Sharon Nowak is business development manager at Coperion K-Tron USA. The company is a global supplier of feeders, pneumatic conveying components and complete material handling systems, including systems engineering and a global network of field service engineers, parts and training services.

Sharon Nowak, Coperion K-Tron USA

Sharon Spielman, Food Engineering (SS): How is Coperion involved in the processing of non-traditional pet food (i.e., that made with plant-based protein and/or CBD additives, or other non-traditional pet foods)?

Sharon Nowak, Coperion K-Tron USA (SN): Coperion is the international market and technology leader for extrusion systems, feeding technology, bulk material handling systems and services. Coperion designs, develops, manufactures and maintains systems, machines and components for the pet food, food, pharmaceutical and nutraceutical industries.

Because of direct requests from our pet food customers, Coperion has introduced several innovations to our extrusion process product line, which can include all the material handling and conveying of the raw ingredients prior to the mixing step, as well as the extrusion step. Many of these innovations include handling specifically of plant-based proteins as well as CBD additives.

Before we discuss the equipment innovations for PBP, it is important to note the differences in the extruded PBP products, which are often used in pet food productions.

TVP is used both as a meat analogue or vegan meat and as a supplement to meat products. It can be produced in various sizes and forms, as smaller pellets or larger chunks, broken down or ground. TVP is a dry, expanded product with a long shelf life under normal ambient conditions. TVP requires rehydration in water/liquid before use.

When manufacturing TVP, the extruder’s main inlet is continually fed with bulk raw protein material using Coperion K-Tron’s high accuracy loss-in-weight feeders and material handling refill systems. Immediately thereafter, water is injected using Coperion K-Tron liquid feeders. In certain cases, direct steam injection is applied into the process section as well. Within the process section, materials are mixed, kneaded and cooked. The product then moves out of the extruder via a nozzle plate where it is processed such that it achieves a porous, foamy structure with oriented fibers. Coperion ZGF pelletizer’s knife rotor then immediately cuts the product. The TVP granules are then dried to ensure long-term product stability.

Alternatively, HMMA is primarily used as a high-quality meat-analogue product. By adjusting recipe and process parameters, structures of different meat types can be replicated with striking similarity to the original. HMMA’s moisture content lies between approximately 50-80% and must therefore be refrigerated. Protein sources used to manufacture high-quality HMMA are primarily legumes such as soy, lupine or pea. In certain cases, i.e., when manufacturing meat product extenders, lesser quantities of genuine meat or fish products are added.

For the HMMA process, the bulk raw protein material is fed into the extruder inlet. Water is then added. Within the ZSK Food Extruder’s process section, this mass is then fully mixed and kneaded. Discharge takes place using a cooling die that generates a meat-like texture which is “frozen in.” The result is a solid strand with fiber structure similar to meat; the strand is then conveyed to the next process step.

Watch a video of how Coperion has produced HMMA on ZSK extruder in their test lab.

As stated above, in order to address this growing market, not only in pet food but for human food consumption, Coperion has developed several innovations, including:

• Improvements in cooling die technologies, particularly for the high-moisture texturized proteins used in wet and canned pet food products. For example, Coperion has a long-standing relationship with the German Institute of Food Technologies in the development of these technologies for food extrusion. Within this process, the moisture content exceeds 50%, up to 70% in individual cases, which is comparable with the moisture content of lean meat. This high-moisture extrusion cooking process can be used for the production of meat substitutes featuring desirable sensory properties from raw plant materials with high protein content such as wheat, soy, pea and lupine flours protein concentrate. Decisive factors that have been studied through the Coperion/DIL collaboration have resulted in larger scale production size extruders designed specifically for the process of protein denaturation in the extruder, and the control of the downstream cooling and fibrillation in the special cooling die.

