Foreign Materials

Managing

The programs that many food processors adopt to manage foreign materials often focus solely on the equipment that they install to detect and remove foreign materials, especially metals.

Foreign material management is and must be much more than that, however. It includes vendor approval and quality programs, good manufacturing practices, employee guidelines and education, cleaning and sanitizing, glass and brittle plastics, preventive maintenance and pest management. One of the reasons that processors should develop, document, implement and maintain such programs is to help keep foreign materials out of the foods being manufactured. There are several reasons to keep foreign materials out of foods. These include, but are not limited to, the following:

1. Food safety: Protecting consumers from illness or injury.

2. Prevention of adulteration: If a processor knows or suspects a product contains foreign materials, it is deemed adulterated and cannot be sold or must be recalled.

3. Food quality: Foreign material will compromise food quality.

4. Consumer satisfaction: Consumers expect foods to meet their expectations. Finding a foreign object in a food could result in a lost customer; the wrong way to go in a business that relies on repeat sales.

Keeping foreign materials out of foods is essential since the magnets, metal detectors and X-ray machines that processors rely so much on have certain limitations; limitations that will be discussed in greater detail later. They simply do not detect and remove all foreign materials, so it is imperative to keep certain things out of the foods. These include materials such as insects and insect parts; hair; pieces of cloth; wood; and different kinds of packaging materials such as plastics, jute or cardboard. The focus of this piece will not be these preliminary programs that are aimed at keeping things out, but the metal detectors and X-ray machines used to detect and eliminate materials from foods or ingredients during the process flow.

Richard F. Stier, Contributing Editor

Equipment is important, but a foreign materials management program must go beyond that

Photo courtesy of Getty Images / GAnnison

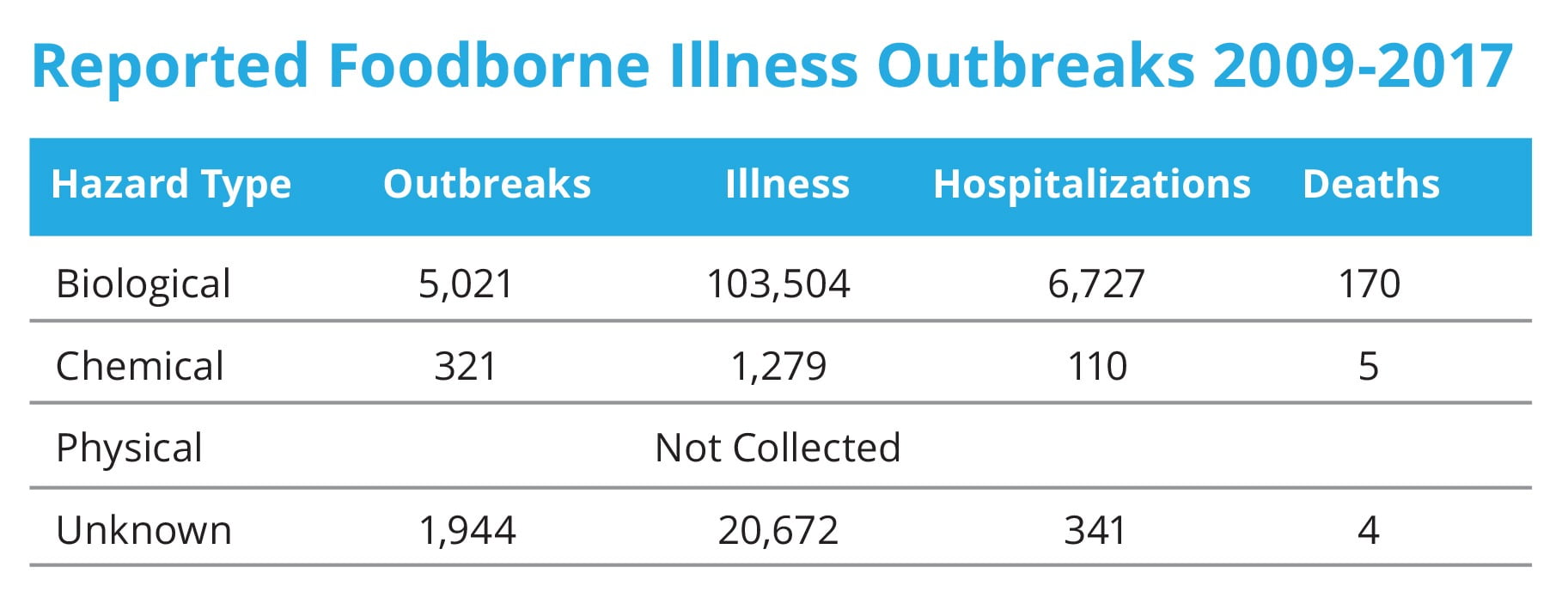

Reported foodborne illness outbreaks between 2009 and 2017 by hazard. Adapted from: CDC Surveillance for Foodborne Disease Outbreaks, United States annual reports, 2009-2010, 2011, 2012, 2013, 2014, 2015, 2016, 2017

