NovemBER 2022

For Food Safety Interruptions

Be Prepared

Wayne Labs, SENIOR Contributing TECHNICAL EDITOR

Today’s processing equipment—often skid mounted—is typically enclosed and elevated a minimum of 4 in. or more off the floor to facilitate cleaning. Therefore, it can withstand minor incursions of flood water without contaminating product. Photo courtesy of Imagemakers, Inc.

Murphy’s Law or its corollaries are not your ideal thoughts when it comes to food safety. However, when storms or other upsets to production occur, Murphy seems to go to work wreaking havoc.

Last month, we looked at several extreme weather-related events that could affect and potentially shut down your operation—anywhere from a few hours to possibly weeks or months. Weather-related events, power interruptions and other issues can add up to serious food safety problems if there isn’t a plan or strategy set up in advance. We look at a few food safety issues, though the list is not exhaustive.

Water as a Disruptor

Water: life-sustaining compound, key ingredient and rinse-step for many food and beverage processes—and a major part of any cleaning cycle. However, when we think of water as a major disruptor, we usually think of flood-waters directly impinging facilities and affecting plant operations. But it can be just as damaging in other ways.

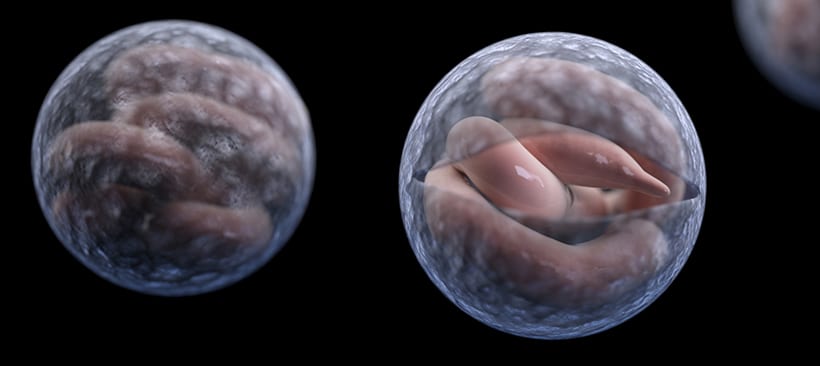

What if your community’s potable water supply is contaminated with Cryptosporidium? Not pleasant, putting it mildly. In 1993, the city of Milwaukee all of a sudden faced staffing issues in hospitals and public schools due to a common illness. During a two-week period, more than 400,000 people became sick with GI-related problems, and later on, while no deaths were reported among the general population, researchers reported an estimated 100 deaths among HIV patients within a six-month period.1

After some extensive research, the city’s potable water supply was found to be infected with Cryptosporidium, a microscopic parasite. Unfortunately, the bug couldn’t be detected by standard tests of water quality, nor could it be killed with the typical levels of chlorine used in water treatment facilities. And incubation of the bug can range from one day to two weeks, with onset of symptoms generally taking a week, making it harder to track.

Imagine a food or beverage plant using this contaminated water as an ingredient or as a rinsing agent for produce where no kill-step is involved. Thankfully, Miller Brewing Company cold-filters its beer, and its filters’ screens were fine enough to remove all of the Cryptosporidium, thus averting contamination. Canning facilities heated their products at high temperatures, so there was no contamination to canned products.

Cryptosporidium is a microscopic parasite that causes the diarrheal disease, cryptosporidiosis. Both the parasite and the disease are commonly known as “Crypto.” Photo courtesy of U.S. CDC

Potable water can have other potential problems. For example, public water utilities may occasionally find it necessary to do some line work or repairs, which can cause potable water discoloration when repairs are finished and water is flowing again; most likely, homeowners have experienced this occurrence at some point. Sometimes processors will be notified before the work is done, how long it is expected to take and whether any interruptions will occur. The best way to avoid any problems could be to shut down operations until the work is finished. While the work is proceeding, make sure the incoming water valve is shut off completely. After the work and water flow is restored, processors will want run the water to ensure there is no discoloration prior to use, says Kara Scherer, lead food safety specialist for the Dennis Group. “Dependent on the reason, water testing may be required.”

