Cleaning part 1

Changing Consumer Attitudes on Sustainability

There are several cleaning and sanitation methods — each with their own unique capabilities. Combining methods with a plan in place can help ensure that products are safe and the facility and its equipment are free of foodborne bacteria.

Fighting the Foodborne Bacteria War with

Cleaning and Sanitation

Salmonella, E. coli O157:H7 and Listeria monocytogenes (Lm) are three of the most common food-related bacteria that processors have to control. While all three are relatively easy to control through the cooking process, once a product, such as meat, is cooked and used as an ingredient, environmental Lm (on equipment harborage sites, walls and drains) can be a concern in RTE processing and packaging because it survives and does well at temperatures from -0.4°C to 45°C (31°F to 113°F), with 37°C (98.6°F) being an optimum temperature. Not only that, but Lm is also able to survive at a relatively low water activity (aW < 0.90) and a broad pH range between 4.6 and 9.5, as well as tolerate salt conditions up to 20%. And Lm loves to build up a biofilm to protect itself in cracks and crevices in machines and floor drains, making it difficult to inactivate and remove. Boar’s Head recently closed a facility due to Lm infestation.

Lm’s survivability and motility make cleaning and sanitation practices a challenge for any food facility. USDA’s FSIS found meat and fat residue from the previous day’s production on processing and packaging equipment at Boar’s Head, providing an excellent environment for biofilms to form. Other discoveries included condensation from cooling equipment on RTE product and several structural issues that could hold moisture and contribute to wet conditions — the environment that Lm loves.

This article looks at effective methods of cleaning and sanitation (C&S) that can be employed to kill bacteria and prevent pathogen buildup, especially Lm. Several methods can be applied, depending on specific applications.

Photo courtesy: Novolyze

By Wayne Labs

Condensation from cooling equipment, such as evaporators, whose condensate collection trays’ outlets have clogged, causing water to spill out into the cold room and possibly falling on product, is a potential cause of Lm product contamination — such as in the Boar’s Head facility. Photo courtesy of Ross Van Pelt, RVP Photography

Can “Green” Do the Job?

“Green” chemicals, such as plant-derived essential oils and biodegradable surfactants, are increasingly adopted in the food industry due to their environmental benefits, says Karim-Franck Khinouche, Novolyze founder and CEO. While these alternatives can be effective against certain pathogens, their efficacy against resilient bacteria, like Lm, may vary. In scenarios where Lm is present or biofilms have formed, traditional chemicals, like peracetic acid or sodium hydroxide (NaOH), are often more reliable. For challenging sanitation tasks, selecting appropriate traditional chemicals is crucial.

“Whatever chemical is ultimately found to be effective for a particular application, quickly and proactively addressing future contamination requires trusted and comprehensive documentation of not only the effective chemical, but also the sanitation process used in its control,” Khinouche adds.

