Packaging, Automation

Changing Consumer Attitudes on Sustainability

Setting up a new line or incrementally adding automation is easier when you know your product and expectations.

Tips for Building

Food Packaging Lines

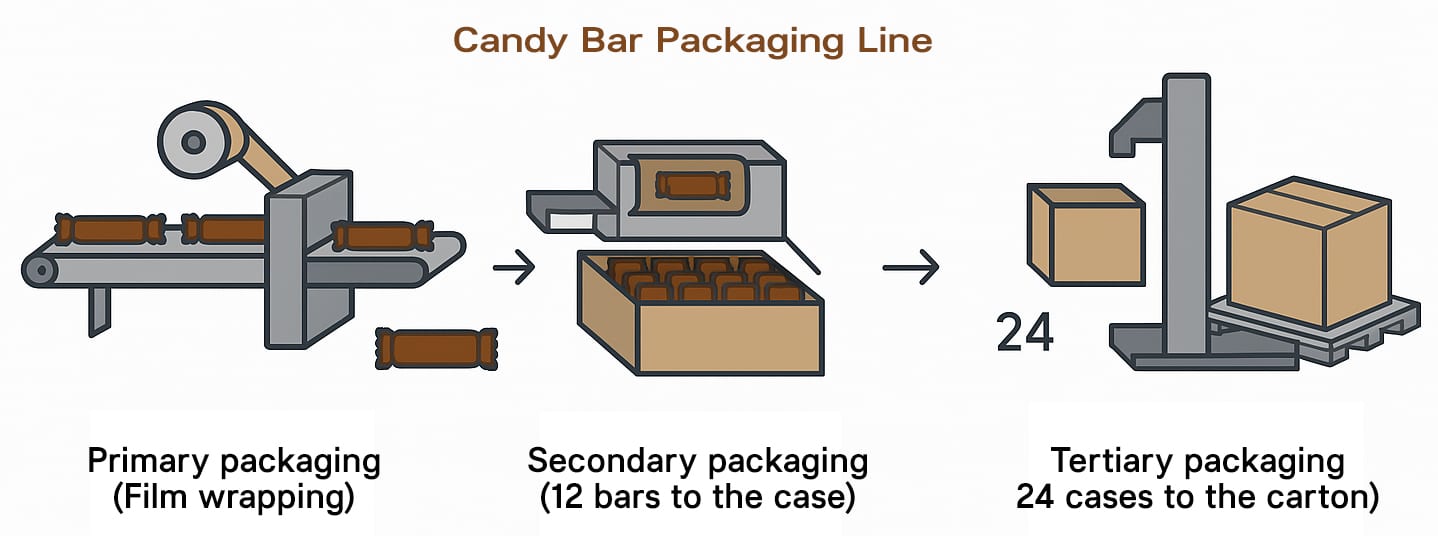

Typical packaging lines have three or more successive levels of packaging: primary packaging, say, film wrapping a candy bar; secondary: placing 12 wrapped candy bars in a case; and tertiary, placing 24 cases in a carton and then palletizing them. Robots may or may not be used at different stages depending on the level of automation. If you’re fortunate enough to have a brand-new, fully integrated and automated line with the right conveyance throughout, you probably have fewer problems than if you’ve incrementally added automation over the years.

However, being able to define your products and your packaging wants and needs are key to planning new lines or incrementally adding capabilities to existing lines to avoid slowdowns and stoppages in the future.

Define Your Product and Needs for a New Packaging System

“A well-defined product portfolio is essential for designing a packaging system from scratch,” says Brigadare Manradge, CRB process engineer. “This portfolio should include detailed specifications, such as product sizes, production rates and critical quality parameters. With this foundation, we can not only develop an effective packaging system but also anticipate potential product changes. This foresight allows us to select or design equipment that can adapt to future modifications, ensuring long-term flexibility and efficiency.”