Of Floods and Supply Chain Issues

OK, a flood in the Carolinas isn’t your problem since your processing plant isn’t located there, right? Wrong, says Dr. Bob Strong, noted SAI Global food safety expert and consultant, in a recent webinar. Referring to Hurricane Florence some years ago, Strong notes that 5,500 pigs were drowned—along with more than 3.4 million chickens. Well, it’s not your problem unless those pigs or chickens were part of your supply chain. Most likely, your supply chain is flexible enough that you will be able to divert to another supplier and keep your product in the market.

“The only good news here,” says Strong, “is it doesn’t take long to get pigs at all—and to get chickens. But it doesn’t happen overnight. So, what would you do if this was an example of what happened to one of your suppliers, even though you may not necessarily have been involved with the flood yourself?”

Keep in mind that switching to a “new supplier” means that supplier will need to be vetted and qualified in terms of food safety—and possibly affect your labeling if ingredient changes are made due to a new supplier’s ingredient list.

Modern packaging equipment is typically elevated off the floor such that minor ingress of water will not cause problems. Photo courtesy of Imagemakers, Inc.

Of course, supply chain issues can be caused by local weather events, but as we experienced during the pandemic, there can be several other reasons for delays. Some processors may think that having extra inventory in stock is a way to prevent shutting down a line due to lack of ingredients. But is building up inventory a good solution?

“Food processors should only build up inventory of an ingredient if they can afford the upfront cost, have the storage space, and if they can use the ingredient within its shelf life,” advises Scherer. It’s always best to have multiple approved suppliers for an ingredient. Being single sourced may lead to production delays. Typically, most manufacturers will have one vendor they prefer to use and will get 80% of the material from. Procurement typically has the secondary sources making up the other 20%, says Scherer.

When Flood Waters Enter

Last month, we looked at some pointers to minimizing flood damage based on changes that can be made external to the building—and changes that can be made to the building. For example, many steps can be taken to harden facilities in hurricane areas, says Russ Schertz, project director, NextGen Ag, Black & Veatch. “Besides the usual generators, the dock doors are raised for high winds with smaller windows and insertable bracing. These facilities have to plan for getting employees to the site and having facilities for employees to stay if ‘trapped’ overnight.”

But even after taking all preventable measures, there is always the “100-year” or the “500-year” flood that—in spite of how you’ve prepared—will still cause some water ingress. This raises the question: Should processing equipment be elevated off the floor (more than the usual amount for floor cleaning) to prevent contamination or damage due to water ingress?

“You can’t always plan for how high flood waters will be,” states Dennis Group’s Scherer. While propping equipment up off the ground sounds like a great idea, it may not be the best for everyday use for something that may never occur. If a flood does occur, having an uncontrolled water event policy in place will help streamline the process for remediation. Performing a full clean on the equipment and area, as well as environmental swabs, will be required to ensure product safety prior to startup. Raw materials and finished product will also need to be assessed and discarded if affected by the flood, advises Scherer.

Production equipment may not be so easily elevated, but scoping out the warehouse may be a good idea. Strong suggests in his webinar that processors may want to get packing materials and ingredients off the immediate ground level if possible and even recommended moving inventory to a warehouse on higher ground if there is ample warning and space available.

Power Outages and Interruptions to Cooking Processes

Power outages can cause food safety issues at several levels. Obviously, production can be halted, which will interrupt any cooking processes, and power loss to refrigeration systems poses a larger problem.

“Having a backup generator for an entire facility is very expensive and not commonly done,” says Scherer. Typically, a facility will choose to take the losses from the outage for the WIP, while ingredients and finished product with temperature requirements (refrigeration/freezing) will have the backup generators.

One way to keep critical packaging materials high and dry is to store them directly above the packaging area—and convey them down when needed (a spiral conveyor is used here to save space). Therefore, any flood waters never reach the stock of packaging materials. Photo courtesy of Wayne Labs

“This is the most cost-effective means of not losing everything in your facility because of power outages,” adds Scherer. For long-term outages, weighing the options for renting extra refrigerated/freezer trailers or using offsite cold storage facilities may be needed to save that product.

Interruptions to the cooking process can occur due to power loss, valve or heat exchanger failures, boiler issues such as low steam, and any number of other malfunctions. For short duration interruptions or undercooking, the system should be shut down and all product removed from conveyors. If undercooked product was chilled properly, it may be able to be reintroduced to the cooking process once all systems have been properly restored. If product is recooked when systems are back up, it will need to be checked for quality and food safety before it is considered finished-goods to be packaged.