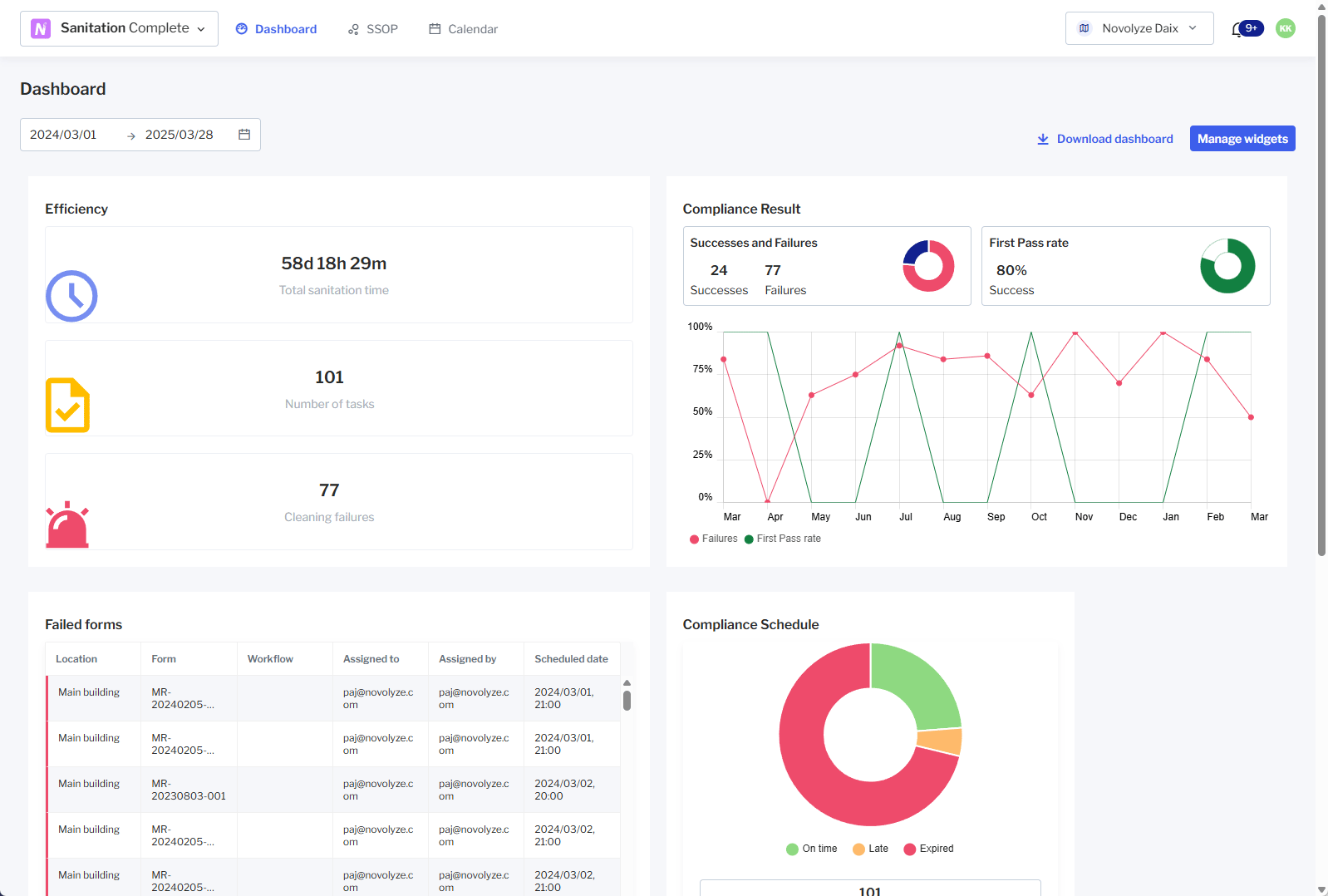

Novolyze’s Sanitation Complete software solution enhances the effectiveness of both green and traditional chemicals by digitalizing Master Sanitation Programs, including environmental monitoring and task management. This comprehensive approach ensures that sanitation practices are optimized, aligning with food safety objectives and promoting sustainability.

Digitalizing sanitation schedules and SSOPs ensure effective application and traceability to enhance overall sanitation efficacy. Photo courtesy of Novolyze

CIP systems need to use the right chemicals for the application — such as in dairy, which has its own set of cleaning chemicals to clean pipes and equipment. System integrators and chemical suppliers can help with the specific chemistry needed. Photo courtesy of Wayne Labs

On the subject of biodegradability, all Diversey cleaning products meet biodegradability requirements, according to the EU Detergents Regulation (EC) No 648/2004, says Fabrizio Tardioli, associate director, global marketing food and beverage at Diversey, a Solenis Company.

“Sustainability is top-of-mind for many customers and consumers, so we are making notable efforts to develop and commercialize solutions beyond these regulations, adopting solutions and raw materials that have an even better sustainability profile versus the previous ones — for example, utilizing products that are coming from renewable sources or are 100% biodegradable,” Tardioli adds.

The market demands non-toxic chemicals (or chemicals that present less of a hazard for operators) and more environmentally friendly chemicals and products, Tardioli says. “In the food and beverage industry, sometimes we need to deal with extremely heavy soils and contamination where the possibility to utilize very mild chemistries is limited. If we specifically talk about Listeria spp and monocytogenes, we need to clarify a few points. The first one is that as a [bacterium], listeria is not difficult to kill, so we do not need any particularly harsh chemistry or super-aggressive product to kill it. However, listeria is extremely difficult to eradicate from food processing factories, and it requires many different practices and solutions to mitigate it and control it — from cleaning and sanitation to GMP, hygienic design, [and] water and humidity control.”

