warehouse data with production and business systems

Connecting

Making the connection provides up-to-the-minute data on scheduling, stock-outs, ingredient substitutions, customer trends and recalls

Most likely you have an ERP system running your business, which may consist of many modules including, for example, customer relationship management (CRM), inventory systems, scheduling, ledgers, track-and-trace functionality and possibly some sort of warehouse management system (WMS). Depending on your needs or the timing of your software purchases, you may also have a shop floor or MES (manufacturing execution system) and a standalone WMS—which may or may not be connected to your ERP system. Often one role of a shop floor or MES is to act as a relay or connection point between the ERP and WMS. In case of a non-automated shop floor where there is no MES, there is a good chance that the ERP system connects with an independent WMS or has some built-in WMS functionality.

Our focus is to look at the connection between production/business (MES)/ERP systems and the WMS and understand how they function together to keep you abreast of ingredient shortages, customer/consumer issues and potential recalls due to a quality/food safety issue.

Getting to know the lay of the land…or cloud

Like the pharmaceutical industry, food and beverage is highly regulated, which means a well connected facility—business, production and warehouse—is a given because track-and-trace and electronic records are a requisite. Most ERP and production management software suppliers understand a tight connection to warehouse activities is more important than just knowing there is enough inventory to cover the next production run. In several cases, these suppliers provide specialized WMS offerings to meet food industry requirements. Most ERP applications are so modular that they can be tailored to any-sized food and beverage processor.

