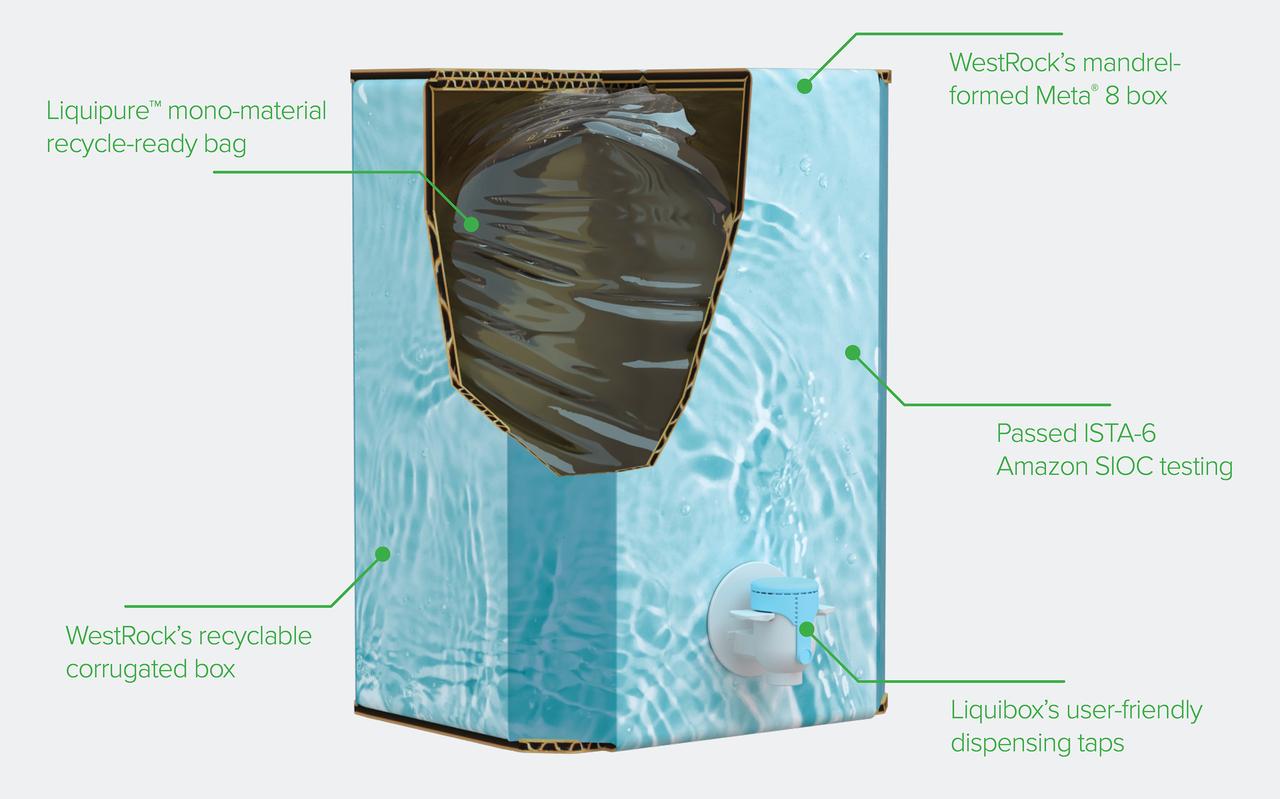

New e-commerce solution for recycle-ready bag-in-box from Westrock and Liquibox. Photo courtesy of Liquibox/Westrock

Liquibox and WestRock have launched a Ships In Own Container (SIOC) bag-in-box solution for Amazon that reduces waste and ensures products arrive undamaged.

The combination of Liquibox’s recycle-ready Liquipure™ flexible packaging, its portfolio of dispensing taps and fitments, and WestRock’s high-impact Meta® box designs, has created an optimal e-commerce liquid format for beverage, liquid food and home-care brands that want to grow in online retail. Through this partnership, customers have access to a turn-key solution to start selling online that covers everything from packaging, service and testing needs to the filling and mandrel case-forming equipment.

The new recycle-ready bag-in-box solution is smaller and lighter than bottles, minimizing environmental impact by eliminating the need for void fill and overpackaging, as well as reducing transportation and storage costs. Following rigorous performance tests, the new packaging passed ISTA 6-Amazon.com-SIOC test in an Amazon APASS-certified lab and therefore does not require additional protective boxes.

Liquibox and WestRock deliver e-commerce solution for liquids

MULTIVAC’s full-wrap egg packaging labels provide efficiency and a secure seal. Photo courtesy of Multivac

MULTIVAC is redefining fresh egg packaging in boxes or plastic trays with its L 310 full-wrap labeler. The L310 machine creates an attractive package and closes it with a secure seal.

With its L 310 conveyor belt labeler, MULTIVAC now offers an efficient solution for labeling egg packs made of cardboard or plastic. The L 310 makes automated C and D labeling (as well as traditional top labeling) of packs possible at an output of up to 120 packs per minute. The maximum label width is up to 500 mm.

When the L 310 is used for complete wrap-around labeling, the full wrap label automatically seals the egg box. For retailers and consumers, this means that the products cannot be exchanged or contaminated with viruses and bacteria, or that the packs cannot be used to hide stolen products. This solution is the ideal choice for aseptic or pasteurized eggs.

As well, label shape, material type and printing can be individually tailored to the pack.

Full-wrap labeling solution for egg packs

Actega created Signite to reduce label waste on containers. Photo courtesy of Actega

An alternative to the no-label look

ACTEGA, manufacturer of specialty coatings, inks, adhesives and sealing compounds for the print and packaging industry, launches Signite™—a revolutionary, ACTEGA patented, premium decorating solution designed to significantly reduce waste in label production. Depending on the decoration design, the technology can reduce label waste by over 50% compared to a similar footprint pressure sensitive label by elimination the label matrix, reducing the decoration thickness to about a third of that of a typical clear pressure sensitive label and eliminating label media plastic in non-print areas.

Signite decorations contain less material mass than alternative decor and is more accommodating to current recycling processes. The new decorations represent an alternative to “no-label look” labels, bringing the look and feel of direct-to-container screen or digital printing with the efficiency of pressure sensitive labeling.

Transfer of the Signite decorations to containers requires designed-for-purpose variations of pressure sensitive labeling equipment. The first Signite in-line applicators launched into the market address rigid cylindrical containers at lower throughput speeds. Subsequent system designs, in different stages of prototype development, will address aluminum and asymmetrical containers along with thin-walled container types requiring inflation for decoration transfer. High-speed Signite applicator machines and decoration are anticipated to move into prototyping in 2022.