Defining hazards

In Section 555.425 – Food – Adulteration involving hard or sharp foreign objects, the FDA has defined what a significant food hazard is:

a. The product contains a hard or sharp foreign object that measures 7 mm to 25 mm, in length.

and

b. The product is ready-to-eat (RTE), or according to instructions or other guidance or requirements, it requires only minimal preparation steps, e.g., heating, that would not eliminate, invalidate or neutralize the hazard prior to consumption.

Samples found to contain foreign objects that meet criteria a. and b., above should be considered adulterated within the meaning of 21 U.S.C. 342(a)(1).

Key Definitions

Sensitivity – The diameter of the smallest sphere (test standard) which is always detected.

Validation – Obtaining evidence that the elements of the HACCP plan are effective. Validation data shall be developed for all critical points/process preventive controls to clearly demonstrate that they are effective for controlling the identified hazard.

Verification – The application of methods, procedures, tests and other evaluations, in addition to monitoring to determine compliance with the HACCP plan.

This document is what most companies use when defining what and when foreign materials may be defined as a significant hazard. It is also referenced in the Hazards Guide the agency has established for seafood (Chapter 20) and for juice. Of course, if the processor suspects that a product contains foreign materials, even if the contaminants are very small, the product should not be sold as it may be adulterated. And, it is illegal to knowingly distribute products that are adulterated. Metal and glass are the most significant hazards that food processors look to manage.

The role of metal detection

Metal detection has become an integral unit operation in many process operations. The 4th Edition of the Seafood Hazards Guide addresses metal inclusion in Chapter 20 and emphasizes the importance of properly calibrating metal detectors based on the type of product, the state of the product (frozen, fresh, etc.) and the type of package. There are similar recommendations in the FDA’s guidance for the juice HACCP regulation.

When setting up a metal detector, the goal will be to ensure that the unit operates at the greatest sensitivity possible. This is done to ensure the greatest protection against metal contamination. With gate type units, a wide range of products may be tested. This includes almost all kinds of foods, including packaged products in non-metallic systems, unpackaged products, frozen products, fresh foods, dry food and even cased items. The gates or apertures should be as small as possible to ensure greater sensitivity. The equipment manufacturer should help the processor select the best unit for the application and help set up the system, which should include initial validation. For a product such as pasta in a cardboard box, the sensitivities might be 1.0 mm for ferrous metals, 1.5 mm for non-ferrous metals and 2.0 mm for stainless steel whereas a case of frozen omelets might be set up with 4.0 mm for ferrous, 4.5 mm for non-ferrous metals and 5.0 mm for stainless steel.