Wayne Labs, Senior Technical Editor

Photo courtesy of Getty Images/nortonrsx

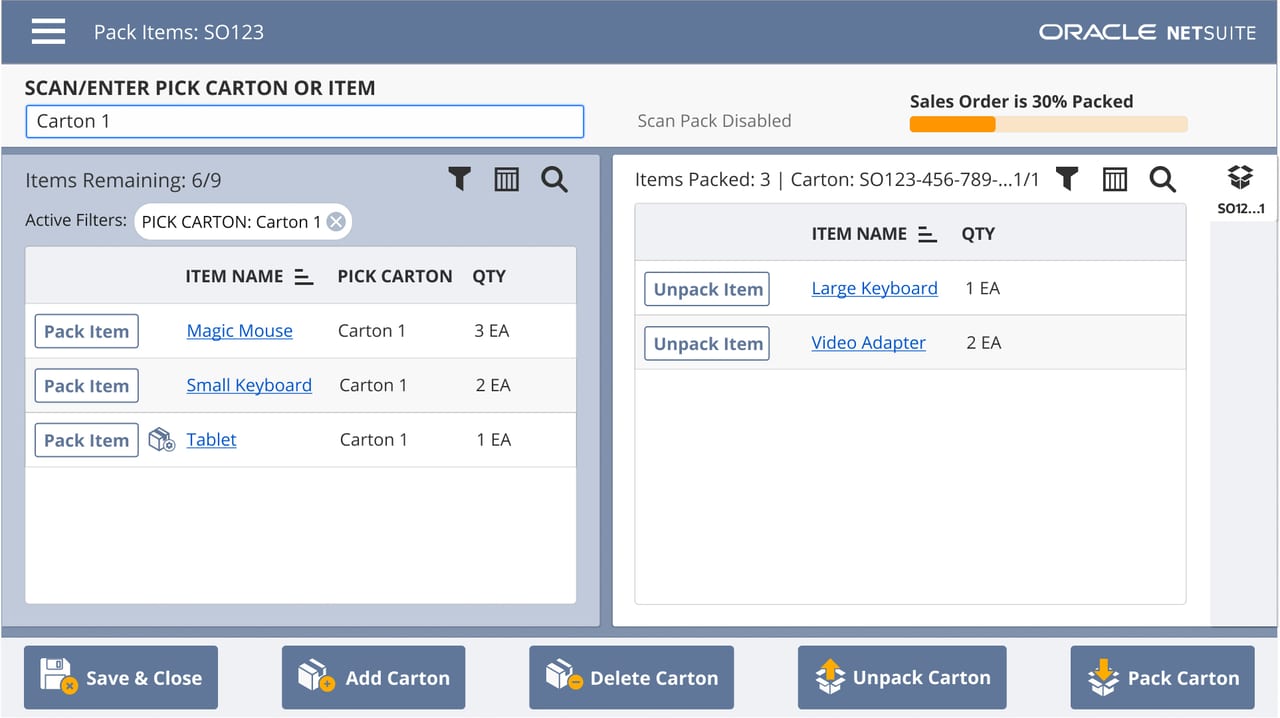

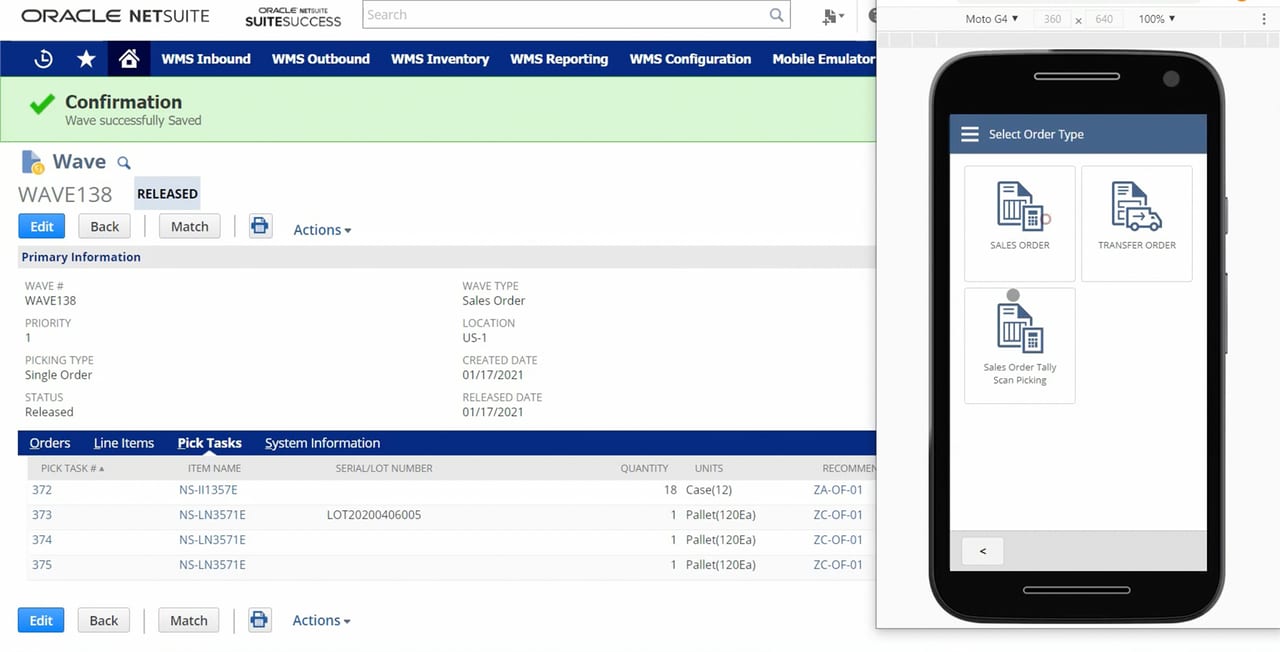

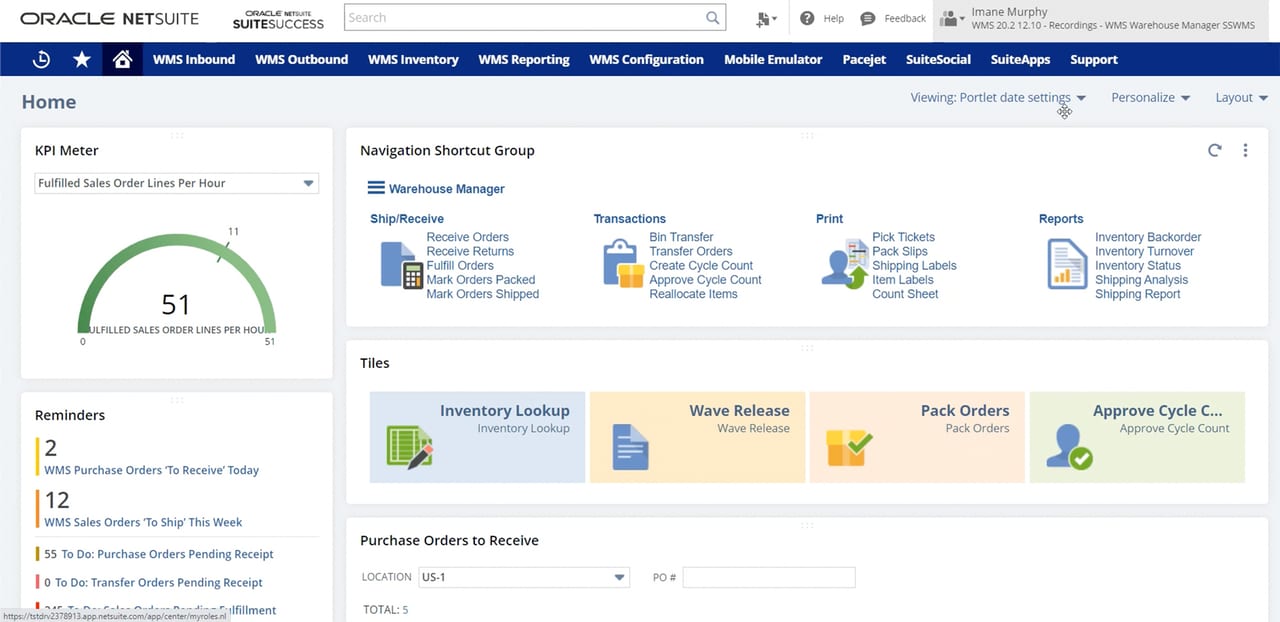

Oracle NetSuite WMS App helps businesses keep track of wave picking, tally scans, cart put-away, label printing and more through tablets and smartphones. Screenshot courtesy of Oracle NetSuite

Many ERP/MES/WMS suppliers today offer both on-site and cloud-based systems, and both approaches have their unique advantages and disadvantages, which we won’t cover at length here. Suffice it to say, cloud-based systems require a smaller hardware investment, but could potentially suffer from internet outages, while on-site systems tend to be more expensive to maintain, but they keep on running should the internet go down. For more on this subject, see “IIoT and the Cloud,” a Food Engineering web exclusive.

One benefit of a cloud-based application is that it works everywhere on most any device and is configurable specific to a user’s needs. “Oracle NetSuite is a complete cloud-based business management suite that covers all aspects of the business from CRM, commerce and financials to inventory, manufacturing, order management and WMS,” says Gavin Davidson, industry product manager. “We also offer a number of mobile applications that run on the same platform: MES, quality, WMS and packing station. The breadth of our solutions allows customers to gain complete visibility and control into their business operations and provides them the ability to automate business processes across the entire suite.”

Speaking of cloud-based systems, Plex Systems is an early cloud pioneer, delivering completely cloud-native solutions for ERP, production/manufacturing execution, and warehouse operations. According to Jim Bresler, director of product management, food & beverage, Plex has been able to achieve cloud uptimes of 99.997%, which works out to about 15 to 20 minutes of downtime per year—probably better than your electric utility service.

Cloud-based software is sometimes thought to have security issues, but Bresler says Plex has achieved top security ratings (securityscorecard.com “A” rating). Being cloud-native, the software is browser-based but also offers a mobile app scanning solution for both production and warehousing, which runs on iOS, Android and Windows devices.