Relying and focusing on only one C&S approach will most likely lead to failure to control Lm on the production floor, Tardioli says. The focus should not solely be on the nature of the detergent or the sanitizer/disinfectant, but rather the whole site’s procedures and risk mitigation practices. In the recent Boar’s Head outbreak, the root cause was “…meat and fat residue from the previous day’s production on the equipment, including packaging equipment.” Other instances included dripping condensation “on exposed product” and “cracks, holes and broken flooring that could hold moisture and contribute to wet conditions.”

“From this limited information, it is already clear that there was more than one aspect of the site’s procedures that was not fully under control: inadequate cleaning, monitoring and verification, water and condensation management, facility management and hygienic design, to mention a few areas,” Tardioli says.

Therefore, if a biocide product meets the local regulation, whether “green” or not, this will be absolutely fine to control listeria, but only if all of the surrounding aspects (cleaning, monitoring, facility, GMP, hygienic design, etc.) are also properly managed, Tardioli adds.

Listeria and RTE Environments — No Magic Bullet

We have to acknowledge that there is no silver bullet for controlling listeria. In a ready-to-eat meat processing environment, controlling listeria requires a multi-pronged approach that includes good manufacturing practices and sanitation procedures, strong environmental monitoring and effective sanitary design process controls.

Protein processors would be wise to adopt a cross-functional approach to decision-making that includes procurement teams in the sanitary design strategy. That way, they can proactively incorporate sanitary design principles into key equipment decisions, e.g., by researching whether a new piece of equipment can be easily disassembled and cleaned effectively. This proactive approach produces much better results than retroactively applying sanitary design principles to equipment after it arrives on the factory floor.

If processors find themselves dealing with a higher-risk piece of equipment — one that’s difficult to clean and sanitize thoroughly — they should place that piece of equipment on a more rigorous and frequent C&S schedule. This heightened protocol should involve using more powerful chemistries, thoroughly disassembling equipment during cleaning and sanitization, applying increased environmental swabs to the area and, if necessary, limiting access to the equipment.

—Rich Walsh, Senior Staff Scientist, Ecolab

Electrolyzed Water: Practical for Food and Beverage?

Electrolyzed water, i.e., generating hypochlorous acid, is recognized for its antimicrobial properties and utilized in various sanitation applications, says Novolyze’s Khinouche. “Its effectiveness can be comparable to traditional chemicals, like peracetic acid or NaOH, depending on factors such as concentration and application method. Electrolyzed water is particularly suited for surface disinfection and environments where chemical residues are a concern. However, its cost-effectiveness varies based on implementation scale and operational considerations.”

“This method is not more effective than traditional chemicals, neither in cleaning nor in disinfection,” cites Diversey’s Tardioli. “It has the advantage of local production versus storage of formulated chemicals; however, it also requires the investment costs for the generator and electricity consumption. In some circumstances, the solutions generated can also come with a serious risk of corrosion due to elevated chloride levels.”

“The best application for electrolyzed water occurs in a pool, spa or premise plumbing scenario,” says Rich Walsh, Ecolab senior staff scientist. While some have tried within food and beverage contexts, its undesirable side effects typically outweigh its utility as a cleaning solution. Electrolyzed water requires high levels of sodium chloride, or salt, to function. Because the chlorine (and in turn, hypochlorous acid) generated from this process is not a complete conversion, the end result is a copious amount of salt in the system at all times. This salt solution splashes and sprays onto nearby surfaces, and after the water has evaporated away, the remaining salt becomes highly corrosive to many common materials — even stainless steel. In addition to shortening the usable lifespan of core equipment, this corrosion creates the ideal conditions for pitting, which creates harborage points for microbiota and increases the risk of a serious microbiological event.

“Finding the most effective and sustainable cleaning and/or sanitation option heavily depends on context,” says Joy Herdt, Ecolab senior staff scientist. “Within the food and beverage space, this context varies significantly based on what’s being manufactured or processed. For example, producers of certain food types, such as cereals, nutrition bars, grains or nuts, will want to contain and control water when cleaning and sanitizing to minimize the risk of water becoming a vector for microbiota, which may include pathogens. This is what we’re talking about when we talk about dry cleaning — a methodology wherein the tightly controlled application of cleaners and sanitizers limits the amount of water (and water-related risk) in the cleaning and sanitization processes.”