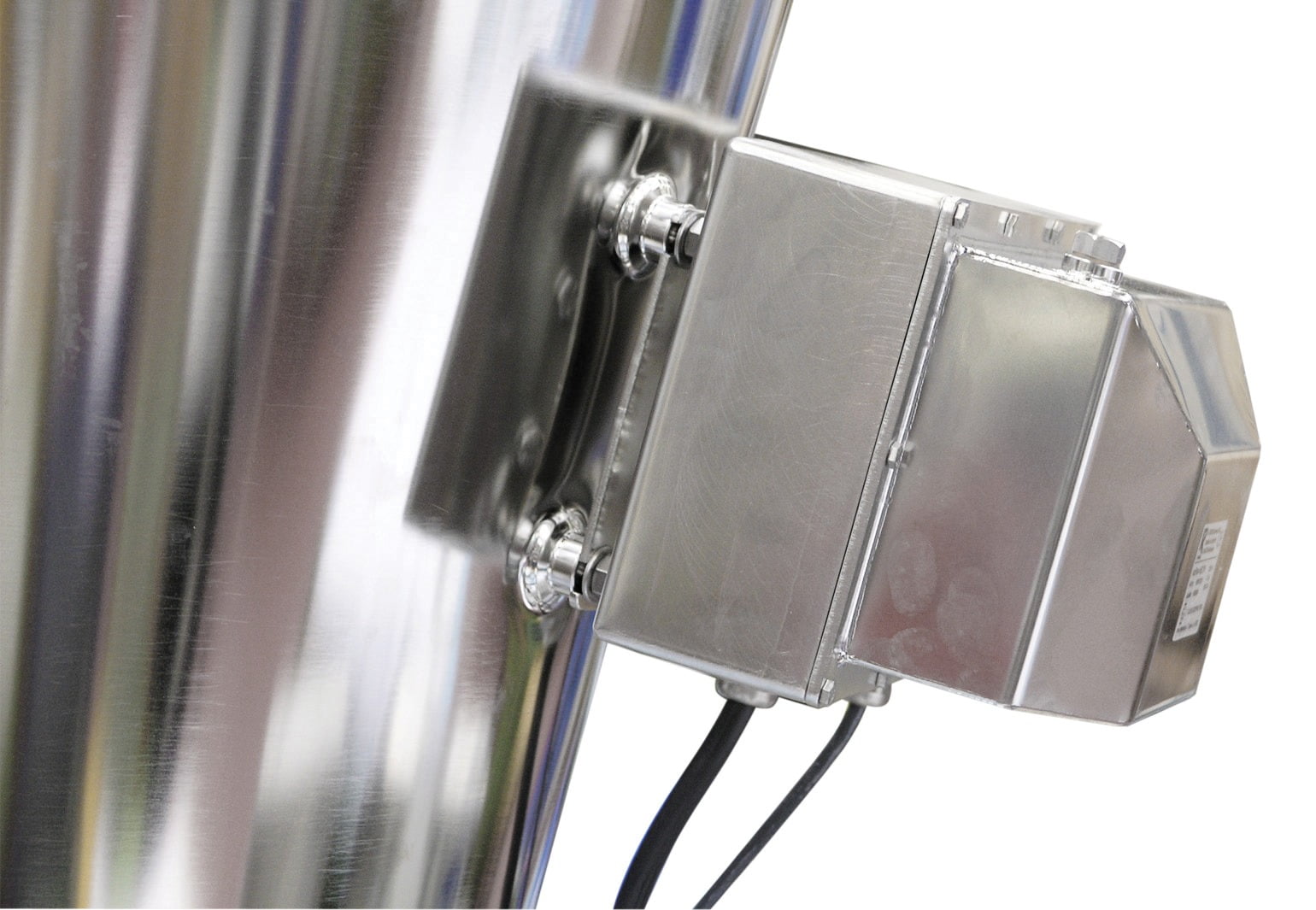

• Improvements in method of feed and feeder technologies of raw ingredients to the extruder. These improvements focus specifically on difficult to feed ingredients, such as many plant based protein powders, which may be very light in bulk density, or cohesive with capabilities to cause bridging in the feeder hopper. For difficult flowing products, the introduction of the Coperion K-Tron ActiFlowTM has been extremely beneficial. This real time vibration device is mounted external to the feeder (with no product contact), but is tied directly into the loss-in-weight signal. If the feeder experiences a bridge or rat-hole and little or no material is being sent to the screws, the ActiFlow vibration is activated and the bridge breaks. After the weight signal is stable again, the vibration is deactivated, preventing additional packing that may sometimes occur with traditional vibration devices. In other words, it is a “smart” real-time vibration device activated clearly by the loss-in-weight signal.