Even more specific product details will help in planning, says Josh Becker, Harpak-ULMA Packaging bakery and confection segment manager. “What is the product, what are the product characteristics (dimensions, rigidity, fresh, frozen, sticky, hard to handle, flat on the bottom, etc.)? What is the total number of products per minute arriving to the packaging system and how many products go into each primary package? How are the products arriving at the packaging system (single file, in rows, in a chaotic fashion, short edge leading, long edge leading) and what is the desired primary package?”

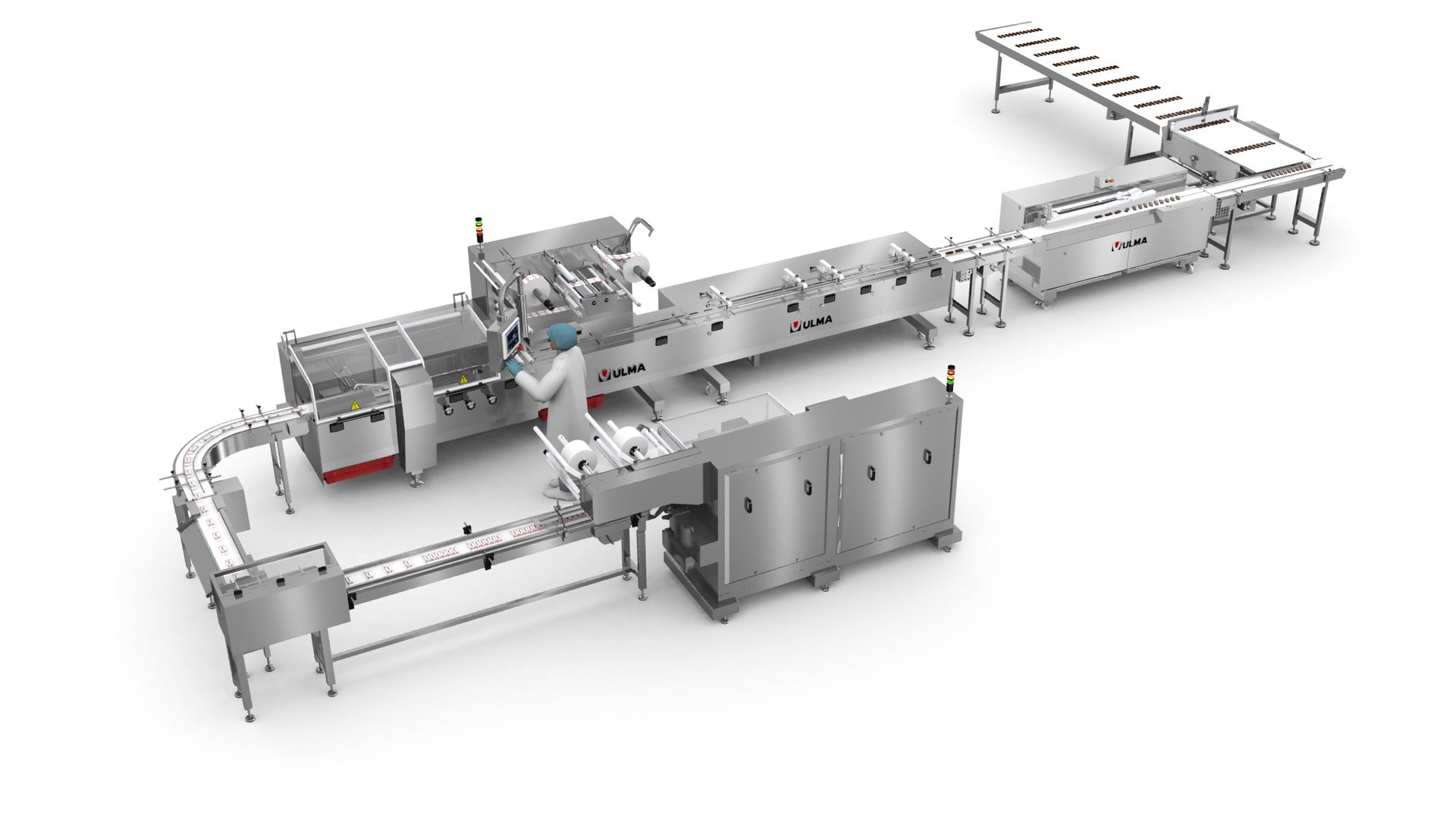

Bars are lined up for automatic feeding into a conveyor system leading to packaging in a pouch. Photo courtesy of Harpak-ULMA

