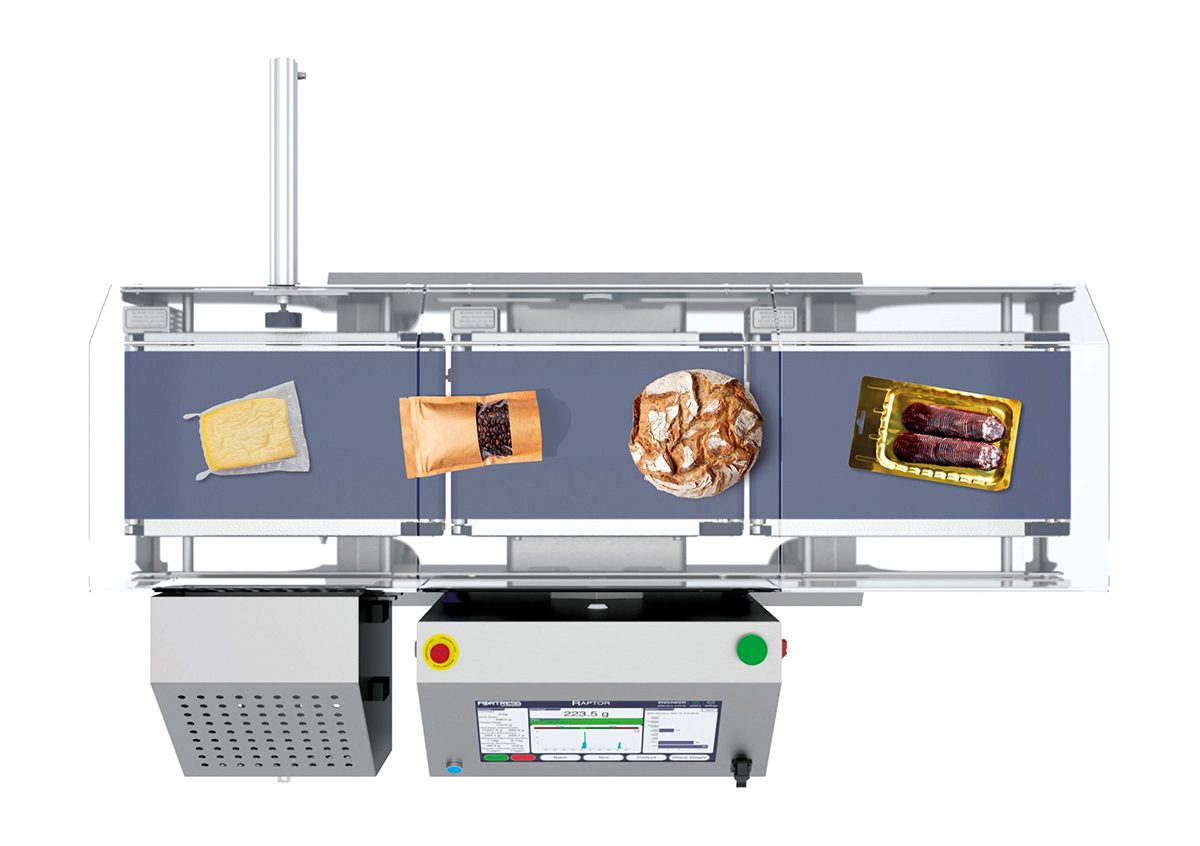

Raptor Checkweigher delivers premium inspection and weight checks at a competitive price point. The checkweigher targets operational inefficiencies, including upstream product giveaway, non-conforming food packs and packaging waste. Easily integrated with existing metal detection equipment, Raptor delivers dynamic weight monitoring with minimal customizations to existing product feed and packing lines. The Raptor introduces high-end weighing algorithms, driving down expensive overfilling. Providing the most accurate high speed results in line with multiple global weighing legislative requirements, the in-motion, three-belt checkweigher captures thousands of sample readings of individual packs every second. By digitizing the checkweighing process, manufacturers can rapidly achieve productivity gains and save cost in product giveaway. The checkweigher can operate as a standalone unit or for maximum efficiency.

Learn MoreCheckweigher targets operational inefficiencies