some alternatives

Non-traditional pet food:

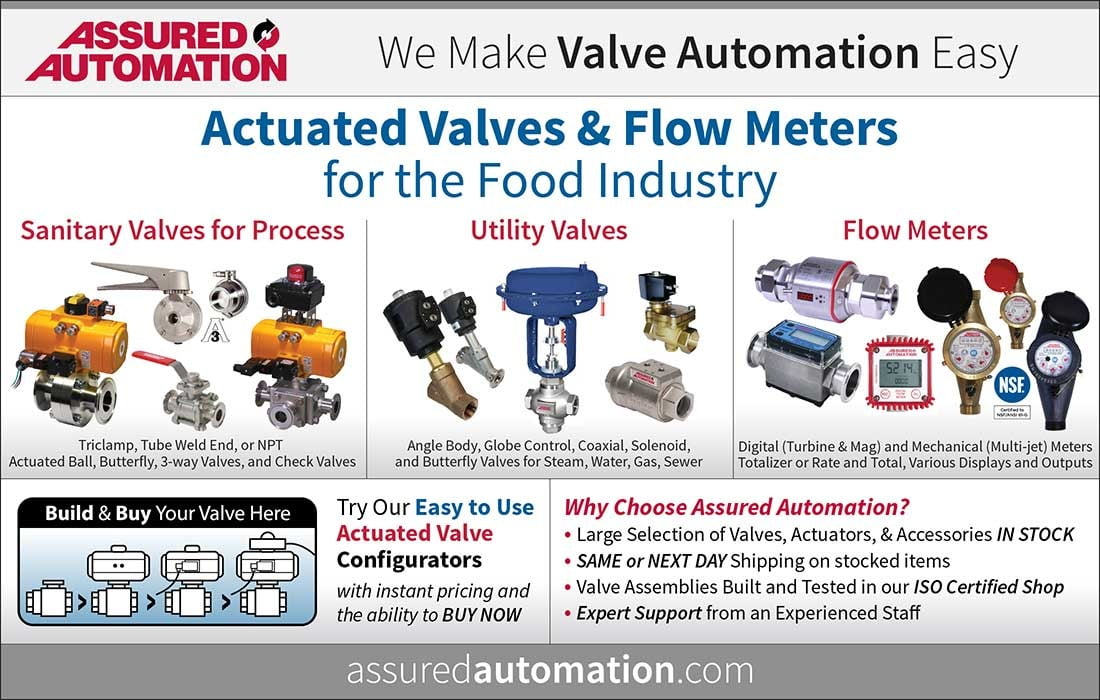

Photo courtesy of Purina

As seen in Food Engineering’s February cover story, “The Rise of Alternative Protein,” the alternative protein market continues to grow. Because pet food trends tend to follow human food trends—much like a puppy or kitten follows its owner—it makes sense that what we feed our pets mirrors what we consume.

Whether Fido’s food is made from all plant-based ingredients, a flexitarian mix of plant- and animal-derived ingredients, insect-based or with lab-grown meat, processors and those who supply the equipment to make non-traditional pet food have their work cut out for them.

Take Switzerland’s Purina Beyond Nature’s Protein brand, for instance. Veterinarians and nutritionists at Purina put together two dry food recipes: one based on chicken, pig’s liver and millet; the second using insect protein, chicken and fava beans. Available for dogs and cats, both recipes hit Switzerland’s retail market in November 2020.

“Every ingredient in our food serves a purpose,” a Purina spokesperson says. “With our new Beyond Nature’s Protein dry pet food, we are offering a complete nutritious alternative to conventional dog and cat products, while diversifying the protein sources.”

When it comes to feeding our pets, processors know that consumers want options for their furry family members. Let’s take a look at a few of those and how they’re made

Sharon Spielman, Senior Editor

Purina says the demand for products made with alternative proteins continues to grow in many food categories, including pet food. This trend is true for insect-based pet food too, which is smaller compared to other sources of proteins like plant-based ones. Purina notes it is also important to consider that pet owners recognize that their pets have a different taste and needs from themselves and therefore, insects may be considered as a more appealing solution for their cats and dogs’ enjoyment, compared to other source of proteins.

Insects, like animal- and plant-based proteins, are good sources of protein, and it is important to blend them to ensure that the product delivers all essential amino acids dogs and cats need. The company says its cat and dog recipes use a combination of protein sources to meet the nutritional needs of different pets.

