produce safety

A fresh look at

Produce safety still relies on three basic concepts: Keep it clean, keep it cold and move it quickly

Fresh fruits and vegetables have been part of humankind’s diet for millennia. This started with the hunter-gatherers and has progressed through to today where crops are grown and eaten fresh all over the world.

The early 1990s saw a new addition to what was available to consumers in the produce world: fresh-cut produce. For the past 30 years, consumers have had access to packaged precut vegetables of all kinds, leafy greens and fruits in their local markets. These offerings may include but need not be limited to dressings, shredded cheese, various toppings and other offerings that made enjoying fresh fruits and vegetables an easy option for people in a busy world.

One of the technologies that helped kick-start the fresh-cut industry was the development of modified atmosphere packaging. The Fresh Express helped pioneer this technology and also entered the fresh-cut market early in game. Dole, a major player in today’s market, brought its processing facilities in Yuma and Soledad online in 1991 and 1992, and the rest is history.

Richard F. Stier, contributing editor

Photo courtesy of Endress+Hauser

So, the fresh-cut produce business is really a young entity. The early years were ones of hard knocks for some; knocks which literally knocked some players out of the business. Among the challenges in the early years was that of educating long-time produce growers who jumped into the business that processing and handling cut produce was not the same as handling fresh head lettuce, cabbage or peppers. The simple message to these pioneers in the industry was framed by Seth Goldsmith of Dole back in the early days of fresh-cut: keep it clean, keep it cold and move it quickly. Of course, it always helps if one starts with good quality produce whether an operator is simply selling fresh foods or they are further processing it.

This seemingly simple formula was not always followed. The following quotes are from the San Francisco Chronicle in January 1998 in an article entitled, “2 Salad Processing Companies Sued for Food Safety Violations.”

Cattle were grazing next to the properties and there were no cleaners for food surfaces which were rough and hard to clean.

Water for rinsing the lettuce was dirty. There were no handwashing facilities for employees, who did not wear hair nets or gloves.

Image: Leafy Greens Marketing Agreement risk factors (www.lgma.ca.gov )

Because fresh produce has no kill step, safety must be maintained throughout the growing, harvesting and preparation processes. Photo courtesy of Getty Images/Pgiam

The companies that were the focus of this piece are no longer in business. Part of keeping it clean was—and remains—do what can be done to minimize the potential for microbiological contamination especially pathogen contamination. Allowing cattle to graze near a fresh produce operation is a disaster waiting to happen, since cattle and other ruminant animals are known to be carriers of pathogens such as enteropathogenic E. coli and salmonella.

The following three principles have served as the focus for food quality, sanitation and food safety programs since the outset. The industry has constantly worked to upgrade programs, the physical plant, improve sanitary design of equipment and all other aspects of operations. These efforts have also rolled back to their growers and the fields emphasizing good agricultural practices (GAPs) and enhanced programs for minimizing problems that could arise from the fields.

The biggest challenge

The greatest challenge in the produce industry is that the product is grown in fields or orchards, harvested and brought to the consumer with little or no processing. The cutting and washing of fresh-cut products mean they are minimally processed and this means there is no “kill step,” or in other words, no point in the process where microorganisms of public health significance can be eliminated.

The number of illnesses associated with vegetables, fruits, and other produce are significant. There have been a number of high-profile outbreaks associated with produce over the years. The 2006 spinach outbreak attributed to E. coli 0157:H7 was significant and turned into a great learning experience for the industry, as it underscored the importance of traceability back to the fields. 2011 saw a tragic Listeria monocytogenes outbreak attributed to melons that caused more than 30 deaths. The learnings from this were the importance of sanitary design and how it is essential to maintain water quality and temperature when cleaning melons.

As of this writing, there are several high-profile outbreaks in which the United States Food and Drug Administration (USFDA) has gotten involved: salmonella in packaged salad and a Cyclospora outbreak which has yet to be sourced. Cyclospora cayentenensis concerns are usually associated with leafy greens, fresh herbs and other fresh items such as berries.