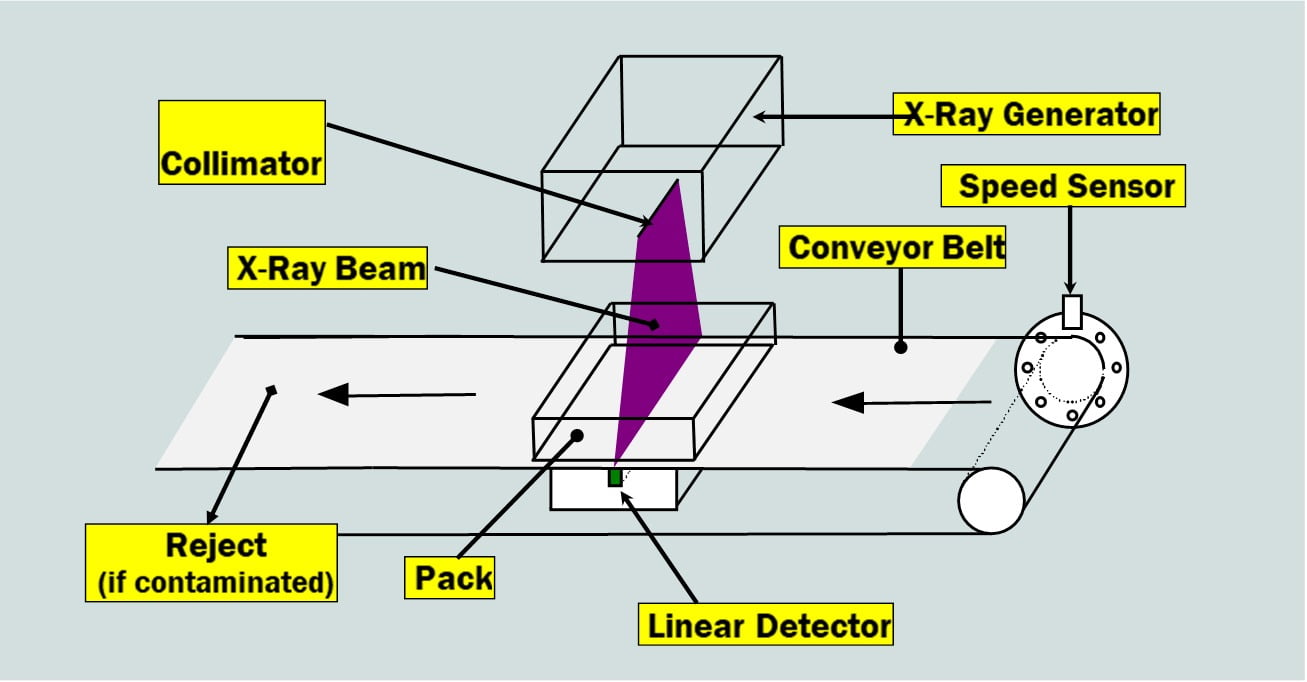

A typical X-ray system setup. Chart courtesy of Thermo Fisher Scientific

Processors should understand potential issues with their metal detector and the products that they are manufacturing. As an example, may processors package products in fiberboard cartons (noodles, rice, pasta) that have been manufactured from recycled cardboard. Occasionally the recycled packaging contains metal fragments which will be kicked out by the detector, yet when the processor looks at the product itself, they find nothing. The investigation to find and identify the metal must, therefore, look at the package and product.

According to Eric Confer, market manager, light industrial, Eriez, the following steps help guide clients into the appropriate detection system by taking into account several factors. They are:

"a. What are the goals of the detection system at the point of use? Some examples would be, are we protecting downstream equipment or minimizing the potential of product liability with finished packaged goods? The goals of the client’s process are truly the most important.

b. How is the product(s) currently being processed? We try to offer a detector that naturally integrates into their process without causing new problems like bottlenecks or maintenance challenges.

c. Ideally, when we specify a piece of equipment, we test the product(s) on a similar or identical system in our central test lab. This allows us to get a “closer to production” sensitivity validation for the client. We then engage with the client to discuss the performance of the metal detector and what they would expect upon receiving their metal detector.

d. More than anything, we focus on giving the client the confidence and quality information necessary to make such a large purchase. Couple that with service and support after the sale, and we can ensure the client will have a reliable system with the best possible sensitivities for years to come."

Metal detectors operate continuously, that is, each and every product on the line will pass through the unit. The processor must establish a program to verify that the system is working. At a minimum, processors should run their test standards through the unit as the start of each production run, in the middle of the run and at the end of the run. In reality, most processors will run the test standards at the beginning and end of each run and at intervals in between ranging from one to two hours.

What to consider when purchasing an X-ray system

All processors needs to take a long look at their operations to determine what their needs are when it comes to foreign material management. Do they need metal detectors, X-ray systems, magnets or some other system? One of the tools that should be used during the decision-making process is company history. Take a look at what kind of materials have been found in the past. Hopefully, the quality group and customer service have compiled such records. Part of the equation should also be the market. Are you selling to Costco or others who “suggest” that X-ray detection be considered?

Thermo Fisher Scientific has compiled a list of 10 factors that should be considered when selecting an X-ray system. Some of these same considerations may also be utilized if one is looking at metal detectors.

1. Meets Safety Standards: The systems must be able to operate safely and meet the safety requirements of any government agency in which the units are operating.

2. Maintenance Schedules: Potential users must incorporate the required maintenance programs into their existing Maintenance Management programs. Maintenance for all components of the system including belts, air filters, and shielding is necessary and must be scheduled at intervals of between 6 and 12 months. As X-ray systems are part of the Food Safety Management System (FSMS), the HACCP or Food Safety Team should have input into maintenance and calibration.

3. Sufficient X-ray Power and Beam Size: The X-ray detection system that a processor selects must have enough power and sufficient beam width to ensure that all products are fully scanned and the potential for false positives is minimized.