By Wayne Labs

A complete bar packaging line includes primary packaging and secondary packing equipment plus equipment to line the bars up in correct position for packaging. Photo courtesy of Harpak-ULMA

Common Kinks and Hints to Primary Packaging Woes

Common kinks often depend on the operator and maintenance personnel, as well as their individual skill, training and teamwork. Many issues arise when new personnel are learning the equipment. Long-term or chronic issues are best resolved through collaboration between plant operations, the maintenance team, packaging SMEs and OEMs working together.

→ When raw material components meet quality specifications, many persistent issues can be traced back to contamination sources within the packaging system. Identifying and controlling these sources is key to resolving recurring kinks.

→ Film tears and wrinkles lead to poor seals. Avoiding these requires regular film path alignment checks, auto tensioning systems, etc. Storage of films in the proper conditions can be overlooked. However, humidity can warp film rolls, which affect performance.

→ Poor seal integrity is another common kink. Keeping jaws clean, verifying temperature profile and seal pressure are easy fixes that can help maintain efficient operation. To avoid/minimize mis-threading, visual threading guides and SOPs for operators can help.

→ With horizontal flow wrappers, consistent flow and size of product is needed. If this cannot be guaranteed or it is not practical to improve the product or feed system, a product inspection and rejection system can be used to improve performance of a wrapper. This rejected product can then be refed manually into the system so as to reduce overall waste.

→ Singulation of products from upstream processes, therefore, selecting the proper product distribution system for the type of product, size of pieces and rate is critical.

→ Film control and product control are the biggest “kinks” or areas to ensure are operating properly. As soon as film control/tension issues arise it causes a domino effect with misalignment of film registration, misalignment of code date on the package, etc. Product also needs to be fed properly and consistently to stay “on pitch” for the wrapper to be highly efficient.

Once you have that information you can determine the machinery type and possibly the total number of machines required for the production capacity, Becker adds. A good product specification spreadsheet with all the above information is essential, as well as pictures of the product and packaging material specifications. It is also good to know any future product sizes that should also be considered for this packaging line.

Some additional considerations include the following, according to Rick Graff, Gray AES principal packaging engineer:

- Sanitation requirements for the type of packaging operation (i.e. primary filling versus end-of-line pallet handling)

- Environment required for the product — temperature, humidity, washdown

- Required throughput rate of the overall system

- Range of sizes, speeds, patterns required.

- Is a buffer or redundancy needed — is this system directly linked to an upstream process that cannot stop if a packaging machine faults?

When planning and designing a packaging system from the ground up, especially when plenty of space is available, it’s important to approach the process with a clear goal in mind and work backwards, says Nick Basham, regional sales manager for Magnum Systems, Controls Integration Business Unit (ECS Solutions) a CSIA-Certified member. “We start by asking key questions about the who, what, when, where, why and how of the project. Consider who will operate and maintain the system, who will be affected by it and who your current and future customers are. Then, consider customer expectations for quality and type, management’s needs for process visibility and potential opportunities for growth or diversification in the future. Many plants limit themselves by focusing on a single product or packaging type, but adding packaging capabilities can unlock new revenue streams and industries.”

