HPP

Changing Consumer Attitudes on Sustainability

For certain high-value products where extended shelf life and preservation of nutrients and vitamins are crucial, HPP offers a bacterial inactivation process that doesn’t interfere with the organoleptic nature of food and beverages.

HPP Systems:

When No Other Bacteria Inactivation Process Will Do

High pressure processing (HPP) isn’t suited to every food or beverage application, but for those special products that need this intervention to inactivate bacteria without affecting taste or other properties, no other technique will do.

While basic HPP technology hasn’t changed all that much over the last few years, capacity keeps increasing, robotics assist in loading and unloading, enhanced automation manages the process and, in some cases, additional thermal process capability widens product reach. Automation software — enabled by AI and machine learning — is smoothing out scheduling bumps, providing accurate processing and determining when maintenance needs to be done so there aren’t any surprise shutdowns.

At the same time, HPP has expanded into new product areas, such as pet food and specialty health products — and the number of tolling centers has increased to help startups and processors who need more capacity during holiday seasons.

Size and Throughput Keep Increasing

Quintus Technologies’ portfolio of HPP presses is available in 150-, 400- and 600-liter capacity, says Keenan Drenning, director of high-pressure processing for the Americas. “The 600-liter machine, launched in 2025, is the largest capacity and most productive HPP press ever built.” Within those model sizes, Quintus allows processors to add high-pressure pumps, which speeds up the pressurization and thereby improves the throughput of the machine. In this way, a user could buy an entry-level machine and add more productivity later with a small upgrade rather than needing another capital equipment investment.

“Using a toller initially is always an option, of course, but our 150L smallest press has a very attractive payback period for initial production volumes,” Drenning adds.