4. Sophisticated, Easy to Use Software: Software must be easy to use and be designed to detect a variety of sizes and shapes. Processors have the option of linking their systems to the manufacturer allowing for remote access and troubleshooting.

5. Positioning Flexibility/Validation: When testing a new item or items in the X-ray system, make sure that multiple packages are run with the target standard in different locations within the package. In addition, make sure that the packages are located at different positions on the belt to properly challenge the system.

6. Training: The processor must understand the education and training required to properly set up, operate and maintain the detector. This includes but is not limited to principles of operation, calibration, set-up, safe operation and evaluation of rejects.

7. Component Lifetime: X-ray generation systems and detectors have finite lives. Look for systems that provide a warning when these components are nearing the end of their operational life so they can be replaced thus, ensuring continued efficient operation.

8. Clear Visuals: Select an X-ray detector with a screen that provides clear visual projections of the product and contaminants. Maintaining these images enhances recordkeeping, future training and education, and system maintenance and fine-tuning.

9. Low Total Cost of Ownership: Examine long-term costs of the X-ray detection system, that is, 5-10 years into the future. This includes not just cost and installation, but maintenance, repairs and replacement parts.

10. Reputable Vendor: Work with reputable vendors. Apply the same rigor as one utilizes when selecting suppliers for packaging, ingredients and raw materials. Look at their experience and history with the technology, the customer service package and availability. If possible, talk with other users of that company’s technology.

X-ray detection

The use of X-ray detection has increased throughout the industry. The driving forces have been improving technology, enhance line speeds and reduced costs. In addition, more processors are interested in being able to detect foreign materials other than metals. X-ray detectors may be used to eliminate glass, stones, hard plastics, and other materials since the technology operates on the basic principle of density differentials. Lastly, X-ray detection technology can be used for metallized packaging such as boil-in-bag products and foil wrapped items. And, X-ray inspection systems have other capabilities. They can be used to conform fill levels, monitor seal integrity, mass analysis and can detect missing product.

It is not, however, a panacea. Products like breakfast bars or candies with large inclusions such as almonds or peanuts require special attention.

“The density of nut inclusions in bars is lower than that of the contaminants that are usually being inspected for, so in general, with the right set of inspection algorithms, nut inclusions can be ignored and a successful inspection made,” says Mike Munnelly, field manager, Thermo Fisher Scientific. “That being said, the application can be challenging because the position of the nuts in the bar is random so comparing with a known good image is not possible. If there is any doubt, then the best way to determine how an X-ray system will perform on a particular application is to work with an inspection equipment vendor to perform a product test using actual production samples with the X-ray system of interest.”

In addition, there are foreign objects that will not be detectable due to lack of density differentials. These include pits from cherries, apricots and pears and un-calcified bone such as may be found in immature chickens or fish fillets. Processors interested in adopting an X-ray detection system should also check on local regulatory or environmental regulations. One California processor installed an X-ray detection system for boil-in-bag products in a foil laminate packaging and was informed by local authorities that it needed a special permit for the “nuclear device.”

Munnelly also notes that large, bulky products can be a challenge for X-ray systems.

“Products that are very large and bulky can be a challenge for X-ray,” says Munnelly. “A large X-ray aperture and a high-powered source would be necessary for inspection, which quickly can become impractical due to cost, size, etc. Metal detectors on the other hand are easier to scale-up in size, and a great fit for large unprocessed foods such as those at the very beginning of the processing line.”

Many buyers are now encouraging their suppliers to adopt X-ray inspection technology. Costco’s guidance for suppliers includes the following statement:

Foreign material detection devices, such as X-ray and metal detectors, are an important final step to ensuring that product which has been manufactured under appropriate controls is free of physical contaminants. If you are considering purchasing a foreign material detection device, Costco would like you to weigh the benefits of X-ray over metal detection for your facility. X-ray can not only pick out metal, but also is able to determine densities of rubber, plastic, bone fragments along with sticks or twigs.

Processors should validate the unit for each product as described for the metal detectors and establish a schedule to verify that the system is working. Test standards for X-ray detectors include metals, glass or silica, bone and hard plastics. Sensitivity depends upon the type of unit.

X-ray systems may also be employed to detect and eliminate potential contamination in finished products. Processors can rent or lease a system or send a suspect lot for X-ray scanning to third parties. One processor with whom I worked found that their filler was missing a gasket at the end of a production run. They assumed it was in the product but could not find it through inspection. They leased an X-ray detection system and ran the suspect product through with the help of the contractor. They discovered all the pieces of the gasket and were able to release the lot.

Most processors focus their Food Safety Management Systems on the biological hazards, but one cannot ignore physical hazards.