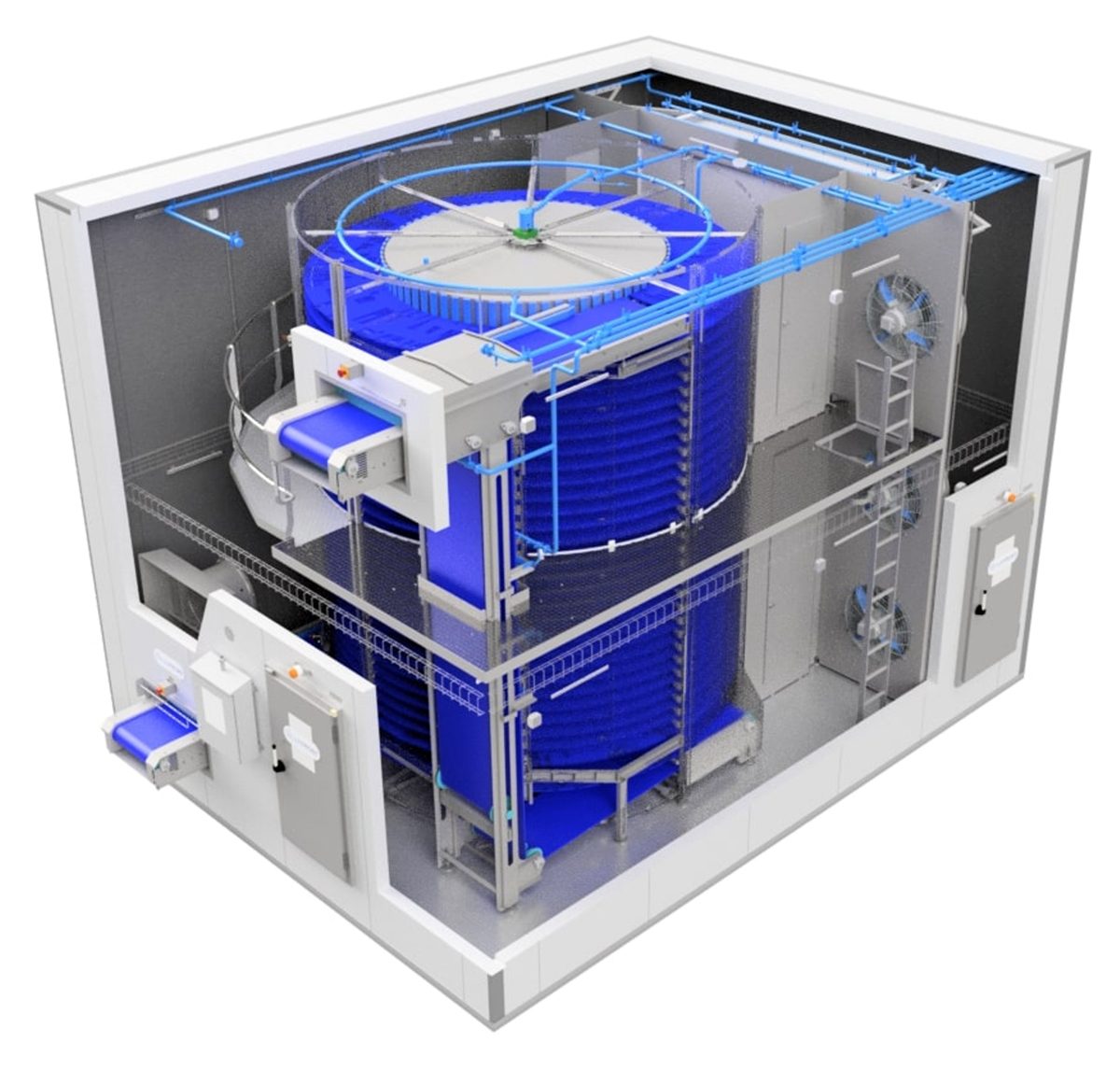

To meet the rising demand for its seafood products, Båtsfjordbruket invested £7 million in a growth development plan, which includes a site extension and new processing equipment for its new frozen fish fillet production line. Photos courtesy of Starfrost

Based on the northern side of the Varanger peninsula in Norway, Båtsfjordbruket is a subsidiary of the large seafood corporation Insula AS. The group’s primary focus is the development, processing and sale of fish and seafood products across the Nordic region. Insula’s corporate portfolio consists of a number of seafood companies in Norway, Sweden, Denmark, Finland and Iceland.

To meet the rising demand for its seafood products, Båtsfjordbruket has invested £7 million in a growth development plan. The recent expansion includes a site extension and new processing equipment for its new frozen fish fillet production line.

Among the new equipment is a spiral freezer. Cooling equipment manufacturer Starfrost designed an efficient spiral freezer that features cutting-edge sanitizing technology, which enables the seafood firm to increase product throughput and fully automate freezing processes within the new production line.

A new spiral freezer from Starfrost has increased production capacity by 35% at seafood processor Båtsfjordbruket

Cooling equipment automates freezing processes at Nordic seafood company

Cooling equipment manufacturer Starfrost designed an efficient spiral freezer that features cutting-edge sanitizing technology, which enables the seafood firm to increase product throughput.

Frank Kristiansen, CEO of Båtsfjordbruket, says, “Our recent investment to expand our factory and increase product capacity provided a great opportunity to implement new freezing technology in our processing line.” He says they selected Starfrost as their freezer supplier based on company reputation and global service support. “Starfrost equipment is renowned for its reliability and we were happy with the specification they provided, which supports our focus for high efficiency and high performance within our factory lines."

The Helix spiral freezer is a fully automated system that minimizes contact handling. This, combined with a seamless enclosure construction that features an automated cleaning system, delivers improved hygiene safety within production. “The high-tech efficiency of the freezer means we are able to produce more frozen seafood product in a more cost effective way than we were before. Our processing times have been reduced and we have boosted capacity by 35%, with plans to increase this figure once we are running at maximum production capacity,” Kristiansen says.

The compact Helix spiral freezer with horizontal airflow technology provides consistent, controlled freezing that is gentle on delicate seafood products, like the ones at Båtsfjordbruket, a subsidiary of Insula AS.

Although compact, the freezer processes 2,500 kg of fish fillets per hour, including cod, saithe and haddock, and its horizontal airflow technology provides consistent, controlled freezing that is gentle on delicate seafood products. The spiral freezer houses 170 m2 of stainless steel belt, which enables large capacities of seafood products to be frozen within a small factory footprint.

Controlled with an intelligent HMI screen, the freezer features programmable settings for precise temperature reduction and freezing times for individual products, which is both energy efficient and flexible to the seafood processor’s existing and future production requirements.

“The Helix spiral freezer installed at Båtsfjordbruket has provided significant efficiency and throughput benefits, thus enabling a maximum return on investment,” says Jonathan Fox, export sales manager at Starfrost. “The stainless steel and fully accessible design ensures highest hygiene levels and ease of maintenance. The addition of a Clean in Place (CIP) system delivers a repeatable, cost effective method of cleaning and sanitizing. Latest advancements in Starfrost’s CIP technology have enabled a reduction of water usage from 100 liters per minute to 8 liters per minute. The innovative new design delivers the highest hygiene levels whilst decreasing the volume of detergent and sanitizer.”

For more information, visit www.starfrost.com FE