The growth of to-go meals is increasing demand opportunities for the self-heating food packaging market. Features include convenient and instant use, time and energy efficiency, and packaging at adequate temperature.

According to Transparency Market Research, the global self-heating food packaging market held $60.35 million in 2019 and is expected to reach $89.16 million by 2027, at a CAGR of 5.0% during the forecast period. Rising need for instant heated food and expansion of the food & beverages industry in Europe are increasing growth. However, as the cost of this type of packaging is higher, it is hampering the growth as well.

TMR analysis reveals that the market share held by the cans segment is high, compared to other packaging types such as bottles and pouches. Furthermore, TMR found that the demand for self-heating food cans is anticipated to rise substantially during 2019-2027. However, the bottles and pouches segment is expected to collectively account for more than 15% of the total market share in the global self-heating food packaging market.

The beverages segment is going to see lucrative growth during the forecast period as consumers choose cans, pouches and bottles for the packaging of liquid products such as soups, tea and coffee.

Packaging for instant-heat soups and warm beverages is getting smarter

Demand for to-go meals leads to growth in self-heating food packaging

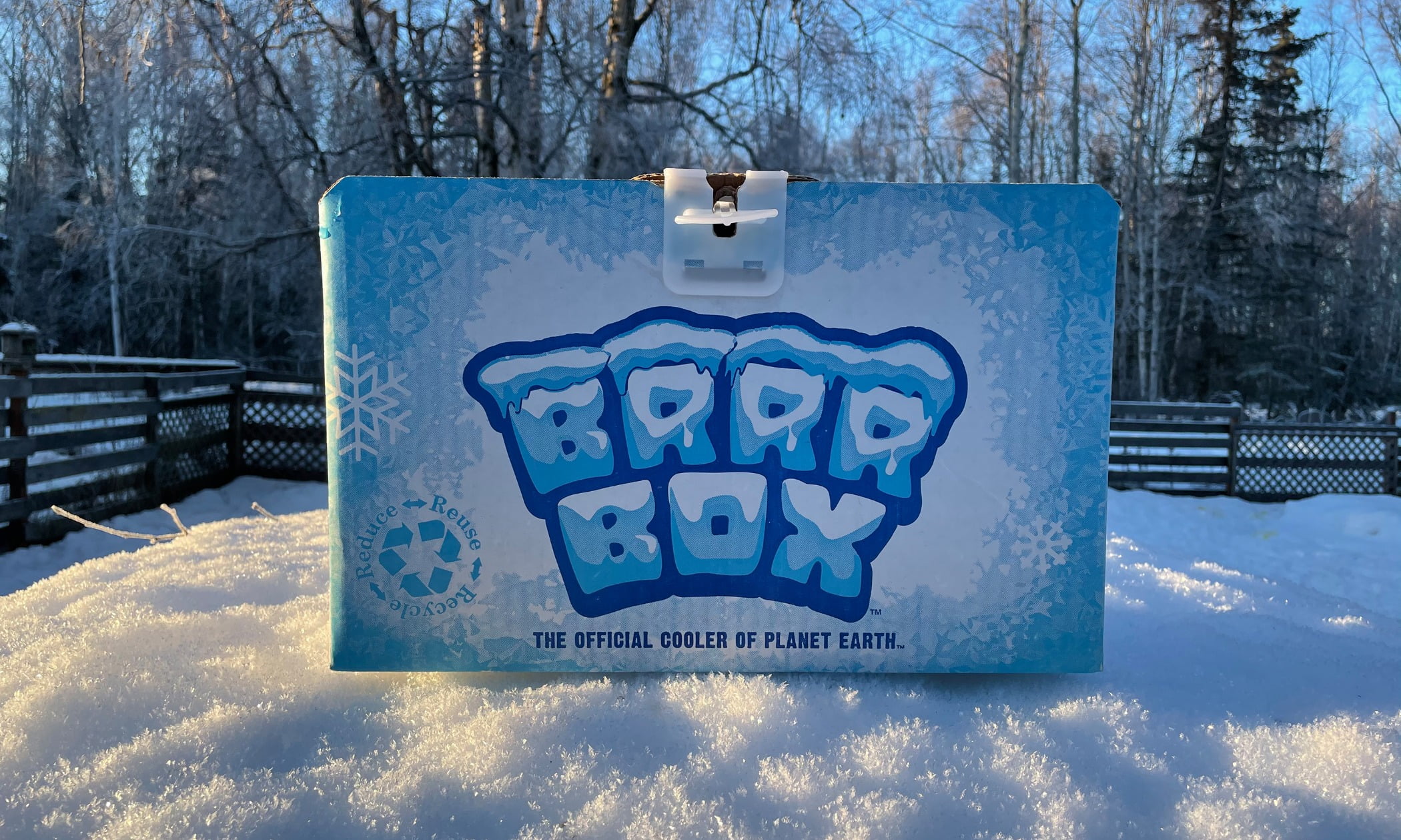

The biodegradable Brrr Box is moisture-resistant and FDA food-contact safe. Photo courtesy of DS Smith

DS Smith has partnered with Vig Pak LLC on Brrr Box, a patented biodegradable cooler. The cooler uses DS Smith’s proprietary Greencoat corrugated moisture-resistant and FDA food contact-safe material to coat this sustainable alternative to Styrofoam.

Greencoat is made of sustainable and renewable fiber that reduces waste to landfills and carbon emissions, unlike traditional plastic foam coolers. Getting behind the new technology is a a major U.S. convenience store chain, says Ed Battle, Brrr Box co-founder and president.

The Greencoat technology uses a patented process applied completely in-house. The technology combines impregnation and coating on the paper to provide durability and long-lasting moisture protection and temperature resistance.

Brrr Box is reusable and holds one dozen 12 oz beverages and 10 pounds of ice—and can keep cold for up to 8 hours. It ships flat and is made in the U.S. The eco-friendly box goes right back into the circular economy and is fully curbside recyclable.

Sustainable alternative puts the chill in beverage cooler

Child-resistant can lock for cannabis beverages

The PakLock child-resistant can lock is made from 100% recycled and recyclable plastic. Photo courtesy of PakTech

PakTech recently launched PakLock, a child-resistant cap designed for THC beverage cans. Made from the 100% recycled and 100% recyclable plastic, like its multipacks, PakLock is designed to be a safe, secure, and simple solution to allow responsible adults to enjoy their THC beverages without children being able to access them.

“As cannabis became more readily available in the recreational market, both in Canada and state by state in the U.S., we started to receive inquiries about whether we had any child-resistant or tamper-evident packaging,” said Lloyd McGriff, director of sales for PakTech. “That was when we realized we could leverage our experience from our PakTech can carriers and meet this new market need.”

PakLock was developed by PakTech’s engineering team and third-party certified meeting the child-resistant criteria set forth by 16 CFR Part 1700.20, PakLock is an important innovation in the growing cannabis beverage market. The lock is easy to apply, fits snug on standard 202-260 aluminum can formats, and is removable by adults.

The can lock is made from 100% recycled HDPE #2 plastic, which means every PakLock is produced from existing recycled plastic. And when you’re done? They’re 100% recyclable as well.

ProAmpac has launched a fully recyclable retort pouch for various foods. Photo courtesy of ProAmpac