Gentle grippers can pick up food items on a belt, but to do it well, there must be a fast-thinking “brain” behind their moves

Soft-touch robotics system becomes human-like with new AI software

Robotics systems lately have developed a soft touch to pick up delicate foods without damaging them, and there have been a lot of developments in the grippers themselves to handle these fragile products. However, these grippers can’t do it alone; they need help from 3D vision systems and a “brain” to interpret the sighting of products on a conveyor belt and coordinate the gripper to pick up and move the delicate food item safely and quickly—without damage.

One company that’s been instrumental in the development of this intelligence—based on artificial intelligence—is Soft Robotics, which has been covered in Food Engineering recently. This company has also caught the interest of investors, including Tyson Ventures, which sees the need for robotics systems that not only handle delicate food items safely, but also pick up various shaped products—such as chicken breasts or drumsticks—coming down a conveyor.

“At Tyson Ventures, we are continually exploring new areas in automation that can enhance safety and increase the productivity of our team members,” Rahul Ray, senior director of Tyson Ventures, says. “Soft Robotics’ best-in-class robotic technology, computer vision and AI platform have the potential to transform the food industry and will play a key role in any company’s automation journey.”

Mark Chiappetta, chief technical officer, Soft Robotics

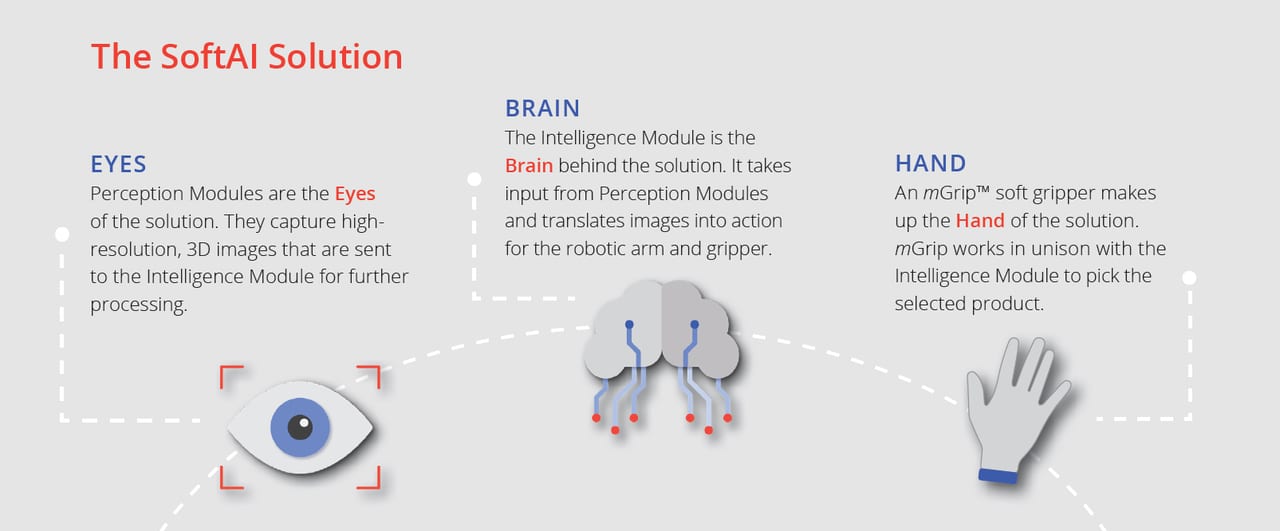

SoftAI is a bundled hardware and software solution comprising an mGrip soft gripper and controller, one or more 3D Perception Modules (PMOD) and an Intelligence Module (IMOD). Photos courtesy of Soft Robotics

vision Indeed, Soft Robotics has garnered $10 million in investments to further the development and launch the company’s SoftAI powered robotics solutions. SoftAI layers 3D vision and artificial intelligence technologies on top of Soft Robotics’ patented and proven, IP69K-rated, soft grasping to give industrial robots the hand-eye coordination of human beings. This combination of robotic “hands,” “eyes” and “brains” enables the automation of bulk picking processes (e.g. bin picking) in the food supply chain.

“Today’s industrial robots are unable to deal with product variability or unstructured environments typically found across the labor challenged food supply chain in areas such as agriculture, food processing and logistics,” says Mark Chiappetta, chief technical officer at Soft Robotics. “With our soft grasping, 3D perception and AI technologies, Soft Robotics unlocks robotic automation by augmenting widely available industrial robots with true hand-eye coordination allowing them to perform tasks that traditionally could only be performed by human workers.”