By Wayne Labs

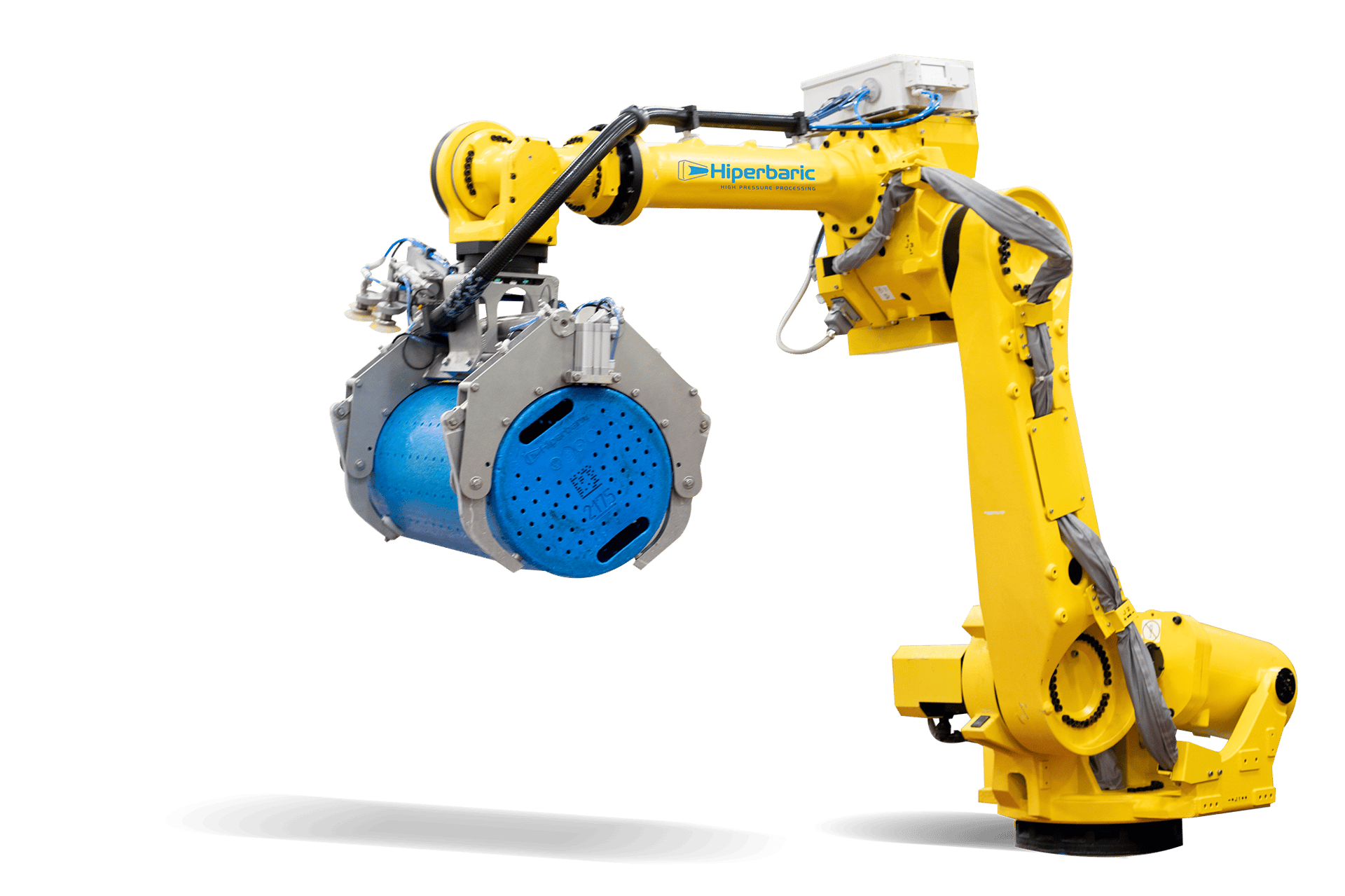

Hiperbaric recently announced the installation of its 400th HPP system worldwide. The milestone installation, a Hiperbaric 525i model, was completed at Instinct’s 150,000-sq.-ft. Nebraska raw pet food facility. The 525-liter system can process approximately 8,030 pounds per hour with a speed of 10.7 cycles per hour. Robots do the heavy lifting, loading and unloading. Credit: Photo courtesy of Hiperbaric

The Quintus Model QIF 600L (600-liter) HPP system was released earlier this year and has a 18.5-in. diameter vessel diameter to improve load efficiency and accommodate more packages per cycle. Equipped with up to 12 intensifiers, the scalable system can process 9,140 lbs. (4,150 kg) per hour to meet demanding production needs. Photo courtesy of Quintus Technologies

Hiperbaric offers a comprehensive range of HPP equipment, with models tailored to meet the needs of academia research and emerging brands to medium and large-scale food processors, says Roberto Peregrina, Hiperbaric – High Pressure Processing executive director. “Our machines range from the compact Hiperbaric 55, which processes up to 800 lbs. per hour, to the high-capacity Hiperbaric 525, capable of handling up to 8,000 lbs. per hour.

“Beyond just size, processing speed is a critical factor for throughput and efficiency — and this is where Hiperbaric excels,” Peregrina adds. “Our machines are engineered for shorter cycle times, maximizing product output and minimizing bottlenecks in production lines.”

ISO, a Miami-based beverage company, recently launched a line of cold-pressed electrolyte beverages. Developed at the Hiperbaric High Pressure Processing (HPP) Incubator, these hydration products combine food science with whole-food ingredients to create a unique drinking experience. Each bottle contains over 700 mg of essential electrolytes to support optimal hydration. Photo courtesy of Hiperbaric

The range of vessel sizes does seem to be an advantage to HPP customers who want to tailor their production needs to HPP equipment, says Dr. Errol Raghubeer, JBT Marel (Avure) VP of microbiology and food science. “However, the primary goal of manufacturers is the product output per cycle. Production output is mainly determined by the time to come up to operating pressure and the diameter of the vessel that is being used. Having a larger vessel does not necessarily mean larger output.

“For example,” says Raghubeer, “if looking at two different vessels with the same size but with two different diameters and the same come-up time to pressure, the vessel with the larger diameter will have a greater output. JBT Marel’s 525-L system has a larger diameter than other 525-L systems, allowing for less dead space (unused space) in the vessel, thereby delivering more product per cycle. Large-capacity vessels will have longer come-up time to pressure, which will increase cycle time. This can be resolved by either using multiple pumping systems (high-pressure intensifiers) or with significant engineering improvement in high-pressure pumping systems, with the latter being available to JBT Marel customers shortly.”