A couple months after the launch of Beyond Nature’s Protein, the company says it is satisfied with the performance of the range, which was in line with their expectations. They say consumer acceptance is promising. “From a consumer research perspective, we carried out some research in December 2020, and found that 83% of the Swiss consumers who tried the range confirmed their pet liked the product and 75% of them would repurchase the product,” the Purina spokesperson says. The research was conducted among 1,700 Swiss consumers in December 2020.

Veterinarians and nutritionists at Purina put together two dry food recipes for Beyond Nature’s Protein brand: one based on chicken, pig’s liver and millet; the second using insect protein, chicken and fava beans. Photo courtesy of Purina

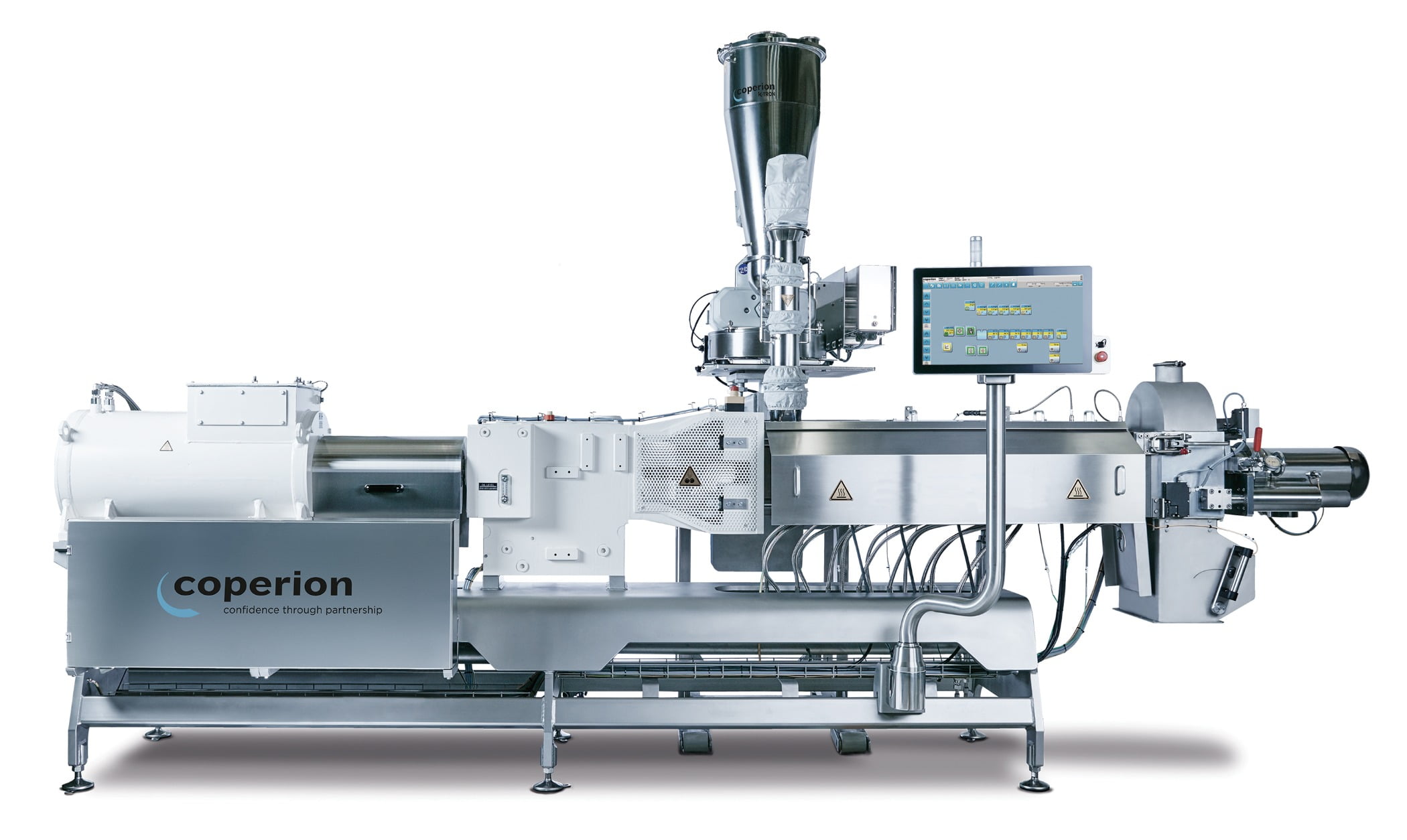

Dry and wet food processing

When it comes to processing plant-based protein in particular, it’s important to note the differences in the extruded products that are often used in pet food, says Sharon Nowak, business development manager, Coperion K-Tron USA. The dry process makes dry texturized vegetable protein (TVP) products used as meat extenders and vegetarian meat substitutes. The wet process makes high-moisture meat analogues (HMMA) with the characteristics of animal meat. There are different processes for each in terms of equipment/lines, process, raw material and processing environment.