• Dual hybrid design extruder to process both HMMA and TVP in the same extruder. The Coperion Hybrid Design ZSK extruder allows the end-user to develop and manufacture both TVP and HMMA on the same machine with only a minimum amount of retrofitting. The feeding and process section for both applications are nearly identical, while the discharge units differ significantly. While the aforementioned ZGF Centric Pelletizer is attached to the process section for manufacturing TVP in order to cut the product directly at the nozzle plate, HMMA is discharged using the previously discussed specialized cooling nozzle, which produces a product strand that exhibits a texture closely resembling that of genuine meat. Using an adapter solution developed by Coperion, the ZSK Extruder’s discharge can now be switched from a pelletizer to a cooling nozzle in no time. The same principle functions just as quickly in reverse when switching from an HMMA process to TVP.

• Addition of CBD to the Pet Food Extrusion Process. In addition to the TVP and HMMA processes above, as an alternative, incorporating CBD or other oils into the extruded pet food has also been demonstrated. The twin screw extruder’s combination of self-wiping screw design and modular construction allows it to add 10% or more to the extruded product or kibble.

Coperion K-Tron ActiFlow smart bulk solid activator is designed to prevent bridge-building of cohesive bulk materials. Photo courtesy of Coperion, Salina, Kan.

SS: What differences might processors face when making non-traditional pet food vs. traditional?

SN: One of the newest changes to “non-traditional” pet food is the addition of different ingredients. Non-traditional and relatively new nutritional additives can also tend to be more heat and shear sensitive. Extruder settings (e.g. temp, pressure, etc.) need to be adjusted from more traditional pet food kibble applications in order to preserve these ingredients.

In addition, there is also a trend of more natural pet foods, which may include ingredients such as vegetables—e.g., peas, carrots, sweet potatoes, etc. It is important that these ingredients, also known as “inclusions,” be metered into the mixing processes without destroying their shape, texture or composition. Coperion K-Tron’s new loss-in-weight vibratory feeder has proven to be ideal for the highly accurate feeding of these fragile inclusions direct to the process without damage to the product. The innovative patent-pending technology of the new vibratory drive ensures that an accurate mass flow is maintained, without any attrition which may be caused by other means of feeding such as screw feeders. In addition the new vibratory tray design includes a modular quick change feature, ideal for optimizing product changeover as well as cleanability.

SS: What engineering challenges in particular do you see your customers facing when they enter this market space? How are these overcome?

SN: As discussed above, one of the major issues with handling the plant proteins is their cohesive and difficult flowing nature. This can present significant engineering hurdles when designing systems to both convey the powder to the mixer or extruder, and also when feeding the material accurately into the extruder. In addition to the use of the ActiFlow device mentioned above, the internal components of the screw feeder need to be designed to avoid surges, thus twin screws are preferable. For handling the material upstream via pneumatic convey methods, a number of design principles should be adhered to in order to minimize any buildup or flow issues in the transfer and convey lines, such a minimized number of elbows, optimization of the convey tubing and optimized designs of the pickup points and pneumatic receivers, such as the use of aerated hoppers or special easy clean filter assemblies. Finally, the extruder screw design in the feed section needs to be of special design that is not typical for hard to feed materials. In the case of HMMA cooling dies, coatings and liners are very influential in product quality. It is important to note that extruder parameters need adjustment for every new formulation. FE

Intro photo courtesy of Getty Images/humonia