JBT Marel offers a range of commercial HPP equipment:

- The AV10 (100 liters) with a production of 10 million pounds per year using 87,000 psi and a hold time of three minutes,

- AVM upgradable (350 liters)

- AVX upgradable (525 liters)

- AVS vertical system that is used primarily in the seafood industry.

In addition, JBT Marel offers an HPP water filtration system, which helps in the reuse of water without debris. The AVM model is available as an AV-20M, AV-30M and AV-40M by varying the number of pumping systems to meet customer production needs. As production needs increase, users can add pumping systems instead of buying an entirely new HPP system. Similarly, the AVX system is upgradable to meet production needs with Models AV-40X, AV-50X, AV-60X and AV-70X. Production volumes range from 40 million to 70 million lbs. per year operating at 87,000 psi with a hold time of 3 minutes.

While not a robotic system, JBT Marel’s Tilt Basket Unloading system makes loading and unloading of baskets easier than manually doing the work. Photo courtesy of JBT Marel

Tolling Centers a Potential Solution for New Applications

For food and beverage companies entering the HPP space, tolling centers are an excellent way to begin, says Hiperbaric’s Peregrina. These facilities allow processors to gain market traction and better understand demand before committing to equipment. Tollers also play a critical role for established brands looking for additional capacity or market expansion without upfront capital investment.

Tolling operations are important not only for small manufacturers to get into HPP production, but also for larger companies to use HPP technology on many of their product lines without having to change their operation to accommodate installation and operating HPP systems, says JBT Marel’s Raghubeer. Additionally, many companies that own HPP systems also use HPP tollers when seasonal demands for products are high. To gain control of their production, several companies that have used HPP tollers have decided to bring HPP in-house as production needs increase, coupled with a reduction in cost compared to tollers.

“Typically, customers prefer to work with someone local to their processing location, but it depends on their distribution footprint, services offered, etc., so it would need to be considered case by case to find the right solution,” says Quintus’ Drenning. “We are happy to share with any company trying to get into HPP or improve their results.”

“Our tolling partners are strategically located across five continents, with many facilities situated in or near major metropolitan areas known for food production and distribution,” Peregrina adds. In the United States, some of the largest and most-established HPP tollers include Universal Pure, HPP Food Services, American Pasteurization Company and Green Plant. These tollers operate multiple Hiperbaric units across several locations, offering high-volume capacity and rapid turnaround.

“In addition to HPP services, many of these facilities provide value-added solutions, such as co-manufacturing, cold storage, refrigerated transport, labeling, packaging, inventory management and tempering,” Peregrina says. This integrated approach makes tolling providers an efficient, scalable option for both established brands and new market entrants.

Automation Adds to HPP Functionality

Robotics, automation, AI and ML plus predictive maintenance (PdM) are some of the new functionalities added to HPP systems. Quintus has delivered HPP equipment with automated infeed and outfeed robotics, Drenning says. “We have several ready-made concept designs but can also cater to the scope for the customers’ needs… Our machine-learning programs are focused on predictive maintenance and issue resolutions to plan or prevent machine downtime events around production to maximize throughput.”

JBT Marel has worked with a number of companies to provide varying degrees of automation to HPP production from pick-and-place robotics, unloading and basket return systems, Raghubeer says. In addition, JBT Marel offers a Tilt Basket Unloading system. JBT OmniBlu is a digital program that provides parts and service availability by monitoring HPP systems and other critical analytic data, reducing downtime and increasing productivity of the system.

Hiperbaric offers a range of automation functionalities to support high-efficiency operations, Peregrina says. “Our equipment can be configured with automated loading and unloading systems, including robotic arms, conveyors and basket-handling systems — all designed to optimize line performance, reduce manual labor and maintain hygienic standards.”

HPP companies make it easy to move heavy loads into and out of their machine with robotic arms. Photo courtesy of Hiperbaric

In terms of software, Hiperbaric is actively incorporating smart automation tools and data analytics into its control systems. The user interface includes PdM algorithms, cycle optimization and real-time diagnostics that improve timing, throughput and machine uptime.