I spoke with Chiappetta to find out where Soft Robotics is headed with this new technology.

FE: What has been driving this development effort to come up with an intelligent, soft-touch gripping system—hardware and software?

Chiappetta: For as long as anyone can remember, the global food industry has been critically dependent on labor to keep its operations running and to meet an ever-increasing demand for safe, sustainable and nourishing food products.

At the same time, the food supply chain is being stressed by challenges with worker availability caused by an ageing population, upscaling of the workforce and most recently, the COVID-19 pandemic.

Other industries rely heavily on robotic automation to meet these challenges. However, today’s industrial robots lack the dexterity, perception and cognitive skills of human workers and thus, are unable to handle delicate, variable items in the often-unstructured environments found in food production and processing.

This reality is what has been driving Soft Robotics to develop and bring to market SoftAI—an integrated picking solution comprising industry-proven soft grasping, 3D perception and artificial intelligence software. SoftAI gives industrial robots the necessary hand-eye coordination to make them a viable alternative to labor.

FE: Soft Robotics started out building a soft-touch gripper, the mGrip, correct? Are grippers the key part of your business?

Chiappetta: At the very foundation of a SoftAI Solution is our patented and industry-proven soft gripping technology (mGrip). To enable robots with the hand-eye coordination of a human worker, we must first give them the ability to handle delicate, variable food products in a sanitary way. This is exactly what mGrip was designed to do and why it has proven its value to hundreds of global customers over the past seven years.

FE: Was the mGrip designed for a specific brand or type of robot, or was it a more general design?

Chiappetta: The design goal for the mGrip system was to have it be “robot agnostic.” Today you will find it running 24/7 production on almost every brand of delta and 6-DOF (degrees of freedom) robot arm available.

Soft Robotics’ food-grade soft gripper technology (mGrip) allows robots to safely and efficiently pick and pack singulated and bulk food products.

FE: When did you begin designing SoftAI? Did you start at the same time you were developing mGrip?

Chiappetta: Our soft gripper technology became commercially available in 2015, and almost immediately, we started to get customer feedback requesting help with “bulk” picking challenges—such as picking produce from a bin, chicken parts from a moving conveyor or bakery products from totes.

By 2016, we felt that we had clear enough of a market signal to immediately begin development of the software component of SoftAI—the 3D perception and AI stack that today layers on top of our mGrip soft gripper technology.

FE: Besides the main driver of our industry needing a soft touch for handling delicate foods, what were some seemingly insurmountable issues that food manufacturers need to overcome with this technology?

Chiappetta: As I stated earlier, human workers have a keen ability to handle delicate, variable items found in food processing and production operations. However, this ability extends beyond just having the right “hand” for the job. In fact, without strong perceptual and cognitive abilities, even humans wouldn’t be able to perform even the simplest applications. This is where SoftAI comes in. With SoftAI, automation system integrators can design and deploy robotic solutions that meet the needs of food producers.

SoftAI comprises a three-part system that mimics the way a human works to pick up sensitive food products.

FE: What hardware does SoftAI run on? Do you build the controller, or is it an OEM item?

Chiappetta: SoftAI is a bundled hardware and software solution comprising an mGrip soft gripper and controller, one or more 3D Perception Modules (PMOD) and an Intelligence Module (IMOD).

Perception Modules are the “eyes” of the system and incorporate multi-modal sensing and powerful onboard computation in a food-grade, stainless steel, IP69K enclosure.

The Intelligence Module is the “brain” of the solution. It is a powerful, connected AI computer in an industrial-grade enclosure that takes information from multiple Perception Modules and grasps information from an mGrip gripper controller to execute high-performance picking and placing of food product in unstructured environments.

FE: Do you recommend a specific vision system to be used with SoftAI and mGrip?

Chiappetta: SoftAI incorporates Soft Robotics’ proprietary vision hardware and software system—the Perception Module (PMOD). Each PMOD has a comprehensive understanding of the physics of soft grasping embedded into it. It uses this understanding to analyze each complex scene, identify an object to be picked and placed, and to establish the optimal grasping and release solutions to ensure successful task execution.

FE: Do you design and build a robotic cell with a robot, mGrip, vision system and controller to be sold as a single package or is that the role of a system integrator or business partner?

Chiappetta: Soft Robotics sells mGrip and SoftAI Solutions to automation system integrators and OEM machine builders to be incorporated into their larger solutions.

“Today’s industrial robots lack the dexterity, perception and cognitive skills of human workers and thus are unable to handle delicate, variable items in the often-unstructured environments found in food production and processing.”

— Mark Chiapetta, chief technical officer, Soft Robotics