Longer-term cooking interruptions will require consideration of several variables, which may include repurposing product. Depending on application and FDA/USDA rules, processors need to have plans in place for these situations. More detailed information related to meat processing can be found in an article entitled, “How to Deal with a Major System Disruption in a Meat Processing Facility.”2

The “At-Home” or Resident Environmental Bacteria

If a visitor or worker has tracked bacteria into the plant from outdoors, that’s often nipped in the bud by boot washers and/or a change of shoes—and by clean-up procedures. But once a bacterium such as Listeria Monocytogenes has decided to move in permanently—that is, be “resident”—then the problem is much more serious. as Blue Bell Creameries discovered back in 2015.3

With the persistence of resident bacteria like Listeria, it’s easy enough to understand why company officials might be inclined to tear down the building and start anew. That’s a little extreme, however, but until the source is found, no product should leave the building.

“Tearing up, cleaning and rebuilding because of the presence of an environmental pathogen should be a last resort,” says Dennis Group’s Scherer. The best way to manage pathogens in your environment is using the seek-and-destroy methodology. Once you know where bacteria are living, you have a better means of control. Creating a robust environmental monitoring program with routine swab sites in high-risk areas and random sites based on conditions the swabber sees while in the facility is best practice. Also, having a policy in place for uncontrolled water events (roof leaks, condensation, flood) will ensure equipment is adequately cleaned and cleared prior to startup after an incident. Companies that tie in “having no environmental pathogen findings” into their KPI’s are leading employees not to seek it out so they can get that incentive at the end of the year, says Scherer.

“If Listeria is living in the drain system, which is likely, there are quat or sanitizer rings that can be placed in the basin,” adds Scherer. Drains in high-risk areas should be cleaned at a high frequency as well. With air handling systems, adequate preventative maintenance like filter and gasket changes should prevent water, oil and microbes from entering the air stream.

Floor drains are a perfect source for “resident” or environmental bacteria such as Listeria. Fortunately, there are solutions to destroying any living bacteria underneath. Photo courtesy of Wayne Labs

While not all bacteria are “resident,” it certainly doesn’t take much coaxing to invite the bacteria to stay awhile if a food processor disregards food safety altogether. Such was the case of Peanut Corporation of America (PCA), which shipped known Salmonella-infected product to major food processors. PCA’s officers are serving time in prison for their misdeeds—taking no action to stop Salmonella growth in their peanut paste products. See the section entitled “Back to Basics” in “Food Safety at the Crossroads,” FE, March 2, 2009. According to a January 27, 2009, FDA “483” form (FEI #1036857), posted on its website, several FDA-conducted observations at PCA’s Blakely, Ga., plant pointed to known positive tests for Salmonella, but PCA still shipped product from late September 2008 into January 2009.

The FDA found just about every mistake that could be made to prevent a bacteria growth in-house. FDA’s document found “failure to maintain equipment, containers and utensils used to convey, hold and store food in a manner that protects against contamination.” Further observations revealed an ineffective roasting stage (a critical control point (CCP) to kill pathogens), mold growth on ceilings and walls, gaps in A/C intakes on the roof where water leaked in over production and packaging areas and other exposed openings to the outdoors and its critters.4

Labeling: Biggest Cause of Recalls

Three problem areas that arise in packaging and labeling include: misprint, mispack and misread. Any of these, if not corrected, can lead to recalls. Derrick Colyer, business development manager and former automation engineer at E Tech Group, a Control System Integrators Association (CSIA) Certified Member, describes these problem areas in more detail.

Misprinting can result when printing and applying on labels or cases. Whenever printing or labeling is part of a solution, checking the outcome—and as a result—rejecting based on that check is must. “We partner with a variety of quality checking technologies and can integrate this as a standalone solution, or our preferred method, integrate the solution into the line control packaging solution,” says Colyer. This allows for easier data traceability and data communication for efficiency numbers and even troubleshooting.

Mispacking can involve a number of issues. For example, this could be applying a crooked label, or a skewed cap, or broken bridges on a safety cap, or other. If any of these could trigger a recall, or a negative perception from the consumer to your brand, then a quality reject solution should be introduced into the packing line.