Some produce, such as berries, cannot be washed and maintain shelf life before getting to consumers. That forces processors to take a different approach to safety. Photo courtesy of Getty Images/FlorianTM

As already mentioned, fresh produce has no kill step, so the key is to minimize the potential for contamination. Good agricultural practices include proper composting, maintenance of water quality used for irrigation and good hygienic practices by workers, in the field and the packing house. Most fresh produce is washed as part of processing and handling. (The word “most” is used since there are some items such as berries that cannot be washed.) Good sanitary design of the washing or fluming system, and the proper using of sanitizers, will clean the product and reduce the overall microbial load slightly. The washing step will physically remove bacteria from the surface of leafy greens. Once they are no longer attached to the fruit or vegetable, they can be killed by the sanitizer, provided the concentration and pH are adequate.

It is recommended that the washing step be validated. According to Gombas et al (2017), there are three options for validating the washing step. These are:

1. Use a surrogate for the microbial hazard and demonstrate that cross-contamination is prevented.

2. Use antimicrobial sensors and demonstrate that a critical antimicrobial level is maintained during worst case operating procedures.

3. Validate the placement of antimicrobial sensors in the processing equipment with the demonstration that a critical antimicrobial level is maintained at all locations regardless of operating conditions.

Treatments associated with kill steps such as the application of heat, chemical treatments such as polypropylene oxide used for seasonings and spices, or high-pressure processing simply cannot be used with fresh produce because the flavors and textures that are associated with freshness would vanish. Many have advocated the adoption of low-level food irradiation as a tool to help control bacterial pathogens, which are the most common cause of recalls and health issues with produce including fresh-cut products. This was especially true following the aforementioned 2006 recall of spinach contaminated with E. coli 0157:H7. There were many who advocated the adoption of this technology as a control for bacterial pathogens.

Low level irradiation plus current washing protocols with sanitizers may be able provide enough of a log reduction to enhance produce safety. However, there are still issues of consumer acceptance of food irradiation even though there are mountains of literature developed over the past sixty years on the safety of irradiated foods. Sadly enough, there are still some who believe in the “glow in the dark syndrome.” In addition, there are regulatory issues regarding both the installation and operation of irradiation equipment that have created barriers to adoption. In fact, at least one fresh-cut processor took a serious look at irradiation following the 2006 outbreak only to say “no thanks” following an overview of the compliance issues.

What’s new with produce safety?

The focus of food safety in the produce industry is really maintenance; that is, make sure that the programs that have been developed, documented and implemented are properly managed and maintained; or in other words, operators are properly verifying that they are doing what they are supposed to be doing. The United Fresh Produce Association (www.unitedfresh.org) routinely offers advice and programs targeted at helping their member and the industry as whole manage, maintain and upgrade their programs from crop management to harvest to processing and finally distribution. Management of water for both ensuring food safety and, in response to the drought and the continued emphasis on more efficient use of water, how to better manage a declining resource is one area on which the organization has focused.

The preharvest testing program, which targets salmonella and Shiga toxin producing E. coli strains such as E. coli 0157:H7, is a risk-based program, meaning it is up to the grower to determine whether there is a significant risk based on a number of factors.

Another is traceability and recalls, an area that the Association has emphasized since 2006. The approach to educating the industry has evolved over the years. Immediately after the spinach recalls in 2006, the technical staff instituted a series of seminars that focused on technical and regulatory issues needed by companies for building a recall action team and developing the procedures and in-house expertise to manage a crisis. They soon realized that they needed a third leg for these sessions: communication. So, the programs were expanded to include how to properly communicate during a crisis. There has also been an emphasis on sampling and testing both in-plant for managing Listeria monocytogenes as an environmental pathogen and testing product in the field. Now, this is a great segue into one of the new programs aimed at enhancing food safety; pre-harvest testing.

