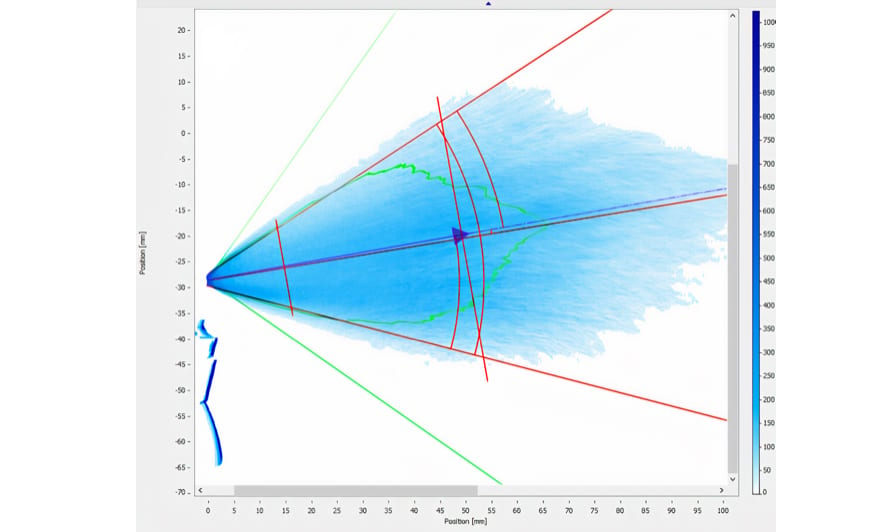

New measurement technology uses optical techniques to capture spray behavior at high speed (around 7,500 images per second). Made up of front and back radial lighting, camera and suction system hardware, the integrated software produces 30-second videos of spray movement for analysis, equivalent to 0.1 seconds in real time. The process provides detailed information on axial plume spray, including the particle distribution as well as the angle, diameter and length.

Spray pattern diagnostics