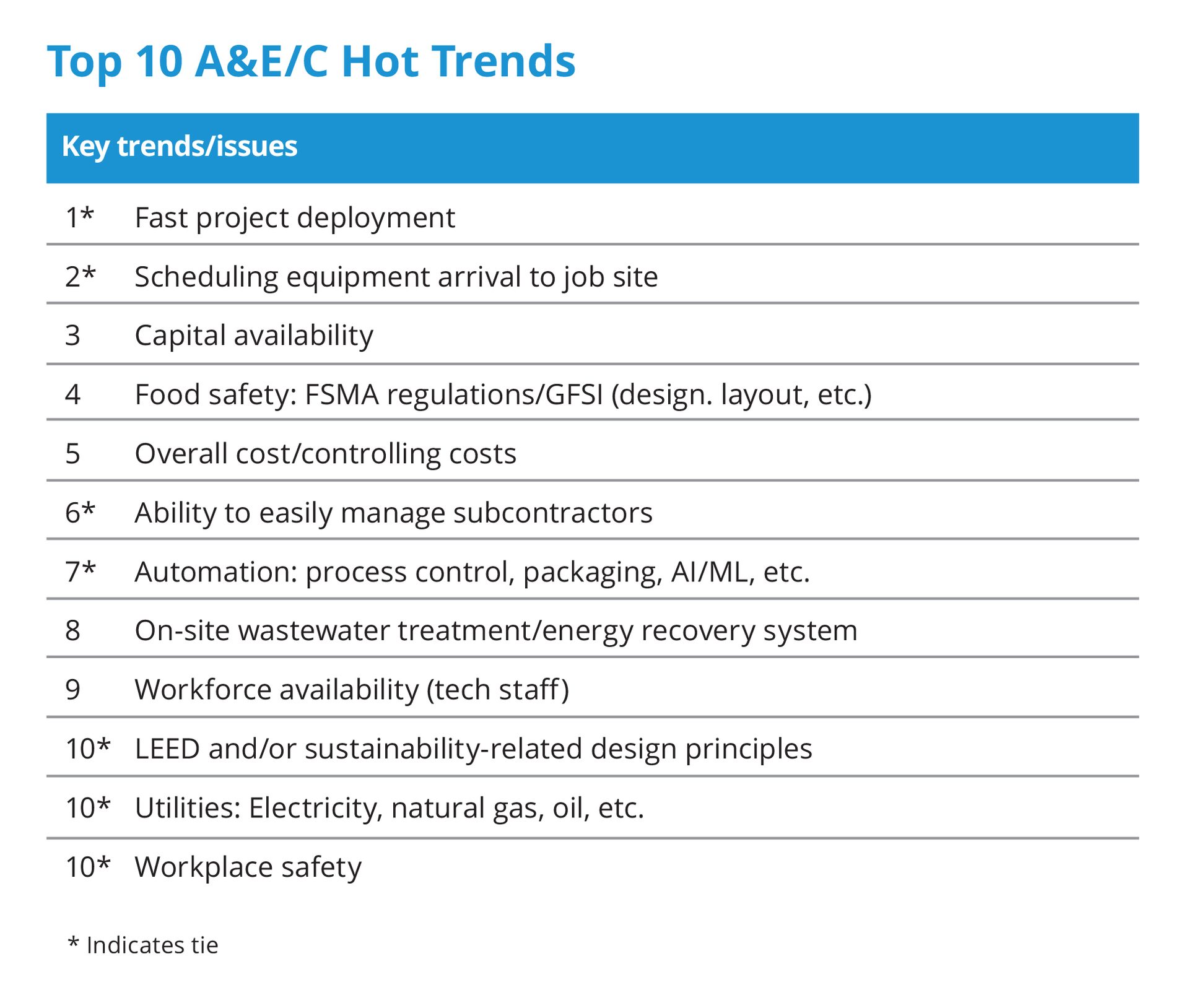

To see what issues are trending this year, we asked A&E/Cs what are the ten hot trends affecting them as they manage projects (see “Top 10 AEC Hot Trends”), and we also asked them to list what they see as the ten issues of most concern to their food and beverage processor clients (see “Top 10 Trends AEC Firms Say Are Of Most Concern to Food Processors”). The first three items on both lists definitely show effects of the pandemic and stagnating economy, and include concerns for capital availability, controlling costs, scheduling equipment for a project and getting projects deployed in a timely manner—and having workers available both for the project itself and to operate a food facility.

