May 2022

Labeling’s new normal

Labeling considerations have become a necessity after recent supply chain disruptions

Labels—the space where information about a brand, nutritional information, certifications, bar code, the product’s story and more is shared with consumers. With hundreds of SKUs on products, labels need to stand out. Labels can bring results with marketing and promotions tied to them. It tends to be the best way to encourage potential buyers and build trust on the product to purchase it.

So what should manufacturers and brands look for to help them sell their product and build trust with consumers in addition to making sure the process runs smoothly? Following are labeling solutions to offer some guidance.

Space in the cloud

During the pandemic, every step of the supply chain came into the spotlight and labeling was viewed as a vital role. As a result, cloud-based labeling solutions were on the radar of organizations that needed to shift production and accommodate a remote workforce.

Many companies are now incorporating the cloud for this step in packaging, which allows for improved scalability, configurability, standardization and reliability. Cloud is becoming a mainstay for labeling solutions, reveals the annual Top Trends survey by Loftware, the largest global software company specializing in Enterprise Labeling and Artwork Management solutions. The survey was based on nearly 1,000 professionals from organizations across all industries and 55 countries.

Kristen Kazarian, managing editor

UPM Raflatac created labels from 100% recycled fibers. Photo courtesy of UPM Raflatac

Many companies cannot afford to overlook technology to streamline their labeling initiatives. Photo courtesy of Loftware

Almost three quarters (73%) of companies believe the cloud will be the preferred method for labeling applications within the next three years, according to Loftware. This compares to just 50% of respondents reporting their company’s likelihood of adopting a cloud-based solution one year ago. Here are the resulting labeling trends from that survey:

Cloud-based labeling

Labeling has steadily moved into the cloud over the last 10 years, with the cloud now reigning as the mainstay when it comes to software delivery. Labeling has taken on an increasingly important role as companies recognize the direct connection between labeling and supply chain health.

Now, businesses are reaping the results of their cloud-first strategies in the form of removing IT burden, offering continuous uptime and availability, making label changes faster, automating workflows, eliminating errors, and offering financial predictability.

The pandemic and the shifting marketplace have forced companies to think differently about the cloud. This has been due to scarcity of IT resources, difficulty in hiring and new hybrid remote working models along with subsequent supply chain and business disruptions. These shifts have resulted in an accelerated move to the cloud across the broader business landscape.

Simply scanning a label enables companies to obtain vast amounts of information about the product and its journey through the supply chain. Photo courtesy of Loftware

With the cloud, companies can better serve their customers by working remotely and securely at a reduced cost while also creating the opportunity to earn recurring revenue.

Labeling unifies coding & marking

Printing at the plant and production level is a core focus for many businesses today. Although, many companies still do not have software to control the print process for coding and marking devices, which are used to enable direct application on all types of substrates, from a bag of chips to a bottle of water to cardboard box. This is why companies are beginning to think more broadly about their labeling and how to automate printing across production lines irrespective of brand or technology.

Labeling customers not only want orders faster than ever, but those orders must also be accurate, personalized and customized to specific needs. And, evolution of the market has resulted in a demand for more products, shorter production runs, faster turnaround and increased customer requirements. It doesn’t stop there, with demand to print on anything from a smooth card to a flexible or hard plastic, to a curved surface, to a board or even wood.

Coding and marking can offer savings, eliminating the cost of labels and pre-printed inventory. It also can help companies manufacture and package goods with a higher level of authenticity. Businesses are looking for a modern solution with intuitive user interfaces where they can control every print device no matter what the requirements. They want one user experience for designing and printing across production lines, warehouses, suppliers and distribution—all the way across the supply chain.

Consumers are looking for specifics on labels. Forget those, and the system you use won’t matter to your ROI and shopper loyalty. Photo courtesy of Getty Images/monkeybusinessimages

Labeling holds a key to business growth

One thing that has become clear this past year is that companies must be thinking about labeling in step with supply chain strategy. Labeling is no longer a tactical necessity but rather an enabler for business and supply chain operations. Using a cloud-based solution, companies can make a measurable difference and realize significant ROI, which can meet their full scope of labeling and packaging artwork requirements.