Misreads also present a problem. If you have a quality solution and you can’t guarantee that your quality check has passed, then you should reject that product. These rejects very well could be good product and can either be rerun through the quality inspection system, or visually checked, and if passed can be re-introduced to the line. If multiple miss-reads are occurring, then maintenance should be performed on the quality device(s), adds Colyer.

A potential food safety problem, evaporators are often forgotten, but still need to have filters changed, drainage pans cleaned and drain tubes checked for clogs to decrease the likelihood of bacterial buildup. Photo courtesy of Ross Van Pelt, RVP Photography

Besides the mechanical issues that Colyer described, Dennis Group’s Scherer emphasizes that labels must contain the right information. “The most common allergen preventive controls used by manufacturers involve label review. Typically, upon receipt, someone is reviewing the label content as accurate, ensuring the nutrition panel, ingredient statement and allergen statements are correct before releasing for use in production.”

The label is then reviewed again during its use on the production line. This process can be done manually or by use of a vision system, adds Scherer. While there may be human error to fault with these preventive controls, there are many other factors that should be considered than just label verification.

Scherer lists other preventive controls that may reduce recalls:

1. Approval of ingredient changes (including recipe changes or new suppliers). Procurement may know about a change to a supplier or a slight recipe change and approve it without considering the change to allergens.

2. Using a third-party service to create your ingredient statement or to at least verify it. While it may sound simple to write out all the ingredients you use from highest to lowest, most ingredients used in food manufacturing also have their own ingredient statements. If a manufacturer forgets to carry them over, they then have an incorrect label.

3. Control of overflow. Many line disruptions, like an equipment failure, may lead to removing product from the line and adding it back at a later point. If control is lost when product goes back onto the line (mixed with wrong product run, added back to wrong processing line), it could lead to product being packaged with the wrong label.

Crisis management team sets direction in emergencies

Whether it’s a flood, fire or simply contaminated product that gets out the door, having a crisis management team can be crucial in getting back on line and/or initiating a recall. Here are some tips offered by our interviewees.

1. A member from each department should be represented on the crisis management team since emergency situations will affect everyone differently.

2. The team should appoint a leader with great communication and problem-solving skills.

3. A plan should be set in motion within an hour of an incident. Once a plan is in place, team members may need to call in a consultant to help address those action items from the initial meeting or for a second opinions.

4. To be effective at crisis management, the first and most important criteria is to be able to respond to physical disasters. Being able to respond with CPR skills or basic first aid skills are a must.

5. Some larger companies train their team to have a local fire response team. They have proper PPE and are able to respond to situations faster than most local fire departments are able to arrive.

6. Work with local authorities to develop a plan if this is an avenue your company would like to pursue.

7. Practice for emergency situations. Failing to plan is planning to fail. Derive a plan, communicate the plan to the whole team and create planned drills and random drills. Practicing hectic situations will make real emergencies easier to navigate.

8. These practice drills should include mock recalls to be sure there is an effective and working recall strategy in place.

9. Maintain a spare OT hardware list for recovery from emergencies. Work with a system integrator or outside consultant in setting this up.

10. Work with your insurance provider and your legal consultant to see if premiums will be lower by having a crisis management team available at a moment’s notice.

Observe All Processes from Beginning to End

Finally, when bad things happen, knowing the state of all your equipment is important in getting back on line. It can’t be underemphasized that periodic testing, calibration and maintenance play a crucial role in the manufacturing, packaging and handling of food and beverages. According to Benjamin Langton, senior offer manager at Interstates, a CSIA Certified Member, calibration activities performed on a frequent schedule helps to reduce the risk of error, ensuring highly accurate, traceable and repeatable measurements throughout the production process. “Since instruments are the best indicators of the health of your facility, regular calibration and testing can improve efficiency, uptime, and extend the lifespan of devices,” adds Langton. FE

Resources:

[1] “Cryptosporidium in Milwaukee’s water supply caused widespread illness,” Healio, Infectious Disease News, September 2007

[2] “How to Deal with a Major System Disruption in a Meat Processing Facility,” Food Safety magazine, BNP Media, October 18, 2017

[3] “Blue Bell knew about Listeria problem in 2013,” FE, May 13, 2015

[4] “Food Safety at the Crossroads,” FE, March 1, 2009

“A Guide To Food Safety In Emergencies,” Connecticut Department of Consumer Protection, https://ccetompkins.org/resources/a-guide-to-food-safety-in-emergencies

NOVEMBER 2022