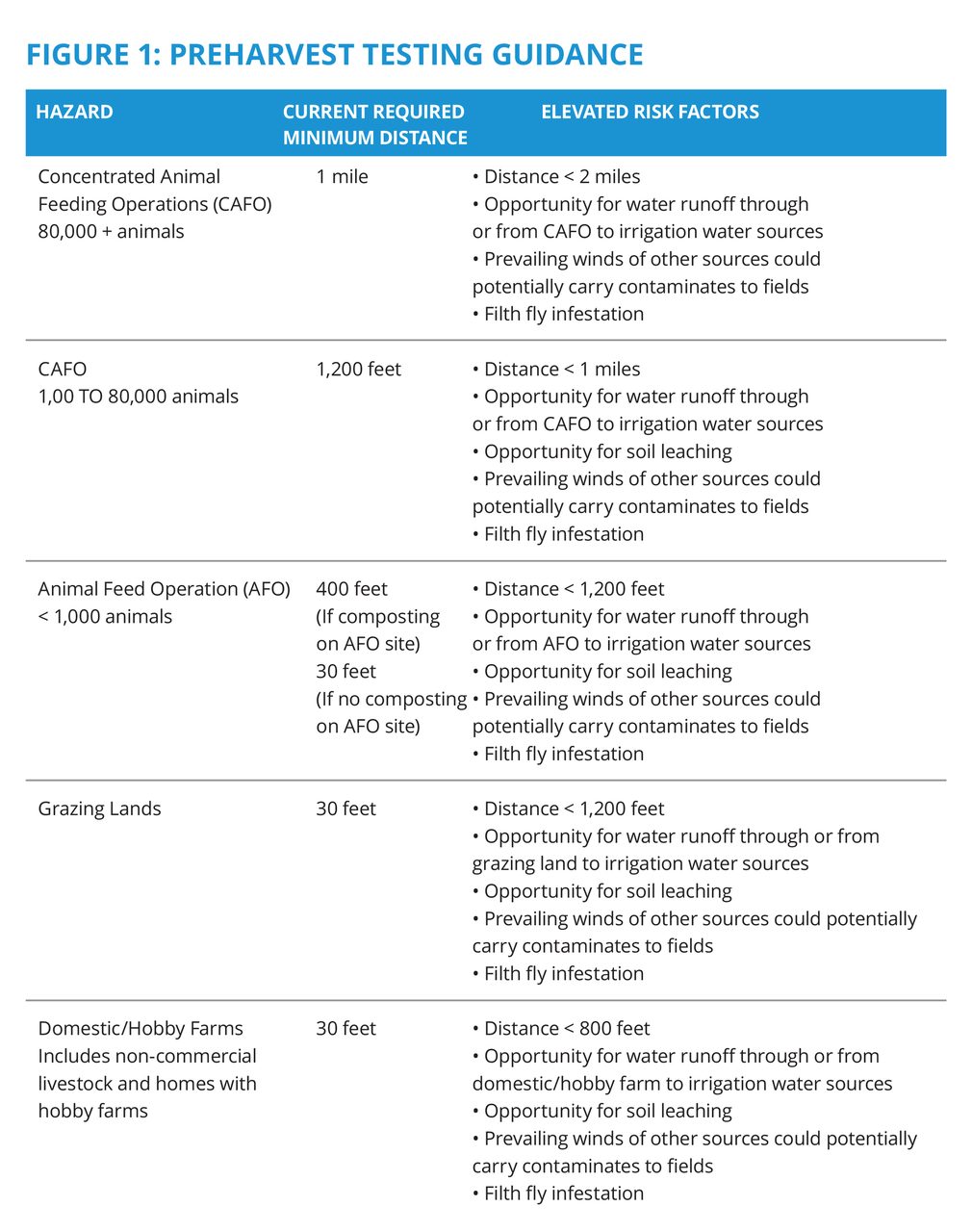

The LGMA, or Leafy Green Marketing Agreement (www.lgma.ca.gov), has developed and is implementing mandatory risk-based preharvest testing program for growers of leafy greens. The organization’s purview includes lettuce, cabbage, kale, spinach, escarole, chard and endive. The preharvest testing program, which targets salmonella and Shiga toxin producing E. coli strains such as E. coli 0157:H7, is a risk-based program, meaning it is up to the grower to determine whether there is a significant risk based on a number of factors. These include proximity to livestock especially feed lots, potential for fecal contamination of water sources or run-off, prevailing winds and filth fly infestations.