Timing is another crucial factor — determine when the system needs to be operational, as projects can take anywhere from eight weeks to six months, depending on complexity and automation levels, Basham adds. Early planning and foresight are essential for staying on schedule and fulfilling delivery commitments. Additionally, consider the direction of the business and whether automation is a feasible option now or in the future. The “why” behind the project is perhaps the most important question: why is this investment being made, and will it benefit the business and its employees in the long run? Finally, address the “how” by assessing the financial impact, expected ROI, maintenance needs, desired level of automation and daily processing requirements to meet customer demand. By examining these factors comprehensively, you can design a packaging system that is efficient, adaptable and aligned with your business goals.

Finally, the opportunity to design a system from scratch provides a unique opportunity to “do it right” the first time, says Rahul Nehete, Gray AES vice president – packaging. “Often times, dollars drive decisions at a very early stage, however, in the lifecycle of the production line, this myopic view can cost multiple folds over in operational inefficiencies. During the initial phases of planning, deliberate planning based on long-term business objectives should drive the throughput goals, SKU variability and future expansion considerations. Design with flexibility in mind, which drives you to develop scalable layouts and allows you to account for new pack sizes or materials.”

During the design phase, a deliberate emphasis on aligning packaging rates with processing capacity upstream and warehousing requirements downstream ensures seamless connectivity between production zones, Nehete adds. Another aspect worth consideration is the use of high-quality simulation models to run what-if scenarios that provide directional guidance instead of guessing the effects of changeovers, product variability, inefficiencies etc.

Incrementally automating one phase of a packaging line. Graphic by Wayne Labs.

Common Kinks in Secondary Packaging (Case Packing)

→ Cardboard dust is a significant source of contamination that can reduce uptime and overall equipment effectiveness. Establishing a quick, routine cleaning process to remove cardboard dust is essential for maintaining long-term, high-uptime operations.

→ Typical issues range from glue/tape fails and product jams/misalignments. Regular calibration and maintenance of glue heads plus the use of guiderails and balancing flow are typically beneficial in addressing these issues.

→ From an overall line standpoint, throughput imbalances/bottlenecks can occur when the case packer cannot keep pace with the wrapper or the palletizer. Right sizing the equipment and addition of buffer conveyance can help rectify these issues.

→ Some of the more frequent issues involve jams of bars at the infeed of a case-packer. Modern systems with bar collating systems seem to be the best solutions available today. Collation of bars prior to loading and maintaining positive control of the bar at all times is the best way to avoid jams and minor stops.

→ Out-of-spec products and packaging material can cause problems with cases opening or bulging. Tape must be applied properly to boxes and hot-melt glue must be at correct temperatures.

→ Case erection failures can happen due to worn-out suction cups or low vacuum pressure, which can be fixed by installing vacuum monitoring sensors and regularly replacing suction cups. Another common problem is product misplacement inside cases, often caused by timing mismatches. This can be resolved by synchronizing the product infeed with case presentation through servo adjustments.

In this simplistic illustration of a candy bar packaging line, assume that the primary stage (film wrapping) and the third and fourth stages (carton packaging and palletizing stages) are automated, but the secondary stage (case packing) is manual. What are the issues when the manufacturer wants to automate the case-packing stage — where humans now do the job?

Incremental integration requires careful planning, says CRB’s Manradge. “If the existing equipment has been well maintained and continues to meet throughput requirements, customer preferences and specific V-curve targets, it can often be integrated with newer subsystems. This is especially feasible when the component being replaced is a standalone unit and typically has some type of accumulation between it and adjacent systems.”

The packaging engineer needs to fully understand the capabilities of the existing equipment in order to ensure that the new equipment will be well utilized, says Joe Bradley, director – packaging, Gray AES. It is important to understand individual equipment center rates and create an ideal “V-curve” to optimize the efficiency of the overall packaging line. Each piece of equipment further away from the line bottleneck should typically be designed to be slightly (5-10%) faster than the equipment closer to the bottleneck.

