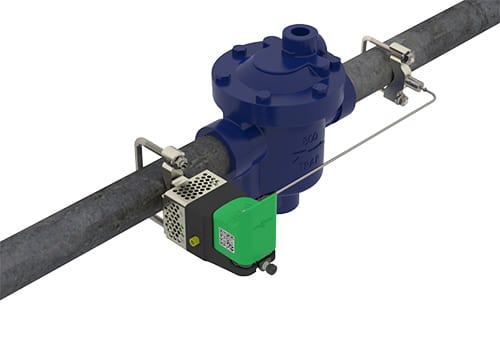

With the support from Armstrong International, a leading thermal utilities company, Everactive’s continued growth shows no signs of slowing down. Its new generation batteryless IoT system for steam traps delivers wireless non-line-of-sight communication up to 820 ft. (250 meters)—using the Evernet 2.0 wireless network—allowing for coverage of a larger percentage of steam traps with fewer gateways required throughout a facility. The company has increased the capacity of its IoT gateways to 1,000 Eversensors. Taken together, a single STM Eversensor can be installed on a steam trap and setup in the cloud, combined with SAGE, the most advanced steam trap thermal utility software, in less than five minutes. This innovative technology only expands Armstrong’s existing partnership with Everactive, combining its deep thermal expertise with Everactive’s technology to make steam systems smarter.