Now this is not new to LGMA members as demonstrated by a survey done by the group that indicated that the majority of their members are already doing pre-harvest testing. Figure 1 summarizes the LGMA’s recommendations for pre-harvest testing on fields based on the risk factors described in the figure. Fields with elevated risk levels will have to collect sixty (60) samples totaling a minimum of 1,500 grams on a one-acre plot. These samples must be collected and run between 4 and 7 days prior to harvest. The sampling plan is based on tables developed by the International Commission on Microbiological Specifications for Food (ICMSF). Sampling programs are not mandated but must be developed by each company with the testing laboratories using the aforementioned guidelines. The confidence levels are estimated to provide a 95% chance of detecting pathogens even at contamination levels of as low as 1% according to Tim York, the Chief Operating Officer of the LGMA. If a sample is found to be positive, the LGMA mandates for the grower will include a root cause analysis to determine the source of the pathogen and that that lot not be used for the fresh market. (Learn more about pre-harvest sampling on YouTube at https://youtu.be/ER1dOXrd8CI.)

“I think it does have merit,” says Dr. Jennifer McEntire, chief food safety and regulatory officer, United Fresh Produce Association. “The 95% comes from the ICMSF tables, and depends on % contamination, which of course, in actuality we don’t know. If testing is meant as verification of controls—and the industry thinks they have the right controls in place, then this is where testing might help focus efforts on things that were overlooked or simply not realized.”

Dr. McEntire makes an excellent point when referring to pre-harvest sampling as a verification activity. Remember your HACCP history; the program was initially developed for the space program and recommended by the National Academy of Sciences (NAS) group in 1985 as the best means of managing microbiological hazards because “Testing of finished products was not an effective means of protecting the consumer and assuring the foods were free of microorganisms of public health significance.” This was the same conclusion reached by NASA, Natick Laboratories and Pillsbury back in 1959. NAS also said: “HACCP provides a more specific and critical approach to the control of microbiological hazards than is achievable by traditional inspection and quality control.” In other words, build safety into the process, in this case growing leafy greens, which the members of the Leafy Greens Marketing Agreement and United Fresh are doing.

Another area that the produce industry is looking at is what some have called visibility in the cold chain. Some estimate that up to 1/3 of fresh produce globally is lost, a figure that could be improved given greater monitoring and control throughout the cold chain. This would also enhance food safety. The Sanitary Transport Regulation mandated temperature monitoring of shipments for which proper temperature control was deemed essential for ensuring food safety. The smart businessperson should mandate temperatures be monitored on each and every product that must be shipped under refrigeration.

In most cases, temperature monitoring is accomplished through recorder charts mounted on the refrigerated container. There are some who take this a step further, with temperature monitoring done remotely. This is one of the features that the Klinge Corporation has installed on many of their refrigerated containers. Shippers can monitor the temperatures in containers that are on the road, rail or water. Temperature deviations can be detected quickly, as can alarm from the refrigeration unit or notification of when the unit is turned on or off, so emergency steps taken to minimize or prevent losses. When the transmitter is in cellular tower range the transmissions would be done that way, and if the container is in areas with no cellular coverage the transmission changes automatically to satellite. That also covers ocean voyages. This kind of monitoring is the wave of the future.

The produce industry is a multi-billion-dollar industry. The goal is to get high quality, good tasting products from the field to the consumer as quickly and as safely as possible. However, being a raw product that grows in fields or orchards where it could be exposed to pathogenic bacteria from the air, through water or via contact with people, animals or insects, there are occasional recalls and/or outbreaks due to pathogenic bacteria such as salmonella, listeria or dangerous strains of E. coli. The industry mantra is keep the product clean, keep it cold and move it quickly.

In the 30 years since the fresh-cut industry has emerged, there have been some hard lessons learned. Perhaps the greatest challenge is that there is no kill step that can be applied to produce, so it is up to growers, handlers, packinghouses and processors to do all they can to minimize the potential for cross-contamination. This encompasses programs in the field—that is Good Agricultural Practices (GAP), Good Manufacturing Practices (GMP) and a range of other programs especially monitoring and maintaining water quality. The industry is always on the lookout for new technologies or practices that will help ensure safety. One of these will pre-harvest testing; a program designed to verify GAP designed for leafy greens. The industry is committed to continuous improvement and this is one more tool in the toolbox. FE