“Our systems are also Industry 4.0-ready, with remote monitoring capabilities and integration with plant-wide SCADA systems — laying the foundation for future applications of AI and machine learning to further enhance performance, product quality and resource efficiency,” Peregrina adds.

“To date, we have integrated more than 25-plus automation systems,” Peregrina says. Companies include Bay Center Foods (subsidiary of Chick-fil-A), Evolution Fresh, Krusteaz, Lineage Logistics, Cava and HPP Belgium Services. Hiperbaric’s latest installation took place at Instinct Raw Pet Food, featuring a turn-key HPP automation solution with loading and unloading robots and material handling. This is Hiperbaric’s 400th installed HPP system.

Foods and Beverage Types Expand

The growth of HPP is influenced by the expansion of current food and beverage categories, as the market for those products increases across the globe, says JBT Marel’s Raghubeer. However, there are a few new product categories that are gaining traction because of health and safety. These include raw and further processed pet food, primarily because of food safety and regulatory needs for both pets and pet owners.

Coupled with the food safety benefits is the fact that nutritional components remain intact after HPP, Raghubeer adds. After the COVID-19 pandemic, consumers looked at nutrition to improve immunity and their overall health. Since HPP does not affect nutritional components and the taste of food and beverage products, many manufacturers have begun to offer highly concentrated fruit-based beverages with heat-sensitive bioactive compounds to boost immunity, such as polyphenols, carotenoids, vitamins and antioxidants. Compared to thermal treatment, commercial application of HPP has no effects on covalent bonds, so nutrition and taste are largely unaffected. Other newer HPP products in the market are nut-based dips and sauces, baby foods, avocado-based products, grain-based puddings and high-protein soups.

Besides pet food and seafood (raw and RTE), other HPP foods include RTE meals and meal kits, dairy products (including cheese and dips), children’s nutrition — and functional shots with adaptogens, probiotics or superfood blends.

The results have been overwhelmingly positive, says Hiperbaric’s Peregrina. HPP has allowed brands in these categories to extend shelf life significantly while maintaining the nutritional quality, flavor and freshness that consumers expect. In many cases, HPP has enabled companies to eliminate preservatives, support clean-label claims and expand into larger retail and export markets that require extended shelf life and strict food safety standards.

The versatility of HPP is helping companies not only differentiate their offerings, but also scale more efficiently while preserving the integrity of their formulations, Peregrina adds.

Adding Heat to HPP…Really?

OK, this sounds counterintuitive to HPP. This process goes by two names, each with its own acronym. “Combining high pressure processing with moderate temperature — known as High Pressure Thermal Processing (HPTP) — unlocks additional capabilities beyond traditional HPP,” Peregrina says. While conventional HPP is highly effective for acidic and refrigerated products, HPTP is designed to extend the benefits of pressure-based processing to low-acid foods, which typically require more intensive microbial reduction due to the risk of Clostridium botulinum and other pathogens.

“At the core of HPTP is a canister compatible with Hiperbaric HPP machines, invented and patented by CSIRO, the Commonwealth Scientific and Industrial Research Organization, Australia’s national science agency,” Peregrina adds.

Advantages of the HPTP Technique

Advantages of the HPTP Technique

The advantages of combining technologies include:

- Enhanced lethality: HPTP enables the inactivation of more heat-resistant spores and pathogens that wouldn’t be fully addressed by pressure or heat alone.

- Shelf-stable products: HPTP makes it possible to produce shelf-stable foods without preservatives, offering clean-label benefits and ambient storage.

- Retention of quality: Compared to traditional retort or UHT processing, HPTP delivers better flavor, texture and nutritional preservation, thanks to reduced thermal load.

- New product categories: It expands HPP’s reach into low-acid ready meals, soups, purees, baby foods and protein-based products that traditionally relied on heavy thermal processing.

This hybrid approach is ideal for food processors looking to develop safe, high-quality, shelf-stable alternatives to conventional canned or retorted products — without compromising on freshness or label transparency.

Hiperbaric is pioneering this space with HPTP systems, enabling food manufacturers to explore entirely new market opportunities.