Nowak notes that TVP is used both as a meat analogue or vegan meat and as a supplement to meat products. It can be produced in various sizes and forms, as smaller pellets or larger chunks, broken down or ground. TVP is a dry, expanded product with a long shelf life under normal ambient conditions and requires rehydration in water or liquid before use.

HMMA is primarily used as a high-quality meat-analogue product. By adjusting recipe and process parameters, structures of different meat types can be replicated with striking similarity to the original, Nowak says.

Dave Carney, market segment leader at Bühler Aeroglide notes there is a big difference in food safety and handling of the finished products. “Dry pet food kibbles are considered low moisture foods; wet products are high-moisture foods. This is taken into account in every step of the process and plant design.”

Coperion twin screw ZSK extruder offers a hygienic design and is suitable for processing non-traditional pet food. Photo courtesy of Coperion, Stuttgart, Germany

Pet food safety

Processors must be cognizant of what consumers expect—even demand—at all times. “The pet food customer today demands the highest quality product and holds a zero-tolerance policy when it comes to foreign material,” says Lars Povlsen, global sales manager, proteins, at TOMRA Sorting GmbH. “Rubber, plastics, wood and even glass simply do not belong in premium pet food, and an in-line optical sorter ensures a safe and superior product. Investing in optical sorting showcases a pet food processor’s willingness to tackle industry challenges like foreign material and cross-contamination through innovative technology. Processors that implement optical sorting will undoubtedly increase their market share by differentiating themselves from other suppliers.”

Craig Harrison, site manager at JG Pears, a processor of the raw materials for pet food, says the company is delighted with the sorters they installed. “Non-conformances with our customers have reduced dramatically and regarding the TOMRAs, we see very, very little waste and foreign bodies in our material. The current customers already have seen the difference in the finished product, and we're also having lots of interest from additional customers asking and enquiring about buying our material.”

Vicky Prussia, customer relations manager at JG Pears, adds, “After we'd installed TOMRA, we started to look at some of the things that the machine was taking out of our process, and some of the things that we saw were things like plastics, wood, rubber. Just having the TOMRA machines in the factory, we can see now that we are removing more of the foreign bodies.”

Tom Barber, vice president at Bühler Aeroglide, adds that Bühler can assist pet food processors in determining processing parameters for the equipment and formulas incorporating the alternative proteins and non-traditional pet food. “We can do this in our global network of labs and process technology centers that have pilot plants. We can determine the relationship between product formulation, extruder screw configuration and operating conditions, and dryer operating parameters to achieve the desired final product. This would be the same as we do for customers making traditional pet food or pet treats. For truly novel, startup companies with unique product ideas, Bühler has our CUBIC innovation center in Uzwil, Switzerland, for collaboration and development between industry, academia and Bühler specialists,” he says.

Making meat

Speaking of startups with unique product ideas, take a look at the cultured meat segment. Funding for these types of companies was up 266% in 2020, according to FutureBridge, a company that tracks and advises enterprises on the future of industries from a 1- to 25-year perspective.

In the last decade, dozens of startups have sought to make cell-cultured meat both tasty and affordable with the end goal of persuading consumers to turn their backs on conventional meat.

“We are now witnessing cultured meat products move from the lab to the factory,” says Sarah Browner, senior analyst at FutureBridge. “Many cultured meat companies believe they will have commercial products ready within the next few years. However, they caution that it is more important to get the release right than to do it quickly.”

Of course, this data is specific to culturing meat for human consumption. As if on cue, here comes that kitten on its human’s heels. Look at Because Animals, a novel pet food company that began at a cat rescue. Shannon Falconer and her business partner, Joshua Errett, were volunteering to help get stray and feral cats off the street. They wanted to create a healthier, safer, more environmentally friendly way to feed pets, so they used their combined expertise in science and business to create cultured meat for pet food and founded Because Animals.

Falconer notes they are still developing cultured meat, but the process to produce their pet food will be completely vertical. “We can harvest the meat and prepare the food on the same production floor,” she says.

Several people in the industry shared their insights on pet food production and the current role of alternative proteins. Q&As can be found by clicking on the links below. All Q&As have been edited for style, length and clarity. FE