- Let’s assume the following rates capability for existing equipment:

- (Primary) Wrapper – 240 bars/min (assume this is the bottleneck)

- (Secondary) Case packer – manual (12 bars/case) – 10 operators each pack 2 cases/min – 240 bars/min total

- (Tertiary) Cartoner – 1 case/min (24 cases/min, 288 bars/min)

- Palletizer – 2 case/min

In the system above, to specify the optimum new case packer, one should consider the “V-curve” of the existing system, Bradley says. In order to maximize the uptime of the bottleneck, the engineer should ensure that the case packer can run at least 5%-10% faster than the upstream wrapper. This would mean specifying a case packer that could run 21-22 cases/min.

For integration, the engineer should consider what is the overall line control being used? Is it a peer-to-peer system or supervisory system? What type of PLCs are being used. The engineer should attempt to use common platforms and hardware types where possible.

Control system compatibility is critical, Manradge adds. Each subsystem has its own communication protocols and limitations, so early verification by experienced controls integration experts is essential. Ultimately, capital budgets and spending timelines will dictate how much of a packaging line is upgraded and replaced, and which components to prioritize.

Primary packaging of candies into pouch. Photo courtesy of Imagemakers Inc.

People and Incremental Upgrades

Harpak’s Becker brings up an important point or two in automating the case-packing stage regarding operators, because people often perform more functions in less space — just not as quickly. “In my opinion the biggest opportunity to address when moving from a manual packing operation to something more automated is quality control. For example, you need to understand all the tasks the operators were doing, such as evaluating primary/secondary packaging quality, confirming carton/case count etc. The manual operators are often the last line of defense against ensuring all product/packages are correct.”

Becker adds: “When automating you need to consider what tools should be implemented, such as quality inspection systems (checkweighing, vision inspection for package quality — just to name a few). It is not that it is complicated, it is just something that is often forgotten so you have to consider it. The other issue is sometimes the manual packing area takes up less space than an automated system. You could also automate in steps, such as first starting with automated case erectors, then moving to automated packing and finally automated product inspection. It doesn’t have to be an all or nothing approach.”

Magnum’s Basham completely supports incrementally staging case packing. “We recommend incremental integration to address these challenges. Begin by introducing automation in phases, such as implementing semi-automatic casing, then conveyors, followed by automated infeed to the palletizer. Use integration gateways, like Ethernet-to-serial converters, and upgrade HMIs to connect older and modern control systems. Map out workflows to identify all handoff points, enabling the strategic addition of sensors, barcode scanners,or vision systems for verification. Standardize print formats in the control software to prevent font mismatches and inconsistencies between legacy and modern devices. Finally, utilize simulation tools like Emulate3D or Plant Simulation to validate speeds, layouts and buffer sizes before making physical changes, ensuring a smoother transition to a fully automated system.”

Secondary packaging of pouches of candies into a case placed by delta-robots. Photo courtesy of Imagemakers Inc.

Line Integration and Synchronization

Your packaging system should always be designed to operate efficiently at a higher rate of speed than the delivery of the product from the upstream process, says Harpak’s Becker. A rule of thumb in the past has been the Tmax of your packaging operation should be 20% over the max of the operation before it. In some applications like baking and confectionery manufacturing plants, you need additional capacity on your packaging line to avoid stopping the upstream process and to avoid finished product quality issues. In these instances, completely redundant packaging machines may be required, or larger buffering and accumulation systems may be a good idea. In baking, you want your accumulation system to be able to handle the full amount of product that would be in the baking process. A good packaging system has each unit operation integrated together so that the system can accommodate and divert product to the appropriate machine or buffer to avoid processing downtime.

All equipment and packaging sizes have their sweet spot, says CRB’s Manradge. The biggest improvement comes from having a data collection system that links speed with efficiency, making data visible and easy to understand. Many times, operators feel the equipment runs better but lack the data to support those observations. In some cases, the preference for a particular rate is influenced by practical challenges, such as difficulty loading a component, leading operators to slow down the equipment to allow more time for that task.