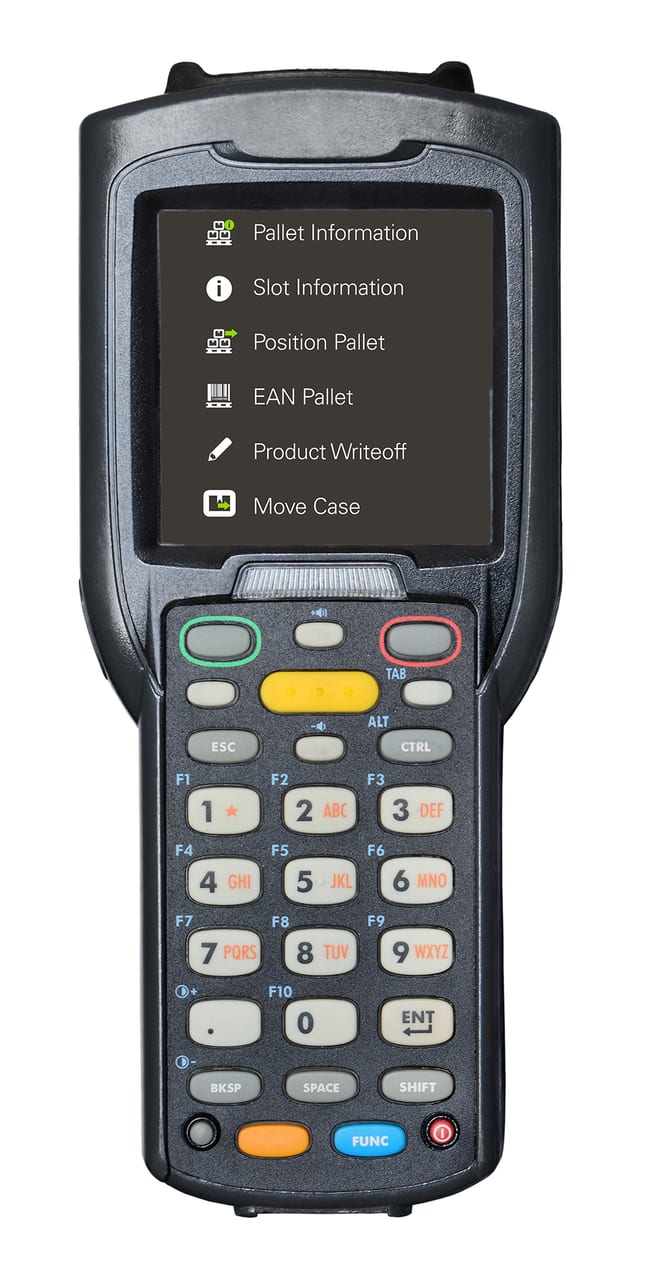

Warehouse personnel using CAT Squared’s WMS running on wireless handheld devices, can input product data via barcodes or get pertinent data about products stored in the warehouse. Photo courtesy of CAT Squared