This type of solution eliminates multiple steps and redundancies and enables companies to bring product to market quickly, efficiently and more competitively. This streamlined approach enables companies to address common requirements, as well as a host of content and labeling challenges while reducing overlap and costs. When companies deploy a single, more holistic approach, they can centrally source and manage content, label formats, approval processes and workflows. This guarantees accuracy and consistency, mitigates risk, increases agility, optimizes costs and enables global expansion. This of course has become even more important as companies look to launch and move products faster while complying with regional and regulatory requirements.

As requirements increase, companies must find efficient ways to showcase unique data attributes and formatting standards including pictograms, regional requirements, and a vast array of other regulatory content. Also, data elements must appear in specific locations, and new standards dictate which languages need to be applied to labels, based on where goods are traveling though the supply chain.

Implementing a cloud-based solution allows companies to integrate with sources of truth, access centralized data and use business logic to address requirements so they can more easily manage regulatory variations. This approach minimizes the risk of errors leading to costly recalls and fines and helps companies meet requirements with increased speed and agility.

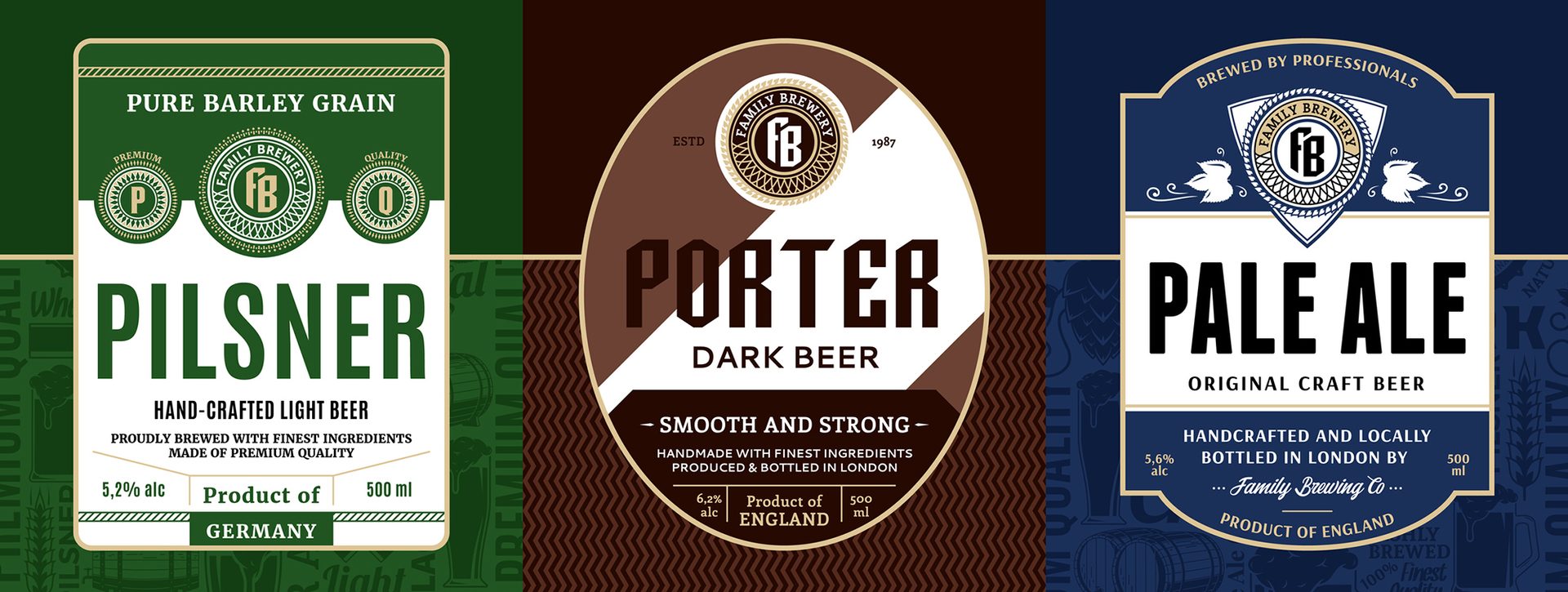

Differentiating labels in a range provides an opportunity to give consumers an easy way to discern different products. Photo courtesy of Getty Images/Vladislav Klok

The focus on digital transformation accelerates

Digital transformation is vital for companies to respond to new risks, shift their business models, and leverage new opportunities using current resources. No longer a luxury, these transformations became crucial during the pandemic and are expected to prevail as organizations emerge from those challenges and plan for what’s ahead. Whether they’re supporting remote workforces, striving for better collaboration across the enterprise or working to improve the customer experience, companies are implementing comprehensive, cloud-based labeling solutions that help them meet these and other goals.