Wayne Labs, Senior Technical Editor

Expected Effects of COVID-19 Linger On

“The COVID-19 pandemic is behind us, but the lingering effects still remain,” says Brad Barke, president/founder of ESI Group USA. “Costs and lead times of certain materials have driven building costs to much higher levels. The facility modifications made because of COVID are now more standard with new or renovated facilities. The administration’s attempt to curb inflation has caused owners to rethink new facilities and additions as the fear of inflation and a slowdown in the economy remain very real.”

“The high inflation experienced under the Biden Administration has caused drastic increases to the cost of most goods and services,” says David Sawicki, AM King business unit leader. “These cost escalations and subsequent attempts to control inflation are straining access to capital and making CapEx projects more challenging to get approved.”

“We are seeing projects placed on hold due to looming recession,” says Ronald L. Rens, president, Gleeson Constructors & Engineers, LLC. “Capital projects are decreasing due to lower demand and margins caused by inflated costs and tight supply chains. Owners are delaying projects as they seek funding or grants. Projects are taking much longer to start and durations are extended based on availability of equipment and materials.”

Some food processors are feeling the brunt of our weakened economy. “Elevated inflation has led to decreased unit sales, which in turn have led to decreased production demand overall,” says Tony Moses, CRB fellow, director of product innovation. “So, [food] companies are sizing their facilities accordingly or choosing to delay some projects. With the tight labor markets, we see companies being more deliberate about facility location and the degree of automation. We’re also seeing opportunities with contract manufacturers, as more consumers turn to private labels, and some companies delay investment decisions.” (For site location pointers, see “Site selection criteria.”)

AM King renovated and expanded Daniele Foods’ salami plant Burrillville, R.I. Photo courtesy of AM King

Not all news is entirely negative. Despite the inflation issues, the demand for construction projects in the food and beverage sector is still strong, says Nate Larose, CMC Design-Build director of project development. But he wonders what the next couple of years could bring. “Higher interest rates and concerns about how the overall economy will fare are worrisome to many.” In spite of this, Larose sees an unexpected, brighter side to the situation. The weakening of the economy has led to some softening in the real estate market and in the cost of construction materials, which are helping to offset the higher interest rates.Though costs of construction have risen due to inflation, smaller projects still succeed. “We continue to see an increase in the number of entrepreneurs who approach us wanting to develop small processing plants for local distribution,” says Mark Redmond, president of Food Plant Engineering LLC. “We are frequently approached by meat processors seeking to expand their current operations.”

Site Selection Criteria

Site selection criteria has not changed all that much, but the COVID-19 pandemic and supply chain issues may change some of the ways you think about site selection. Here are some pointers from our A&E/C professionals. This is not an exhaustive list.

• Labor availability (including skilled technical and professional)

• Access to and cost of utilities (natural gas, electricity, water, sewer, etc.)

• Regulations (local/state regarding land usage, water usage, wastewater, wetlands, environmental rules, etc.)

• Will an onsite wastewater pretreatment site be necessary?

• Transportation/logistics (interstate highways, railroad, trucking companies, etc.)

• Incentives (e.g., local government, state government)

• Taxes (Including property, employee occupational, etc.)

• Availability/site readiness (“shovel-ready” with utilities in place)

• General business climate

• Nearness to raw materials/ingredients

• Nearness to markets

• Availability of technical resources (engineering houses, system integrators, etc.)

• Nearness to educational systems (tech schools, colleges, universities)

• Weather (storms, floods, earthquakes, etc.)

• Topography (soil issues, hilly, rocky, etc.)

• Location, location, location: an old real estate axiom)

The Gilbane Alberici Joint Venture has completed several projects at Constellation Brands Nava, Mexico facility. Image courtesy of Alberici Constructors

The Unexpected: Bad and Good

Finding labor has been a problem for some time, but who would have expected that the government’s funding of public projects would create a problem for food and beverage construction? “With the Biden administration’s recent actions to spur spending on infrastructure, biotechnology and biomanufacturing, there is high demand for construction materials and especially labor,” says David Ziskind, Black & Veatch director, food & manufacturing solutions. “Food and beverage clients are taking advantage of opportunities as funding becomes available, but also find themselves in the position of competing against other construction projects for labor. While the Administration’s actions provided for funding, there is still work to do in developing additional construction labor for this demand.”

While U.S. markets seem to be slowing, there may be more activity globally, according to Tyler Cundiff, president, food & beverage group, Gray, Inc. “The last few years have been very active in the food and beverage industry, and we expect an even greater surge in capital spending activity within the global market looking ahead. Many factors contribute to this activity including manufacturing enterprise consolidation, an increased focus on food safety upgrades, innovative new processes and products as well as dynamic and growing global consumer demands. In addition, much of the current new project activity is a result of a drastic disruption to the global food supply and delivery system due to COVID-19.” End of Part 1

JUly 2023