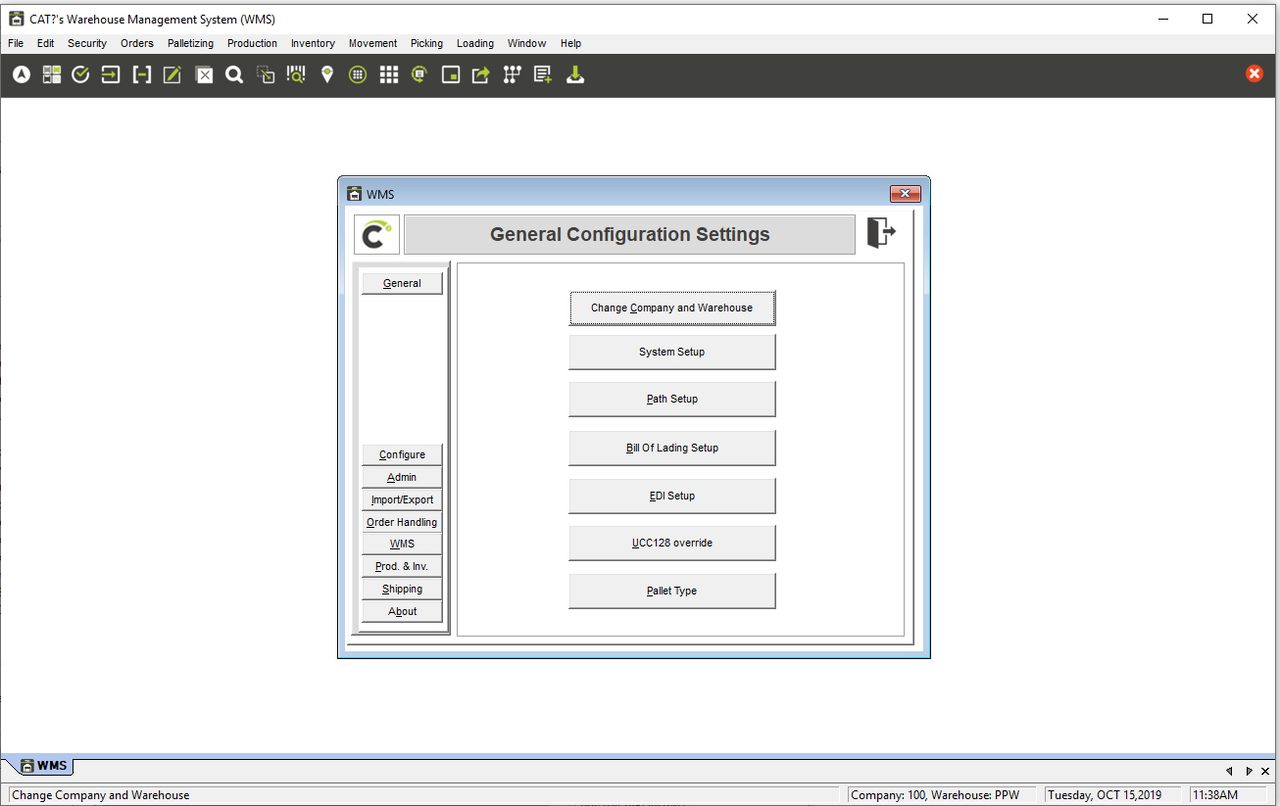

CAT Squared’s systems are hardware agnostic, but typically utilize industrial PCs on the plant floor and mobile handheld devices to perform WMS functions such as configuration. These devices interact with on-premises or cloud-based application and database servers. Photo courtesy of CAT Squared