From the controls standpoint, the simple interlocking mechanism between upstream and downstream machines may not always be enough, says Magnum’s Gonzalez. To implement a more comprehensive integration, a centralized control system is required to handle the strategy of integration, adapting the speeds of each machine and the conveying system that transports products between the machines.

Because typically the integration is done with machines from different vendors, the standardization of the interface is extremely valuable. PackML is a standard whose adoption has been growing, making it easier to integrate not only to optimize the flow of products on the plant floor but also to integrate with MES and ERP systems.

A machine implemented with PackML is easier to integrate than those that have not been standardized, which require more effort from the system integrators, and sometimes the task becomes harder if the OEM locks the controller code, making it almost impossible to integrate.

Comon Kinks in Tertiary Packaging

→ Cardboard dust and/or glue nozzle control — failure to adequately manage either will lead to sources of contamination affecting the operation of these subcomponents.

→ Pallet quality variability — due to low-grade wood pallets, broken boards, etc. — can cause jams in palletizers. Specifying and adhering to quality pallet standards with suppliers can help minimize the issues.

→ Incorrect pallet patterns and/or weak corrugate design can lead to collapsed stacks or crushed product. Validation of carton strength for the load, and validation of pallet patterns to ensure even load distribution can help mitigate the issues.

→ Collating the cartons into the correct configuration

→ Consistently squared up and sturdy finished cases will maximize the efficiency of the palletizing system. Having good quality control over your operational and production processes is the key to maintaining a high level of packaging line efficiency.

→ Slip sheet or tier sheet misfeeds can be addressed by using vacuum verification to ensure proper sheet placement.

→ Pallet pattern misalignment, often caused by sensor drift or mechanical wear, can be resolved by regularly calibrating pallet pattern sensors and inspecting mechanical stops.

→ Inconsistent stack height, which may result from variable product dimensions, can be mitigated by standardizing incoming product tolerances or implementing checkweighers and vision inspection systems before palletizing.

Methods to Improve Operation

“Harnessing the true potential of simulation and digital twins can help verify the throughput, changeover times and buffer strategy before actual installations,” says Gray’s Nehete. At the same time instead of stopping at the initial design stage with simulation, keeping models updated with real world production data can help with continuous improvement.

If possible, large projects including multiple packaging system operations should be modeled, simulated and analyzed with an FMEA (Failure Modes and Effect Analysis) to ensure all the possible impacts of line failures are addressed and accounted for, says Harpak’s Becker. “This will help you determine the amount of packaging operation redundancy and buffer for your system. That helps pre-project production, but during and after production it is best to create a PM plan to address all wear parts of equipment to avoid line downtime.”

With installed systems, collection of data on individual equipment centers’ performance (uptime, minor stops, breakdown time) is a great way to set priorities for improving efficiency, says Gray’s Bradley. “Additionally, optimizing changeovers and training on changeover techniques is one of the best ways to improve efficiency. I’ve seen many situations where changeover efficiency is not emphasized, and it is often one of the largest causes of downtime. In addition, efficiency of startups after changeovers is not always measured, and poor changeovers and frequent adjustments after a changeover are another large cause of downtime.”

There is no substitute for observing problems in real time or capturing video to analyze key transformation points, says CRB’s Manradge. “These recordings can be studied and sent to others for broader input. Having the right team leaders and maintenance personnel is essential. By ‘right leaders’ I’m referring to the T2H (Trustworthy, Tenacious and Humble) leadership concept from the book Own the Gap. Plant leadership must provide a clear long-term vision that remains consistent year over year.”

To improve operations, it is crucial to implement preventative maintenance on a regular schedule, which can be integrated into the control system and guided by runtime and system efficiency metrics, says Magnum’s Basham. “This proactive approach helps keep equipment in optimal condition, reducing downtime and boosting overall efficiency. Adding a step verification system within your batch management process is essential. This system ensures each step is accurately followed, guaranteeing consistency and reliability in the final product, which is vital for meeting quality standards. Together, these strategies lead to smoother operations and higher-quality results.” FE