— Roberto Peregrina, Hiperbaric

The combined HPP/thermal process is also commonly referred to as Pressure Assisted Thermal Sterilization (PATS), says Quintus’ Drenning. “The U.S. Army tested the viability of this process with several large food companies and academic institutions. Adding heat (121°C or 250°F) allows this to be considered a thermal retort process, which increases effectiveness against bacterial spores. This is important for the effectiveness of HPP for higher-pH foods – products which are otherwise more challenging to treat with HPP alone. Meanwhile, the organoleptic quality of the product is better with HPP plus heat than with traditional higher temperature processing.”

JBT Marel tested the PATS process, funded mainly by the U.S. Army Dual Use Science and Technology (DUST) program with the participation of several large food, pharmaceutical and packaging companies, Raghubeer says. The project was headed by JBT Marel and coordinated by the National Center for Food Safety and Nutrition (NCFST), now IFSH, and the National Food Lab, with guidance and collaboration from the FDA. Both PATS and HPTP are thermal processes where retort temperature (at least 121°C) needs to be achieved over the hold time. PATS required a preheating step, followed by treatment at 121°C. To achieve this temperature, a special HPP was built that reaches at least 7,000 bars (over 100,000 psi) to generate the adiabatic temperature rise with preheating to reach 121°C.

More than six years of research resulted in the FDA granting approval for one product: the mashed potato. Two major PATS issues were accurately measuring temperature distribution in the vessel and the cost of the equipment for operating above 100,000 psi.

Seafood and HPP

HPP is mainly used in the seafood industry for shucking lobsters and oysters, says Quintus’ Drenning. “High-pressure shucking yields higher meat extraction than manual (hand) shucking. All of our HPP presses are versatile for both seafood (mollusk and crustacean) shucking and for pathogen elimination. The Vibrio bacteria is inactivated by HPP at lower pressures than are needed for other microorganisms in different types of food products, which can be achieved in the same cycle as shucking.”

In the shucking process, live bivalves (such as oysters and clams) or crustaceans (like lobsters and crabs) are loaded directly into the HPP machine, says Hiperbaric’s Peregrina. The application of high pressure separates the meat from the adductor muscle, allowing for clean, raw meat separation from the shell.

With HPP applied to seafood, after processing, the meat slips out easily from the shell with less waste than other methods. Photo courtesy of Quintus Technologies

For this application, “Hiperbaric integrates a specialized seafood kit, which includes a filtration system designed to capture shell fragments and organic debris during processing,” Peregrina says. This ensures a cleaner product environment, reduces maintenance needs and helps maintain equipment hygiene and performance.

Other than the shucking applications, a disadvantage of using HPP for seafood products is that several products cannot be sold in the retail market in the U.S. and Canada due to the FDA Seafood HACCP regulations, says JBT Marel’s Raghubeer. The potential risk of toxin production by non-proteolytic Clostridium botulinum strains (Types B, F and E) exists, as these can grow at refrigeration temperature.

The JBT Marel Model AV-S HPP system is specifically designed to handle seafood products. It produces increases in shellfish and crustacean meat separation of up to 80% compared to other meat extraction methods. The unit is capable of producing annually 23.8 million pounds with a three-minute hold and 32.9 million pounds with a one-minute hold. Photo courtesy of JBT Marel

“The disadvantage for HPP with seafood products is that it is a requirement of the FDA seafood HACCP that refrigerated products be packaged in 10,000 OTR films, which will create an oxygen-rich environment (aerobic),” Drenning says.

While an aerobic environment slows Clostridium botulinum growth, it supports the growth of spoilage mechanisms, such as Pseudomonas spp, Shewanella putrefaciens, and molds and yeast, which reduce shelf life and negate the benefits of HPP.

However, some HPP seafood-based wet salads and dips are in the market since pH can be adjusted below 5.0, which prevents the growth and toxin production of these Clostridium botulinum strains, Raghubeer says. To maximize the shelf-life benefits of HPP products, products are usually packaged with the exclusion of oxygen, which favors the growth of anaerobes.

Resources

“Getting Pressure to Remove the Heat?” Food Engineering, Dec. 26, 2023

“Hiperbaric: HPP Tolling,” Web page, accessed 30 April 2025

“JBT: Find an HPP Tolling Center,” Web Page, accessed 30 April 2025

Quintus Technologies (Food Processing) Web page accessed 30 April