Food-industry specific applications

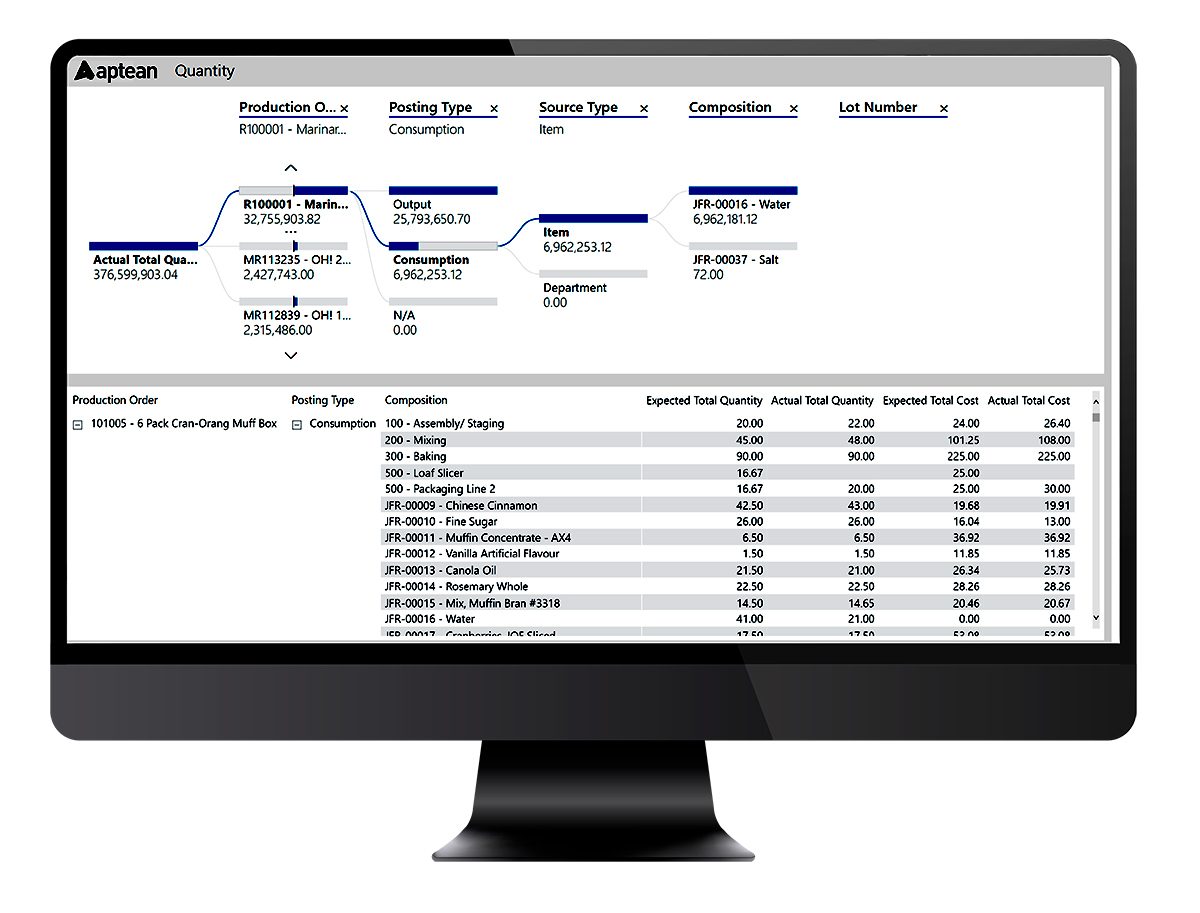

“There are few industries in which achieving tight synchronization between production and warehousing matter more than in food and beverage manufacturing,” says Jack Payne, Aptean director of solutions consulting, food and beverage. While having different, specialized systems can drive functional benefits, it can often come at the cost of tightly linking production and warehousing operations in real time. “That’s why we have taken the approach of ensuring that Aptean Food and Beverage ERP includes both highly specialized food and beverage production functionality and built-in warehousing capabilities,” he adds.

Real-time synchronization of master data (customers and products) and transactional data (inventory, lots, shelf life) between an ERP solution and a WMS solution is often very challenging to achieve, says Payne. Without this synchronization, the sales department could promise inventory that has already been shipped to someone else, and the planning staff could either over-produce or under-produce supply to fulfill demand, leading to short shipping customers or potential expired product.

In the food and beverage industry, the need for complete traceability from supplier and supplier lots to customers and customer shipments, and integration of the two systems can put this mandatory requirement at risk. That is why having a specialized food and beverage ERP system that includes warehousing and distribution capabilities rather than two separate systems is ideal, explains Payne.

Aptean’s Food and Beverage ERP can synchronize the WMS with production and business systems to get a handle on what the cost will be to make a particular batch, based on fluctuating prices of ingredients and manufacturing costs. Screenshot courtesy of Aptean

Our IFS Cloud single platform solution seamlessly connects all industry specific products and capabilities required by food and beverage manufacturers,” says Andrew Burton, global industry director - manufacturing at IFS. IFS Cloud is configurable, and the modules IFS users choose can be deployed either in the cloud or on-premise. Capabilities include not just production and warehousing operations, but also the ability to integrate all aspects of the day-to-day running of a business. IFS Cloud offers solutions for CRM/marketing, demand planning, production, warehousing, asset and service management, and includes specific functionality around shelf life, expiration, etc.—all of which are crucial to the industry.