Companies are demanding all-in-one digital ecosystems that are available in the cloud around the clock. By offering a key resource for curating digital information and converting it into a physical representation, labeling stands at the forefront of the digital transformation. Simply scanning a label enables companies to obtain vast amounts of information about the product and its journey through the supply chain. Ultimately, companies that take on this digital mindset can reap the benefits of a streamlined business and intelligent supply chains to become more flexible and deliver results while staying relevant in this shifting global landscape.

Automating labeling artwork processes is becoming more prevalent in today’s fast moving global business landscape. This is because manual processes represent barriers to growth and scale and risk to the business. However, once digitized, manual processes give way to the seamless exchange of data and allow companies to maintain existing systems and user interactions to improve overall efficiencies.

COVID’s lasting impact

The modern supply chain is more complex than ever, with those complexities exacerbated by the global pandemic and subsequent supply chain disruptions. Issues like labor constraints, port congestion, driver shortages and raw material outages—to name just a few, are some of the key pain points companies dealt with in 2021. These will either continue or morph into new challenges in 2022. While many thought the situation would resolve by now, several industries are still having to change operations to cope with changes.

Enterprise Labeling solution can help organizations navigate these changes and futureproof their operations for the long haul. For example, when manufacturers adopt labeling ecosystems that extend across their end-to-end operations, they can readily address any regulatory nuances, maintain strict controls, and ensure continuous operations providing a competitive edge in this new era and in any business conditions. With a renewed appreciation of the supply chain and the role it plays in stocking grocery store shelves, fulfilling B2B orders and a myriad of other activities, businesses and consumers have their eyes on these critical networks.

Behind the process

Moving to a cloud-based enterprise solution is one way to incorporate an overall business solution. However, don’t forget about the label itself. Consumers are looking for specifics on labels. Forget those, and the system you use won’t matter to your ROI and shopper loyalty. Here are a few types of labels to consider to bring your packaging up to consumer code:

Sustainable labels

Hand in hand with packaging comes labeling. Packaging sustainability is a top factor for consumers, so the label should be eco-friendly as well. After all, how good is a sustainable package if the label isn’t environmentally sound as well?

UPM Raflatac introduced last year a full range of paper label products made with 100% recycled fibers designed for food, retail and logistics labeling needs. The range includes the first commercially available Total Phenol Free thermal paper labels made with 100% recycled fibers.

The Consorzio del Parmigiano Reggiano and two partners launched a line of food-safe traceability digital labels for its Parmigiano Reggiano cheese wheels. Photo courtesy of Consorzio del Parmigiano Reggiano

Clean labels

Clean label means uncomplicated, transparent labeling that allows the consumer to know exactly what is in their food or beverage, and where it came from. The trend refers to food products containing natural, familiar, simple ingredients that are easy to recognize, understand and pronounce, with no artificial ingredients or synthetic chemicals.

Labeling that is clean and transparent is a must for packaging. The more open a brand is about their product and story, the more apt it is to find a loyal customer base.

Along with clean labeling comes transparency. Being transparent means being honest about the food supply chain and all the ingredients used in your products, whether they qualify as “clean” or not.

Smart labels

Smart labels are here to stay, and getting craftier all the time. Just recently, the Consorzio del Parmigiano Reggiano partnered with Kaasmerk Matec and p-Chip Corporation to launch a line of food-safe and secure traceability digital labels for its Parmigiano Reggiano cheese wheels. The new technology will deliver previously unseen levels of traceability, inventory tracking and control, product authentication, quality-assurance testing, product serialization and consumer safety.

The p-Chip micro transponders are embedded into 2D codes, QR codes and/or data-matrix codes. The result is an innovative, food-safe digital tag that takes CFPR's food safety and security a step beyond the government requirement.

Remember, nothing goes anywhere without a proper label. FE

may 2022