Infor provides industry cloud solutions specifically designed for food and beverage manufacturers and distributors, says Marcel Koks, industry strategy director, food & beverage. Most processors opt for a public cloud deployment, but an on-premises system is a possibility as well. Depending on the needs and current application landscape of a client, the solution can be composed of Infor ERP with its embedded WMS capabilities or extended with the advanced Infor WMS. Regardless the choice for ERP, WMS or both, the solution comes with an integration layer, called Infor OS, to synchronize ERP, WMS and WES (warehouse execution system). The integration makes use of REST APIs.

REST APIs (application programming interfaces) provide a flexible, lightweight way to integrate applications, and have emerged as the most common method for connecting components in micro-services architectures, according to IBM. A REST API is an API that conforms to the design principles of the REST, or representational state transfer architectural style. [1]

Sage X3 is an enterprise-wide blend of applications that addresses the unique and specialized needs of food and beverage manufacturers, says Mike Edgett, director of product marketing. The functionality of X3 covers the critical components of F&B companies, such as formula management, lot control and tracking, allergen management, quality management, regulatory compliance, batch processing, quality assurance, scheduling, warehouse mobility, inventory management and expiration control. These functions together synchronize manufacturing and the warehouse to ensure the best raw materials are available at the right time while controlling overall costs.

While CAT Squared doesn’t have a dedicated ERP system, it does have MES and WMS systems. “CAT Squared’s solutions are specifically designed for the food and beverage industry and include comprehensive modules for both production and warehousing,” says Karen Lambert, Sr., WMS software engineer. When CAT Squared’s MES and WMS are both implemented for a company, the need to interface information between the two is inherently eliminated, as the modules seamlessly work together as one comprehensive, tightly integrated system sharing the same database.

Oracle NetSuite Dashboard shows Warehouse Manager’s functionality, which includes shipping/receiving of orders, transactions, reports, inventory lookup, pack orders, and a KPI meter. Screenshot courtesy of Oracle NetSuite

When the MES or WMS is independently implemented, CAT Squared offers full integration capabilities for communicating data from, or to, the plant floor or warehouse. A dedicated integration team would also work with the user and third party to map data, perform a gap analysis and apply any needed customizations.

“CAT Squared’s systems are hardware agnostic, but we typically utilize industrial PCs on the plant floor and mobile handheld devices to perform WMS functions,” adds Lambert. “These devices interact with on-premises or cloud-based application and database servers.”

MES: A natural link between ERP and WMS

“Normally ERP is the system of record for the master data, purchase orders, production orders and sales orders,” says Jerry Beaston, Infor product manager WMS. ERP is also controlling the planned dates and times of these transactions. Planned material receipts, ASNs (advance shipment notice), picking orders for material to production, ASNs for outgoing products from production and picking orders for sales orders are sent to WMS, which is executing these.

The main objective of a WMS is to provide the necessary tools to control and optimize the storage and movement of inventory in a way that maximizes efficiency and minimizes cost, adds Lambert. Receiving, put-away, picking, shipping, cycle counting, reporting and interfacing capabilities are all primary components of a WMS.

While an ERP system can link to a WMS, Lambert says the linking should be the job of a MES if a WMS is already in place. Most major ERP systems provide interfacing capabilities needed to interface with plant-floor MES; however, linking production inputs and outputs to WMS systems is typically an MES function, utilizing native or third-party interfaces to provide necessary data to the ERP.

“There are few industries in which achieving tight synchronization between production and warehousing matter more than in food and beverage manufacturing.”

— Jack Payne, Aptean director of solutions consulting, Food and Beverage